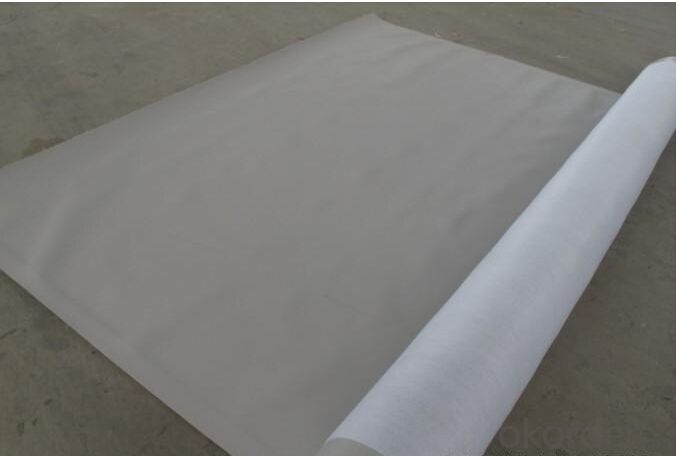

PVC Roofing Waterproof Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 350000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane. The raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Application of PVC Waterproof Membrane

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subway.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for laboratories or research centers?

- Yes, a waterproofing membrane can be used for laboratories or research centers. Waterproofing membranes are designed to provide a barrier against water and moisture, preventing water infiltration and potential damage to the structure. In laboratories or research centers, where sensitive equipment, valuable specimens, and important data are present, it is crucial to maintain a controlled environment free from moisture. A waterproofing membrane can be applied to various surfaces such as floors, walls, or roofs to ensure that no water leaks occur. This helps to protect equipment, prevent potential hazards, and maintain a safe working environment. Additionally, waterproofing membranes can also assist in the prevention of mold growth, which is important for maintaining air quality in laboratories and research centers. Overall, the use of a waterproofing membrane is a wise choice to safeguard the integrity and functionality of laboratories and research centers.

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- Yes, a waterproofing membrane is suitable for use in areas with high groundwater levels. A waterproofing membrane is designed to prevent water penetration and can be effective in creating a barrier against groundwater. These membranes are typically made from materials such as bitumen, PVC, or EPDM, which are highly resistant to water and can withstand high hydrostatic pressure. They are specifically engineered to provide a watertight seal, preventing water from seeping into structures or underground spaces. Therefore, a waterproofing membrane is an ideal solution for areas with high groundwater levels, as it can effectively protect against water intrusion and potential damage to buildings or infrastructure.

- Q: Can a waterproofing membrane be used for a swimming pool liner installation?

- Yes, a waterproofing membrane can be used for a swimming pool liner installation. Waterproofing membranes are specifically designed to create a barrier against water penetration, making them an ideal choice for lining swimming pools. These membranes are typically made from durable materials such as PVC or EPDM, which are resistant to chemicals and UV rays. They can effectively prevent water from seeping through the pool structure and protect it from damage caused by moisture. Additionally, waterproofing membranes are flexible and can be easily customized to fit any pool shape or size, providing a seamless and watertight installation.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Yes, a waterproofing membrane can be used for residential buildings or homes. It is commonly used in basements, bathrooms, and other areas prone to water damage to prevent moisture infiltration and protect the structure from potential water leaks or flooding.

- Q: Are waterproofing membranes suitable for historical buildings?

- Yes, waterproofing membranes can be suitable for historical buildings. These membranes provide an effective solution for preventing water penetration and damage to the structure, helping to preserve the integrity and longevity of the building. However, it is essential to consider the specific requirements and characteristics of the historical building and select an appropriate membrane that is compatible with its materials and architectural features. Additionally, any waterproofing work should be done with sensitivity and care to ensure it does not compromise the historical value or aesthetics of the building.

- Q: What are the potential drawbacks or limitations of using a waterproofing membrane?

- One potential drawback of using a waterproofing membrane is the potential for improper installation. If the membrane is not installed correctly, it can lead to leaks and water damage. It requires a certain level of expertise and attention to detail to ensure that the membrane is properly applied and sealed. Another limitation is that waterproofing membranes can be relatively expensive compared to other waterproofing methods. The cost of purchasing and installing the membrane, as well as any necessary maintenance or repairs, can add up quickly. This may make it less feasible for some budget-conscious individuals or organizations. Additionally, waterproofing membranes are not a one-size-fits-all solution. Different types of membranes are suitable for different applications, and it is important to choose the right one for the specific requirements of the project. This requires knowledge and understanding of the various options available, which can be a challenge for those without experience in the field. Another potential drawback is the limited lifespan of waterproofing membranes. Over time, they can deteriorate or become damaged, which may require replacement or repairs. This can be costly and time-consuming, especially if the membrane needs to be removed and replaced in order to fix the issue. Lastly, waterproofing membranes are primarily used for below-grade applications or on horizontal surfaces such as roofs or decks. They may not be as effective for vertical surfaces such as walls or in areas where there is significant movement or stress, such as expansion joints. In these cases, alternative waterproofing methods may be more suitable. In summary, while waterproofing membranes offer excellent protection against water intrusion, they also come with potential drawbacks and limitations such as improper installation, high cost, need for expertise in selection, limited lifespan, and limitations in application. It is important to weigh these factors and consider alternative options before deciding on a waterproofing solution.

- Q: Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- The advantages of the present invention Is: 1. elongation of permanent deformation is good, after stretching the rebound rate is small, no internal stress, can be fully adapted to the external factors caused by the deformation, there is no accelerated aging after the problem, so the service life can be improved 2-3 Times more than. 2. elongation, up to 1000%. 3. Natural vulcanization of a long time, can reach more than 10 years. 4. Good resistance to low temperature performance. 5. Bonding performance is good. 6. Production costs and operating costs are lower than other existing products.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing products?

- Indeed, when it comes to waterproofing, it is customary to employ various products in conjunction with a waterproofing membrane. This practice aims to offer heightened safeguarding against water-related harm. For instance, one may opt to utilize a waterproofing membrane as the primary layer of protection, which can then be complemented by additional products like sealants, coatings, or drainage systems to enhance durability and performance. By combining these products, a more resilient and all-encompassing waterproofing system can be achieved, effectively shielding against water infiltration and averting any potential leakage or moisture-related complications.

Send your message to us

PVC Roofing Waterproof Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 350000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords