Split Casing Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Split Casing Water Pump for Farm Irrigation

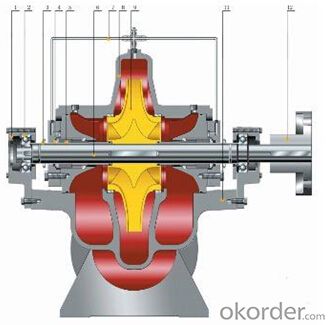

1.Split Casing Water Pump for Farm Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Water Pump for Farm Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Water Pump for Farm Irrigation Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Water Pump for Farm Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: on my 92' toyota celica, i got the heater core by pass fixed and also a new radiator because both were leaking, and now my mechanic tells me i also need a new water pump , which can be really expensive! apparently it is leaking water too, so i was thinkng just filling up my car with water before driving until i can afford to get it fixed.. can this shortcut be done to prevent my water pump causing me further problems?

- You can do that, but you can't fill it with pure water because in time you'll have only water in the system which can cause problems. Antifreeze also increases boiling point of the water/antifreeze mixture thus protecting the engine... You should always add 50/50 mixture. Anyway, bad pump is generally bad for cooling. It is better to have leaking radiators than bad pump.

- Q: i want to make this for a physics project for school. i found a video on how to make it, but i dont understand the physics behind. i have to make a model and a poster explaining the physics. i dont understand what to put on the poster so could someone help me with which physics principles this project would go with?

- It isn't practical to give a detailed description here. This is a positive displacement pump. The pump chamber is sealed so that as the piston is moved up the volume within the chamber increases. Water is pushed into this chamber by the outside air pressure. If the pump is located too far above the water source then the air pressure is not sufficient and you will produce a vacuum inside but the water still will not flow. When the pump is pushed down the water flows out. Now the one way valves are critical. We don't want the water to flow back the way it came and we don't want the water that we have already pumped to flow back into the pump. So a one way valve on the inlet will permit water to flow into the pump but not out of it. And a one way valve on the outlet will permit water to flow OUT of the pump but not into it. So with each stroke you a) reduce the pressure in the pump. b) water is forced from the inlet, past its one way valve and then into the pump. c) the pump is pushed down increasing the pressure in the pump. d) water flows out of the pump through the other one way valve and on to the output.

- Q: I have an 1985 cadillac fleetwood hearse and the water pump is shot to hell. where do get a good cheep one.

- any okorder and find the closest location. they are the cheapest option unless you just want to push the car and then that wouldn't cost you anything now would it.

- Q: i started backing out of my garage and something sounded like it poped then lots of steam started coming out and water was on the ground on the right side of the car non on the left and the water pump needle in my car is all the way to the red can some one help me

- need new water pump if that is where it leaked from but most likely the hose blew on it check it out before water pump

- Q: What is the easiest way to remove a water pump?

- drain radiator. remove both 21mm motor mount bolts from subframe (front and rear). drain radiator. remove overflow/washer bottle. remove drive belt. remove 8mm bolt that hold lower watertube to front cover. remove lower water tube from water pump. remove heater hoses from water pump. slightly lift engine with floor jack. remove water pump pully. remove water pump. if you still cant get it you will need to remove the 4 studs that go through the water pump. now its just that easy to do

- Q: It stops and every few minutes and when it stops, it sounds like water is running.

- Ok lets go down the check list. 1) Is your cut off switch working good? Turning on and off at proper set pressure. (I don't know what you may have yours adjusted to. Mine is on at 70 off at 95.) 2) Is your expansion tank (or pressure tank) water logged? Knock on it. Does it sound full or partially full. Full is bad. You will need to shut off the water pump, close off any outgoing ports to the rest of the house, open the drain valve nearest that tank, and press your finger into the shraider valve at the top (the thing that looks like a tire stem valve). Drain the tank only. Then turn the water back on. 3) Do you have water softeners hooked up? Listen closely to the discharge tube. (this may be where it is coming from). IF you hear a leaking it is because the valve spring inside and washers need to be replaced. 4) do you have any other whole house filters? If so check the discharge tubes of them. 5) Do you have a reverse osmosis filter? IF so this is supposed to drain and you will hear it constantly. 6) Look for any water puddles 7) IF all these fail, then replace your water pump.

- Q: i just moved into a house that has a small (about 40 gal) pond. i wanted to put fish in it. i have everything but the water pump. i've been looking around and i've found many solar fountain heads (about $30) that are pretty cheap and then i found a solar oxygenator for $100. which one would help the fish more? flowing water or just oxygen?

- To be quite honest, they are roughly the same thing. For a small pond all you need is something to agitate the surface of the water. the carbon dioxide/oxygen exchange only occurs on the surface therefore a small fountain that agitates the surface would work, or a small air pump that causes bubbles. Both are just fine.

- Q: What is the difference between a sewage pump and a clean water pump? Why can't sewage be pumped with clean water?

- In short, the main difference between clean water pump and sewage pump: impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.2. in order to prevent the wound, water pump impeller design is more simple but not ring pump, equipped with tips, cloth and other debris can be crushed after the pump, and the impeller water pump is relatively complex, but the efficiency will be significantly higher than the former.3., in order to prevent wear and corrosion, sewage pumps generally use better wear resistance, corrosion resistance, mechanical seal and O ring as the seal of water pumps, and clean water pump without strict consideration.To sum up, we can get a very good understanding of why not water pump sewage problems -- characteristics of channel and the impeller and other key design, resulting in water pump for sewage situation is likely to occur, blocking, winding, wear and corrosion occurs, resulting in damage to pump or scrapped, so water pump can not be used sewage.

- Q: We recently fixed our stone water fountain, and now we're trying to get it working. THe pump we had was about 5 yrs old, and didn't work. We've tried to get a new one online, but it only had one inlet for the water to go into the pump, and that got clogged in a matter of about 5 minutes. Since our garden has many trees, it's almost impossible for us to keep the fountain 100% clean all the time to prevent clogging. Anybody know where to get a pump for a 15gal fountain, that has multiple inlets?

- www.okorder

- Q: Why should the water pump be opened in time after the pump is started?

- The circulating water pump outlet valve is closed when starting, normal after the water outlet valve is opened, I found that, with the valve opening, the current is slowly sinking, you tell me why?, and the other is the opposite of the pump (with the valve opening current increases).

Send your message to us

Split Casing Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords