PVC Roofing and Waterproofing Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

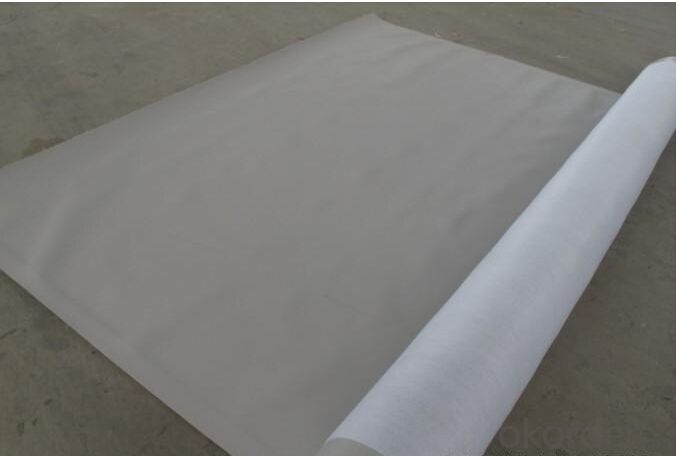

Introduction of PVC Waterproof Membrane

PVC waterproofing roofing membrane are based upon Polyvinyl Chloride Resin with other additives to provide flexibility and stability. It gives a good performance of anti-oxidant, absorbent of ultraviolet light, plasticizer, anti-UV agent, anti-aging with other additives to provide flexibility and stability. It gives a good performance of anti-oxidant, absorbent of ultraviolet light, plasticizer and plastic filling agent.

It is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti-aging agent, and stabilizer and other processing aids through extrusion and molding.

As the highly recommended product by the Ministry of Consturction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to weathering and root penetration and long service life.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for bridges?

- Yes, a waterproofing membrane can be used for bridges. Waterproofing membranes are commonly used in bridge construction to protect the bridge deck and structural elements from water penetration and moisture damage. The membrane forms a barrier against water and prevents corrosion of reinforcing steel, extending the lifespan of the bridge.

- Q: What is the preferred level of waterproofing?

- 2, roof 2 waterproof: Applications: important buildings and high-rise buildings; Waterproof layer of reasonable use of life: 15 years; Waterproof layer selection of materials: should choose high polymer modified asphalt waterproofing membrane, synthetic polymer waterproofing membrane, metal sheet, synthetic polymer waterproof coating, high polymer modified asphalt waterproof coating, fine stone concrete, flat tile, linoleum Tile and other materials; Fortification requirements: two waterproof fortification.

- Q: Are waterproofing membranes resistant to wind-driven rain?

- Yes, waterproofing membranes are designed to be resistant to wind-driven rain. They are typically made from durable materials that can withstand the impact of rain and are installed to provide a protective barrier against water penetration.

- Q: How does a waterproofing membrane handle exposure to chemicals?

- A waterproofing membrane is designed to handle exposure to chemicals by providing a protective barrier that prevents them from penetrating through the membrane. It is typically resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils. This ensures that the membrane remains intact and effective in preventing water ingress, even in environments where chemical exposure is common.

- Q: Does a waterproofing membrane affect the appearance or finish of a surface?

- Yes, a waterproofing membrane can affect the appearance or finish of a surface. When applied, the membrane forms a barrier that prevents water or moisture from penetrating the surface. Depending on the type of membrane used, it can create a visible layer on top of the surface, altering its appearance. For example, a clear liquid membrane may leave a glossy finish, while a sheet membrane may create a textured or patterned surface. Additionally, some membranes may change the color or darken the surface slightly. Therefore, it is important to consider the aesthetic implications of a waterproofing membrane before application, especially if maintaining the original appearance of the surface is a priority.

- Q: Can a waterproofing membrane be applied on top of insulation materials?

- Applying a waterproofing membrane on top of insulation materials is possible. In fact, it is often advisable to install a waterproofing membrane over insulation materials to provide an extra layer of safeguard against moisture infiltration. This is particularly crucial in areas vulnerable to water damage, such as basements or places prone to heavy rainfall. The waterproofing membrane helps prevent water from seeping into the insulation, which could cause harm or reduce its efficiency. Moreover, the membrane acts as a barrier, inhibiting water vapor from penetrating the insulation and potentially causing condensation or mold growth. However, it is vital to ensure proper installation of the insulation materials and the presence of any required air gaps or drainage systems to avoid water from getting trapped between the membrane and the insulation.

- Q: Can a waterproofing membrane be used in residential construction?

- Yes, a waterproofing membrane can be used in residential construction. It is commonly used in areas such as basements, bathrooms, and roofs to prevent water infiltration and protect the structure from moisture damage.

- Q: How does a waterproofing membrane handle construction joints?

- A waterproofing membrane is designed to provide a protective barrier against water penetration in construction applications. When it comes to construction joints, which are commonly found in concrete structures, the membrane is specifically engineered to handle these areas. During the construction process, joints are created to allow for movement between different sections of the structure. These joints can be vulnerable points where water can potentially infiltrate. To address this concern, waterproofing membranes are installed to ensure that these joints remain watertight. There are different methods used to handle construction joints with waterproofing membranes. One common approach is to apply the membrane directly over the joint, extending it beyond the joint edges. This creates a continuous waterproof layer that covers both the joint and the adjoining areas. Another technique involves the use of specially designed joint tapes or strips that are embedded within the membrane. These tapes or strips are typically made of materials like rubber or PVC and are placed directly over the joint before the membrane is applied. They serve as an additional layer of protection, enhancing the waterproofing performance of the membrane at the joint. In addition to these methods, there are also specialized waterproofing systems available that include pre-formed joint sealants. These sealants are designed to fit snugly into the joint, providing a tight seal against water intrusion. The membrane is then installed over the joint, ensuring comprehensive waterproofing coverage. Overall, a waterproofing membrane is specifically designed to handle construction joints by providing a durable and effective barrier against water penetration. Whether through extending the membrane over the joint, using joint tapes or strips, or incorporating pre-formed joint sealants, these membranes ensure that construction joints remain watertight, protecting the structure from potential water damage.

- Q: Does a waterproofing membrane require any specific surface preparation for tile installations?

- Specific surface preparation is required for tile installations when using a waterproofing membrane. The longevity of the tile installation and the success of the waterproofing membrane depend on proper surface preparation. Before applying a waterproofing membrane, it is vital to confirm that the surface is clean, dry, and free from contaminants such as dust, debris, oil, grease, or any loose or crumbling materials. Thoroughly cleaning the surface is necessary and removing any existing tile, adhesive, or grout may be required. In addition to cleanliness, achieving a smooth and even surface is important. Any uneven areas or imperfections should be leveled and patched with an appropriate patching compound. This step prevents water from pooling or seeping beneath the waterproofing membrane, which could cause issues like leaks, mold growth, or damage to the tile installation. Moreover, ensuring the surface is structurally solid and stable is essential. Addressing and repairing any cracks, weak areas, or signs of instability before installing the waterproofing membrane is necessary. This establishes a sturdy foundation for the tile installation and prevents future problems. To summarize, proper surface preparation is critical for the success of both the waterproofing membrane and the tile installation. It guarantees a clean, smooth, and stable surface, which is essential for the membrane to adhere effectively and provide reliable waterproofing. Following the manufacturer's guidelines and seeking professional advice if necessary will help ensure correct surface preparation for a durable and dependable tile installation.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Yes, a waterproofing membrane can certainly be used in stadiums or sports complexes. In fact, it is highly recommended to use waterproofing solutions in these types of structures to protect them from water damage and leakage. A waterproofing membrane acts as a barrier, preventing water from seeping into the concrete or other materials used in the construction of the stadium or sports complex. This is particularly important in areas where heavy rainfall or high humidity is common. By applying a waterproofing membrane to the roofs, walls, and foundations of these structures, it helps to ensure the integrity and longevity of the building, while also providing a comfortable and safe environment for athletes and spectators alike. Waterproofing membranes are designed to withstand the stresses and movements associated with the building, making them an ideal solution for stadiums and sports complexes. Additionally, modern waterproofing membranes are available in various forms, such as liquid-applied or sheet membranes, allowing for flexibility in application and compatibility with different construction materials.

Send your message to us

PVC Roofing and Waterproofing Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords