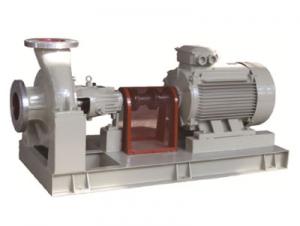

SLZA API610 standard chemical processing pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SLZA series processing pumps are horizontal, singe stage, back pull-out design, they meet 10th version of ANSI/API610-2004 CENTRIFUGAL PUMPS FOR OIL, HEAVY CHEMICAL AND NATUAL GAS INDUSTRY and National standard GB/T3215-2007 of CENTRIFUGAL PUMPS FOR OIL, HEAVY CHEMICAL AND NATUAL GAS INDUSTRY .

Application range

For transferring clean and little contaminated, lower and high temperature, chemical neutral and corrosive liquid.

Mainly for:

Refinery, petrol-chemical industry, coal processing and

lower temperature engineering

Chemical industry, paper-making, pulp, sugar and such

like normal processing industry

Water supply plant and sea water desalination

Heat supply and air-conditioning system

Auxiliary system of power station

Environment protection engineering

Ships and offshore engineering

Operating parameter

Size: 25~400mm

Capacity: up to 2600m³/h

Head: up to 300m

Operating pressure: up to 7.5MPa

Operating temperature: -80 ~+450

Detailes will be referred to drawing of P-T, according to different temperature to select right materials

- Q: my basement flooded and the water came in contact with the wiring on my water pump.Now the pump tries to turn on but shuts off without pumping any water.How do i get my pump pumping water again?

- sounds like not only did it come in contact withe wiring but also with the pump,when your working with electricity you need to be very careful and have the right tools to do the job with. to start this job you need a multi testing meter,this will let you check things like amp,volts,ohms,you know things that comes in contact with the pump and wiring,you didn't say what the voltage is on this pump,so first i'd find out what that is and make sure you have that going to the pump,then if so make sure the pump isn't froze or locked up,next go to the breaker box and locate the breaker for the pump,and test to see how many amps the pump is pulling when turned on.then find out if there is anything restricting the pump from doing its job,it may be something as simple as a run capacitor or even a shorted or burnt wire,but first make sure you have the correct voltage and amperage going to and coming out of the motor,once you get that taken care of you may need to prime the pump in order to get it pumping again

- Q: 1 water pump frequency converter constant pressure water supply wiring diagram

- Light can not be seen in this picture, but also need to see the definition of the terminal on the practical manual, generally speaking, the three terminals are connected to +10V, public and analog signals / multi-function terminals.

- Q: I was wondering if there was a device that can pump and cool water. What I am looking for is essentially an aquarium pump that cools the water as it circulates.

- You okorder /

- Q: I just got a new boat with a diesel engine and I don't understand why there is a coolant tank as well as a water pump? I think the water pump goes to the heat exchanger but what actually cools the motor - how does this stuff work?

- if you do indeed have a heat exchangers, you have two loops at work...the coolant circulates in the engine with its own pump; the tank is for topping up just like in a car. The external water pump....the one connected to the hose to the seacock / through hull...draws in cool sea water, passes that through the heat exchanger where it cools the coolant and then the hot sea water goes out the exhaust. This way you're not circulating hot corrosive sea water through the engine and shortening its life.

- Q: I have a 2001 chevy malibu and need to know how to check if the water pump needs replaced. The engine has been running much hotter than normal and is leaking coolant.

- have a plumer come look at it every so often

- Q: Why should the water inlet of water pump be fitted with reducer?

- Increasing the pipe diameter can reduce the resistance loss along the path and reduce the suction vacuum of the pump! Before the inlet of the pump is a big diameter, when you reach the suction port, and the pump inlet diameter to be consistent, so the use of reducer joints!

- Q: 94 f150,302. my pump is still leaking after doin the job twice. its a new pump, the first time i used the red silicone between pump and plate,both sides of gasket,and the housing on the block. leaked. then did it again with high tack gasket cement and still leaks. i cleaned all metal both times with brake clean before installing. same with thermostat housing,small leak. ive done 100s of pumps over the years,no problems, so please no rude remarks on mechanical ability. what could it be? it leaks up front of the motor above the crossmember where ya cant actually see the leak,its not a freeze plug. bolts are torqued. any ideas ? thanks

- Pay an automotive repair shop to do it. Then it is their problem. Even the best technicians need help once in a while. Yes it costs 3x as much, but no more headache for you.

- Q: I've never had overheating problems before, (although the heating itself never worked great) but today the gauge suddenly spiked while driving at about 50mph. I pulled over and steam was coming off the engine and the cooland tank was bubbling. The coolant was low, but not empty. I put some water in the coolant tank, let the engine cool and drove to a gas station where I got some coolant which I mixed with the water in the coolant tank. That didn't seem to help any. Even after letting the engine cool completely, it spikes after less than five minutes of driving. The radiator and both top and bottom hoses are equally hot. When I tried to start the engine with the radiator cap off, cooland shoots up out the top. The fans are working propely and there is no debris on the front of the radiator. So I'm sort of at a loss. Also, I've had some trouble starting since the problem.

- that its having trouble starting isnt a good sign suggests the gasket or head are done for as for the original issue could be the thermostat, water pump, blockage of some other sort anyway - if its a cheap car time to search out a replacement if its worth some bucks best visit a mechanic

- Q: Had a water pump start leaking, when I replaced it with a new one, it leaked even worse (around the gasket and O rings this time). The process I took...I unbolted everything and removed the water pumpI scrapped everything off with a wire brushI coated both sides of the gasket with red gasket siliconI mounted the new one and bolted it down tightening in a cross pattern(kinda difficult to get everything lined up)It leaked real bad the first time so I loosened the bolts and played with the top rubber seal to make it seat better.It leaked a little less the second time... but still WAY too much.I completely removed it the third time and (totally distroying the gasket) gooped it up with gasket sealer again, along with the O rings and tried again... leaked worse.Considering options... go with a white or black high heat siliconPossibly just using the sealer with NO gasketGooping the HECK out of it with JB-weld and pray!Suggestions?Know what I did wrong here?

- Two questions 1) Did you buy a new gasket? 2) Did you let the sealant set long enough? If you answered yes to both of these than the only thing left is to make sure you have the right type of sealant. Is it the waterproof stuff for waterpumps? You mentioned the stuff was red, it's been a couple of years since I changed a waterpump but I believe it was the BLUE stuff that I needed. But I could be wrong. Take it apart. Make sure it's clean (you can use a wire brush but I find a paint scraper works better) and apply the new gasket to the new water pump then but the whole thing back on the engine. Star pattern tightening the bolts. Test it without putting the clutch fan (I think this still has one) back on just to see if it's leaking. Hope that helps.

- Q: 55KW motor driven lift 70M, the displacement of 180 cubic meters per hour of water pump, the configuration should be no problem, but after the start of the current to 170A (rated 100A), off a small valve to the current export half to reach the rated current. Why current will close a small valve instead of small? Will close a small valve will not affect traffic flow can be? To the 180 party?

- 170A has shown that the motor is overloaded; the head 70M; the displacement of 180 cubic meters; the approximate power is 42Kw (efficiency is higher). At this point, the current of the corresponding motor should be approximately 86A;The power of water pump is related to the quantity of water transported. The water pump is a passive energy conversion device, and it has no regulating ability. It depends entirely on the intersection of its pipeline characteristics and its own characteristics,No, your situation is the pump and pipeline characteristic, the pump head is higher than the resistance of pipeline, so that the water flow movement (increase too large). Pump power becomes largerShut down the water pump, the valve will certainly reduce the amount of water, as for whether to reach 180, you can see the pressure gauge to show the pump lift to determine the pressure of less than 70 meters, the flow of more than 180

Send your message to us

SLZA API610 standard chemical processing pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords