Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

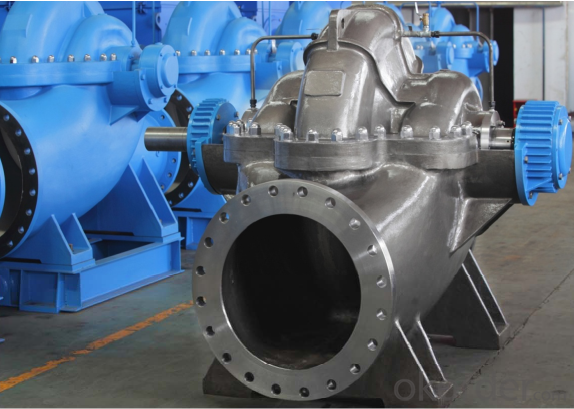

Split Casing Double Suction Centrifugal Water Pump for Irrigation

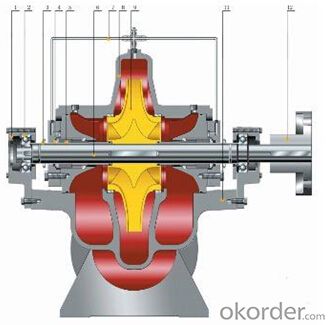

1.Split Casing Double Suction Centrifugal Water Pump for Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Double Suction Centrifugal Water Pump for Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Double Suction Centrifugal Water Pump for IrrigationSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Double Suction Centrifugal Water Pump for Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: I need a 12v water pump capable of at least 40psi. The only website that i found is one where you have to order a minimum of 100.

- Maybe at a sporting goods store.

- Q: Okay heres the deal Its knockin and I tthink the water pump is going would this be a cause of this and when it heats up it knocks but when its cold it doesnt knock also once it gets hot it shuts off and starts to smoke what could this be is it maybe the waterpump when I try to re start the car after it shuts it self off it only just clicks wount turn over thanks

- I'm sorry to tell you, but from your description it sounds as if you have major internal engine damage. A water pump just won't cause the symptoms you are describing. I'd have to say your engine is close to seizing up entirely - the knocking sounds like rod knock in the bottom end of the motor.

- Q: My car started to leak anti-freeze Really fast, so i had to pour water in there to keep it from overheating, so i took it to my mechanic, and left it there overnight, and they call me the next morning and tell me that the water pump needs to be fixed, and a few belts got water damage on them, and a a few driving belts need to be replaced. he said it would come out to be 695.97, does that sound like the right cost?

- actual okorder ....bet its 150 dollars..... around...u may get someone to do it for 400 to 500... water damage on the belts LOL,,,every time u go through a puddle they get water on them

- Q: i was coming home from from work and my jeep thew the serpenteen belt and my water pump is the only pulley not moving good like the rest and is leaking coolent. and people with just dump **** to say dont comment on this

- 1st off juan needs to get a life. now to help you .buy a haynes manual so you can go and do the removal and replacement of your water pump. step 1) remove the fan shroud 2) drain the coolant. make sure you do this so your critters won't drink it 3) remove the radiator. 4) remove the fan but do not remove the belt. this helps keep the fan from moving while you remove the bolts. if you have an electric fan remove this at the same time you remove the radiator 5) referring to the haynes manual remove any accessories that might be attached to the water pump 6) remove the pump. please refer to the haynes manual to insure you do the removal and re-instal correctly. oh yea, don't get fustrated . if you do just take a break. good luck and happy jeepin

- Q: I replaced the water pump on my 2001 dodge dakota and I still have a leak coming from somewhere. I don't know if i put the bolts in the wrong holes or what. Some bolts were long and some were short. Is there a diagram that shows where which bolts go where?

- no their isn't any diagrams on it but there is a way to identify them, just run them in the hole dry and see if they bottom out and do them one at a time,as a rule i always mark them when i remove them then this doesn't ever happen,but you can get them figured out by dry testing them and also look at the difference in the thickness on the water pump,good luck on it,

- Q: im thinking about buying a 93 ford taurus for $950. the owner says it will probably need a new water pump and brakes in the near future. is it worth it? i dont know anything about cars!

- in good condition (depending on the mileage) it may be worth a thousand dollars, but if all the brakes need doing and the master cylinder, and the rotors, that brake job and water pump could be almost as much as you paid for the car. And what is the guy so lazy or cheap he does not do repair work, ? I bet it needs tags soon too, this guy sounds like some cheap basshole, tell him to fix the car, and walk away from it any way, the transmissions were bad on the early 90s taurus, go with a later model after 97 they are much better, let this guy keep is crappy taurus, that he will not fix, and keep looking, patience, patience,patience is the name of the game for good cheap thousand dollar cars, and this is not the one. good luck

- Q: i have a 1990 honda accord, 2.2l 5 spd standard, and my water pump went on it, and i was wonder if there is a diagram out there somere on how to replace it or how to take it out, cuz it is in the most stupidest spot ever, if you know were i could find a diagram on how to do so could you please help me?

- You don't want to do it. Water pumps that are driven by the timing belts should not be done by amateurs since precise alignment of the camshaft(s), crankshaft, balance shaft, water pump is critical. You should really take it to a trusted mechanic otherwise you can put yourself in a world of hurt if you attempt it on your own. Does the term new engine mean anything for you? Not being rude, just honest.

- Q: My 1999 ford taurus WATER pump and serpentine belt need to be replaced because I can't stir the stiring wheel .... Would you know approximately how much this could cost so I dont get ripped off ??? I know nothing about cars... and this mechanic is saying between 300$ to 400$ and that is wayyy too expensive . It was kinda obvious to him that I know nothing about carsTHANKS A LOT!!!

- This Site Might Help You. RE: How much would it cost approximately to replace a water pump and a serpentine belt for a ford taurus 99? My 1999 ford taurus WATER pump and serpentine belt need to be replaced because I can't stir the stiring wheel .... Would you know approximately how much this could cost so I dont get ripped off ?? I know nothing about cars... and this mechanic is saying between 300$ to 400$ and that is wayyy...

- Q: HelloI am building a small budget underground room. On top of a very waterproof and airtight (besides vents) building, and running a dehumidifer inside, I would like to install a pump underneatth the foundation to suck out water from the soil surronding the building but I'm not sure what kind of pump would be best?Also how would b e the best way to set this up?

- What you want is called a sump pump. Most have a system built into them that is triggered by rising water. The idea is to have a hole beneath that allows the inevitable water that will collect a place to go, then when a certain amount gets in the hole, the sump pump comes on and pumps it out to wherever you have the hose or pipes ran to. Being underground, good luck keeping the humidity level down. It won't be easy, and much depends on where your natural water table is, and what it is during rains. Someone in your area might know all that, I don't.

Send your message to us

Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords