Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Double Suction Split Casing Water Pump for Pump Station

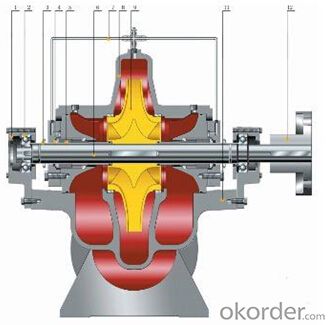

1.Structure of Single Stage Double Suction Split Casing Water Pump Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the Single Stage Double Suction Split Casing Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Single Stage Double Suction Split Casing Water Pump Images

4. Single Stage Double Suction Split Casing Water Pump Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: What are some good brands of aquarium water pumps? I have had bad experiances with Hydor Seltz (cheapest ones I could find, ugg, I know, you get what you pay for) pumps, failing very quickly, and sounding like plastic gears grinding around inside. What is the best kind to get?I need one that's around 150gph

- PowerHead? or Sump Pump? I have used hagen aquaclear powerheads on my saltwater tanks for years 24/7 without a problem. I just purchased 3 MaxiJet 1200 powerheads and a wave timer to see haw they do, 6 months now 24/7 and so far so good. The longest lasting Sump Pump that I have ever owned is made by Ehime, I've had it for 14 years now and it's still going in one of my tanks. I better cross my fingers on that one.LOL

- Q: My fiance's 2002 Cougar is overheating and we can't seem to diagnose the problem. As soon as she touches the gas pedal, the meter shoots to quot;Hquot;, but when we sit at a red light, it returns to center. I tried googling a few things and I've gotten a few things about the water pump, but I know next to nothing about cars. Where is it so I can look at it and feel dumb about STILL not being able to do anything? =D

- Leave the water pump alone! It sounds to me like your gauge is malfunctioning. Every so often an electrical gauge will fail and give strange readings. It could either be the sensor that reads your coolant temp or the gauge body itself. Your car cannot go from overheating to fine while stationary at a red light. Take it to a shop (that specializes in electrical, they're out there) and tell them the temp gauge is acting wacky. If you INSIST to know the location of your water pump...should be on the passenger side of the car mounted to the engine. It's either driven by an accessory belt or the timing belt, I can't remember at the moment. Here's a trick also. Water pumps are designed to leak when they fail. See if you can find coolant spilling out of anywhere a few ounces at a time. Good luck!

- Q: Assuming that my water pump standard flow is 20m3/h, tolerance value requirements is + 8%, then is not traffic 22m3/h is not qualified?

- Tolerance coefficient is due in the manufacturing process, will, so each pump products are possible shapes and sizes do not conform to the pattern of the situation, and ensure the test results in the value (operating point) when compared, should be allowed to have a certain tolerance. It should be noted that these tolerances are only relevant to the actual pump and do not involve test conditions and measurement uncertainties. If the pump at a certain working point (the same lift) standard (Design) flow of 20m3/h, the actual flow of 22m3/h, indicating that the pump in the design process has unreasonable place, resulting in waste of power. Deviations from the manufacturing process usually have no positive deviation.A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: How to measure the temperature of pump body?

- It's the temperature of the pump motor!In addition to large pumps, water temperature is rarely monitored. Even so, the temperature of the pump body will not be measured.Since the water pump pumping, the leaves, vanes and shells are no temperature rise, the temperature is mainly concentrated in the bearing: small pumps rely on the work medium can play a role in reducing friction heat;Heating large pump mainly in the thrust bearing and guide bearing, if the bearing is lubricated by water cooling water, if there is oil lubricated oil cooling equipment specially, temperature monitoring of bearing large pumps can be installed in the pump thrust bearing temperature sensor to monitor the varnay.

- Q: can i drive my car ,with a blown water pump, 5 miles to a service center?

- Absolutely not. You'll most likely end up blowing the radiator. A great amount of pressure can/will be built up in the radiator and that's not good. I had the water pump go out in my Mazda MPV and didn't know it. I was going up the expressway and just so happened to notice that my temperature gauge was in the red and then I heard a pop and water and steam came shooting up from underneath the hood. You can usually only go about a 1/4 to 1/2 mile with a blown water pump. You'll have to get it towed.

- Q: I think the water pump in my Oceanic BioCube is going up. What is a good brand that would be compatible? It is 29 gallons. Thanks.

- If okorder or just your local pet store and see if you can't buy a pump with a similar/same output.

- Q: will a water pump that has gone out in a car make water come out the radiater

- Yes and no. If it is not pumping water. the water over heat and come out. A blow head gasket will do the same. A bad Thermostat will do the same.

- Q: Would I notice a difference in driving if I changed my timing belt and water pump?

- If your car is overheating then you might need to change your water pump. If the pump is making a bunch of noise, the bearings might be worn out in it too. The timing belt just keeps your overhead cam in time with the crankshaft - you should replace it at the intervals recommended by the manufacturer - especially if your engine is considered an 'interference' engine - meaning that if it jumps time the valves will hit the pistons. You won't notice any difference in performance with either component though. For performance, check your plugs, plug wires, air filter, run some fuel injector cleaner through your gas, and replace the fuel filter. Other performance related issues include - fuel pump failing or reduced compression (due to piston rings being worn out).

- Q: I was recently driving and noticed my heat gauge in the red. I have a 1992 Honda Accord 4 door LX. When I opened the hood what appears to be water was all over the place. Is this the water pump or something else? I want to fix it this weekend so I was hoping for a better understanding of what it might be. I am aware of the labor involved with the water pump and removing the timing belts to get to it. Thanks a bunch in advance!

- it should,nt be water, it should be anti-freeze if it was leaking. if you meant anti-freeze the it don,t have to be the pump. it cold be a busted radiator hose, the radiator or 1 of the heater hoses leaking.

- Q: I want to know the disadvantages of a wind powered water pump and if you have any questions you would ask to someone presenting to you about a wind powered water pump(They should be really hard and smart questions) please include them in your answer.Thanks in advance.

- The disadvantage is that it will not work with no wind. I would ask: 1. expected life 2. maintenance cost 3. capacity (liters/hour) at the mean wind speed on installation site 4. height it can pump the water (so that I can check the possibility of having a reservoir for the no wind period)

Send your message to us

Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords