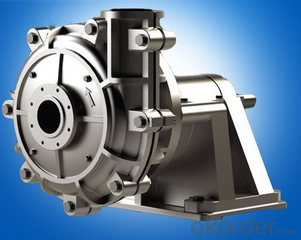

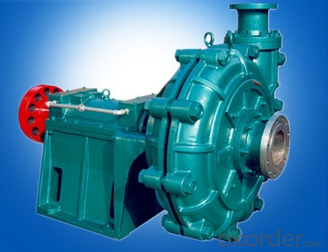

Rubber Anti-wear Slurry Centrifugal pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

Industrial centrifugal ah slurry pump

Cantilevered, horizontal, centrifugal,single stage slurry pump

2. Application

the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3. Features

Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

Wear resistant and anti-abrasion wet parts: The wet parts can be made of hard metal (24-28% Chrome alloy)or pressure molded rubber.They are completely interchangeable with each other.More materials are also available.

Easily replaceable liners: Liners are bolted to the casing.

Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

High efficiency and high head design are also available.

Centrifugal seal,mechanical seal and packing seal are available.

4. Other Pictures

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

- Q: What is LG water pump?

- LG pump LG refers to the name of the water pump brand, not on behalf of practical significance.LG pump is a high-rise building feed pump.1, LG, LG-B type of high-rise building water supply pump is a vertical multistage type structure, bolt the inlet section, the middle section of the water pump are fixed together, each containing a impeller and the guide vanes, the axial force of the hydraulic balance, the residual axial force by one or a pair of ball bearing;2, the shaft seal adopts special design mechanical seal, so when dismantling mechanical seal, do not need to remove the motor, the middle casing coupling can be removed from the seal, it has the advantages of replacement and convenient maintenance;3, pump transmission is through the shell coupling, vertical motor drive, from the motor side to see, the pump clockwise rotation;4, the suction inlet of the pump is below, the water outlet is above, and its relative position can be chosen according to the user's requirements, 0 degrees, 90 degrees, 180 degrees, 270 degrees for assembly, factory. General pump 180 degrees factory.5, assembly without adjustment, easy disassembly;6, the motor can be equipped with standard Y series of ordinary models.

- Q: When replacing the water pump in a 2007 Dodge Grand Caravan. Old one is loose, I'm about to lower the engine a little to get the water pump out. Before putting the new one on, do I have to do anything with the timing belt/chain?

- Depends on the engine size . If the pump is driven by the timing belt then yes , if the pump is driven by the serpentine belt then no .

- Q: I want to put a water pump on a horse trough with the pump on the outside of the fence. There is a hose attachement at the bottom of the trough for the intake. I want to have the outake hook back to fall into the top of the water, reducing algae and eliminating mosquito larvae. I have never used a pump before. Need advice on type, size, etc. Thanks!

- A 12 volt water feature pump from a garden center would do the job. Four litres a minute with a shower head on the end going into the trough should give the aeration you need. The head off a plastic watering can would also do.

- Q: I have to replace the hot water recirculating pump in my house. It is made in Hungary and the Manufacturer's letters look almost Russian. The only words in English are the spec's (amp draw, voltage, etc.) This house was built in 1998 and the plumber's no longer in business. It looks like it just threads onto a quot;capbut I don't want to start using pipe wrenches and just mangle it (it's very difficult to get to also). Any help would be appreciated. Thanks, Mike

- particular you are able to. in certainty there's a recirculating equipment called a Polaris water heater which could furnish warm water for all your place carry desires and warmth your place too. the cost of operationg a Polaris equipment is extra cost-effective than an on call for warm water heater.

- Q: I have a 94 Mazda b2300 it was working great last week then all the sudden it started making a knocking sound and started to overheat! Its still drivable but it overheats if i go far! A friend told me it can be the Water Pump so i put a new one, I was told it can be the Thermostat so i had a new one put in. It worked for awhile but began overheating again. My truck is my livelihood so its important i get it fixed! I cant afford a mechanic but just asking to see if anyone knows what it could possibly be? It catches good and the engine sounds strong but it keeps overheating!

- Your friends and Kirk don't seem to be working for you. The knocking sound has me concerned and I'm not sure how it plays into the overheating. First the antifreeze level? After the water pump and thermostat you should have bled the air out of the system. Don't think you can fill the reservoir tank and it will be okay. Take the cap off the radiator to confirm it is full. Next is the fan. If it is electric you need to make sure it is working if it is belt driven you need to grab the blade and give it a push, it should not spin free and should only go about one blade past where you pushed it. Engine off for that one please. Next the radiator it self. Make sure the fins and not blocked and air can move through them.

- Q: i want to hook a pressure booster pump to a well pump so i can have some pressure out of the well, is this doable?thanks!

- The okorder The way I see this is the booster system delivers approx. 45 psi in the water line (inside the home) and uses a check valve to hold that pressure. You turn the faucets on and the system's sensor detects the drop and kicks back in.

- Q: Why should the pump fill the air before running? What's the reason why the water doesn't go up?

- First of all, why should exhaust air, pump suction principle is the rotation of the impeller, pump water inside the throw out, and then let the inlet pipe into a vacuum. Then, under the influence of atmospheric pressure, the water pressure is pumped into the pump. Therefore, if the water is not filled, the sealing of the pump is impossible to pump the air inside the evacuation of high vacuum. In other words, do not fill the water, you can not smoke water. You can hear the noise in the pump when the water bubbles under the bottom vacuumThe water doesn't go up because it doesn't have enough vacuum!The reason 1 is because there is no water filling,2, because your pump and water vertical height higher than the pump itself suction stroke.3., the pipeline resistance is too large (including the pipe diameter is too small, elbow and so on)

- Q: We have 2 1995 E320's that are heating up way too high when running. One has been diagnosed at the repair shop for a malfunctioning fan clutch. They also said that as the car was running hot the water pump and thermostat should also be replaced (??) The water pump is 5.5 hours of labor and I cannot afford it right now. I was wondering how hard to replace it myself. Thanks

- 95 Mercedes E320

- Q: Even when all water is shut off in the camper, my water pump keeps running. Even when the tank is completely empty. Does anyone know what is causing this?

- I might be miss-understanding your question. If you have no water in the tank then the pump will run all the time because you won't build enough pressure in the system to shut it off. There should be a switch to turn it off manually. If your system has water in it and pump still won't shut off then it could be several different things: 1. Pump is bad and leaking internally... do you have good pressure at the faucet? 2. There should be a pressure cut-out switch somewhere near the pump. This switch should shutoff the pump when the ideal pressure is reached and prevent the pump from over pressurizing the system. Make sure it is not stuck closed. (May have to remove to test) Check for continuity across the terminals with pressure with the pressure on and off. If it doesn't' change... replace. 3. You could have a leak somewhere in the system not allowing the system to build pressure. 4. There may be a pressure relief valve somewhere in the system that is stuck open and dumping your pressure back into the suction side of the pump. Good Luck!

- Q: I need a new timing belt and I'm getting that done soon, but my mechanic says that water pumps are usually replaced along with the timing belt at the same time. Does it really need replaced?

- not dont have to replace unless it was leaking it but it is off now and wouldnt cost anything in labor since hes taking it oof so get to what he need to fix but no it dont have to be replace til it leaks

Send your message to us

Rubber Anti-wear Slurry Centrifugal pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords