High Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs, basements, toilets etc; and the waterproofing of bridges, parking area, tunnels, reservoir etc.

Characteristic of Self-adhesive Waterproofing Membrane:

1)Self-adhesion without bonding agent,torching.

2)Good rubber elasticity,and elongation

3)Excellent adhension bond

4)Good self-coalescence

5)Safe application,no pullution

6)Excellent waterproof and high strength

7)Available for wet ground

8)Corrosion resistance and ageing-resistance

Description of Self-adhesive Waterproofing Membrane:

Description Details | Width | Length | Thickness | Weight | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials (PE) | 1m | 10m | 2mm | 28kg/roll | |

| 1m | 10m | 3mm | 41kg/roll | |

| 1m | 8m | 4mm | 45kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with mineral granules(M)

| 1m | 10m | 3mm | 45kg/roll | |

| 1m | 8m | 4mm | 47kg/roll | |

| 1m | 8m | 5mm | 57kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with aluminum foil(Al) | 1m | 10m | 2mm | 29kg/roll | |

| 1m | 10m | 3mm | 42kg/roll | |

| 1m | 8m | 4mm | 46kg/roll | |

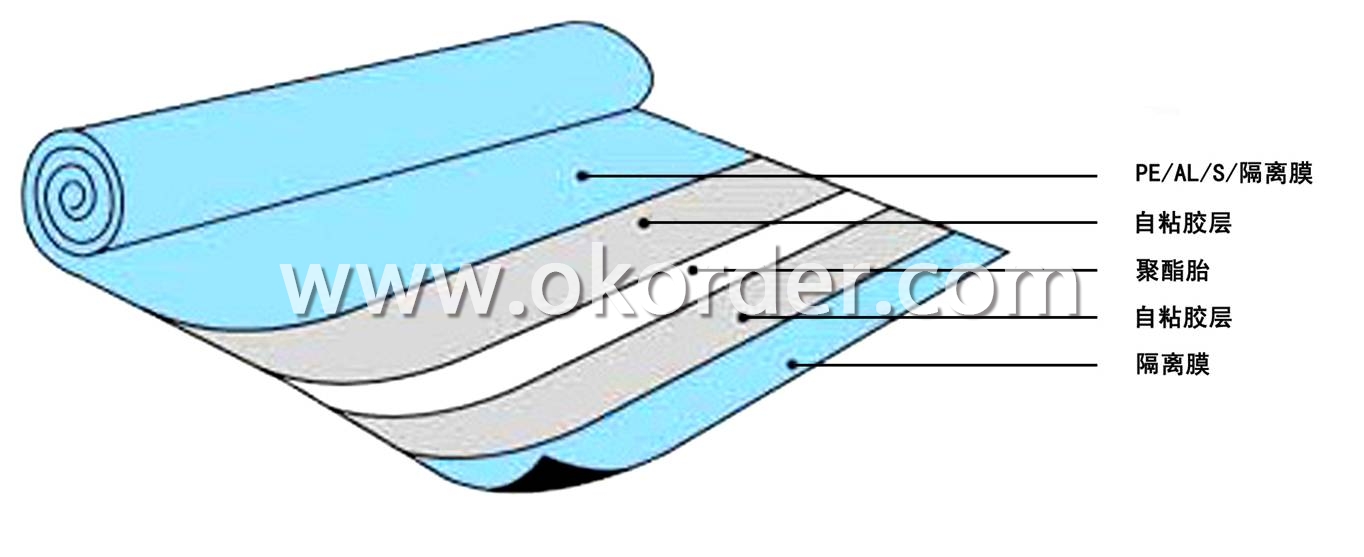

Pictures of Self-adhesive Waterproofing Membrane:

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are designed to be resistant to frost damage. They are typically made from durable materials that can withstand freezing temperatures without cracking or deteriorating.

- Q: Can a waterproofing membrane be used in coastal areas?

- Indeed, the utilization of a waterproofing membrane is viable in coastal regions. Given their susceptibility to copious amounts of moisture and water exposure, it becomes imperative to implement efficient waterproofing measures. By appropriately installing and upkeeping a waterproofing membrane, one can establish a protective barrier, effectively thwarting water infiltration and averting structural damage while ensuring their longevity. Nevertheless, it is crucial to opt for a membrane specifically tailored for coastal environments as they exhibit heightened resistance to saltwater and possess superior durability to withstand the harsh coastal conditions. Moreover, routine inspection and maintenance are imperative to guarantee the continued efficacy of the waterproofing membrane in coastal areas.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. It is a common practice to apply waterproofing membranes on masonry surfaces to prevent water penetration and protect the structure from moisture damage.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Plant rooms often house machinery and equipment that require protection from water and moisture. Using a waterproofing membrane can help prevent water damage to the plant room and the equipment inside. It creates a protective barrier that keeps water from penetrating the walls, floors, and ceilings of the plant room. This can be especially important in areas where there is a higher risk of water leaks or condensation. Waterproofing membranes are designed to withstand various environmental conditions and can provide long-lasting protection for plant rooms.

- Q: Can a waterproofing membrane enhance the durability or lifespan of a structure?

- Certainly, the durability and lifespan of a structure can be significantly enhanced with the use of a waterproofing membrane. This type of membrane acts as a protective layer, applied to the exterior of structures like buildings or bridges, with the purpose of preventing water penetration. Essentially, it functions as a barrier that stops water from seeping into the structure and causing harm. Water is a common and destructive element that can negatively impact the longevity of any structure. When water infiltrates a building or any other type of structure, it can lead to a variety of problems, including mold growth, deterioration of building materials, corrosion of metal reinforcements, and even structural instability. However, by implementing a waterproofing membrane, these risks can be significantly reduced or even eliminated altogether. The installation of a waterproofing membrane not only prevents water from entering, but it also safeguards the structure against other environmental factors such as moisture, humidity, and freeze-thaw cycles. Acting as a shield, it ensures that the building materials remain intact and reduces the likelihood of cracks, leaks, and other forms of structural damage. By enhancing a structure's durability, a waterproofing membrane can effectively prolong its lifespan. Considered a long-term investment, it helps prevent costly repairs and maintenance caused by water-related issues. By keeping the structure dry and protected, it adds years or even decades to its lifespan, ultimately saving both time and money in the long run. In conclusion, a waterproofing membrane is an essential component for maintaining the durability and lifespan of any structure. By preventing water infiltration and protecting the building materials from damage, it ensures the longevity of the structure and provides peace of mind to its owners and occupants.

- Q: Can waterproofing membranes be used on plant rooms?

- Yes, waterproofing membranes can be used on plant rooms. Waterproofing membranes are often used in areas where water resistance is necessary, such as basements, roofs, and plant rooms. Plant rooms typically house various mechanical and electrical equipment, and using waterproofing membranes can help protect these sensitive components from water damage.

- Q: Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are specifically designed to withstand and resist water penetration, making them suitable for areas with high water pressure. These membranes are typically made from materials such as rubber, PVC, or bitumen, which are highly durable and have excellent waterproofing properties. Additionally, waterproofing membranes can be reinforced with additional layers or fabrics to enhance their strength and resistance to water pressure. However, it is crucial to ensure that the waterproofing membrane is properly installed and meets the specific requirements of the area to ensure its effectiveness in high water pressure situations. Professional consultation and adherence to manufacturer guidelines are recommended to ensure the membrane's performance in such conditions.

- Q: Can a waterproofing membrane be used in new construction?

- A waterproofing membrane is capable of being utilized in new construction. In fact, it is frequently advised to incorporate a waterproofing membrane during the construction phase to furnish an extra layer of safeguard against water harm. Typically, waterproofing membranes are administered to the external foundation walls and basement floors to obstruct water infiltration and construct a barrier against moisture. This can effectively avert predicaments like leaks, mold, and structural damage in the long run. Furthermore, waterproofing membranes can also be employed in other areas of a new construction project, such as roofs, balconies, and bathrooms, to guarantee long-lasting waterproofing protection. On the whole, the utilization of a waterproofing membrane in new construction can contribute to the extension of the building's lifespan and instill peace of mind for its occupants.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. It is commonly used to protect against water damage and prevent leaks in areas where water is present, such as laundry rooms, bathrooms, and kitchens.

- Q: What are the advantages and disadvantages of waterproofing membrane?

- There are many types of waterproofing membrane, mostly flexible waterproofing membrane. Such as: SBS coil, PVC, EVA, ECB The advantages of the coil is simple operation, do not need any valuable equipment, the basic is the torch, hot melt welding machine, are not expensive, the shortcomings of the base is a higher demand, it is easy to be damaged, resulting in structural leakage.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Europe; North America; Africa; Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6- 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100000 Square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

High Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords