EPDM Roof Waterproof Membrane with 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

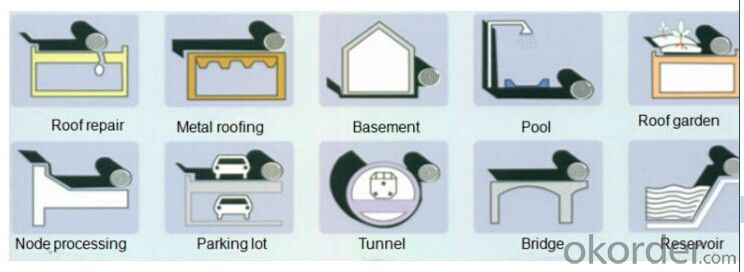

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM roofs are typically made from a rubber material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, extending the lifespan of the roof.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Certainly, roofs with skylights can benefit from the use of a waterproofing membrane. It is strongly advised to employ a waterproofing membrane around skylights in order to prevent water infiltration or leakage. Skylights have the potential to become weak points in a roof system, as they form openings that can let water seep through if not adequately sealed. The application of a waterproofing membrane around the skylights serves to establish a watertight barrier that safeguards the roof from any potential leaks. Furthermore, a waterproofing membrane also offers added protection against external factors such as UV rays and changes in temperature, thereby extending the lifespan of both the skylights and the roof itself.

- Q: Can a waterproofing membrane be used for a commercial building?

- Indeed, a commercial building can utilize a waterproofing membrane. Specifically engineered to safeguard structures against water damage, these membranes find wide application in commercial settings, encompassing rooftops, basements, and foundation walls. Serving as a protective barrier, the membrane effectively prevents water infiltration, safeguarding against leaks, moisture accumulation, and the growth of mold. Moreover, waterproofing membranes exhibit durability, enabling them to withstand inclement weather conditions, rendering them suitable for commercial buildings exposed to heavy rainfall or extreme temperatures. Ultimately, the incorporation of a waterproofing membrane within a commercial building proves highly effective in preserving long-term structural integrity and averting costly water-related impairments.

- Q: Can a waterproofing membrane be used on bridges?

- Bridges can indeed benefit from the application of a waterproofing membrane. It is quite common to utilize waterproofing membranes during bridge construction and rehabilitation projects in order to safeguard the bridge deck against water infiltration. These membranes are specifically designed to create a seamless and robust barrier, effectively preventing water from reaching the underlying bridge structure. By implementing a waterproofing membrane on the bridge deck, it significantly prolongs the lifespan of the bridge by minimizing moisture-induced damage and thwarting the corrosion of reinforcement steel. Moreover, these membranes also aid in diminishing the potential for freeze-thaw damage, cracking, and deterioration of the bridge deck. All in all, incorporating a waterproofing membrane on bridges is an efficacious approach to ensure the enduring durability and structural integrity of the bridge.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM roofs are typically made from a rubber material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, extending the lifespan of the roof.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can definitely be used for stadiums or arenas. In fact, it is highly recommended to use waterproofing membranes in these large-scale structures to protect them from water damage and leaks. Stadiums and arenas are often exposed to various weather conditions, including heavy rain and snow, which can potentially cause water infiltration into the structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the building envelope and causing damage to the structural components, such as concrete or steel. It helps to maintain the integrity of the structure and prolong its lifespan. Additionally, waterproofing membranes can also provide protection against other forms of moisture, such as condensation and humidity, which can lead to mold growth and deterioration of materials. Therefore, using a waterproofing membrane is a crucial step in ensuring the durability and longevity of stadiums and arenas.

- Q: Can a waterproofing membrane be used on cement board surfaces?

- Yes, a waterproofing membrane can be used on cement board surfaces. Cement board is a commonly used material in construction, particularly in areas prone to moisture such as bathrooms and kitchens. While cement board itself is water-resistant, it is not completely waterproof. Therefore, using a waterproofing membrane can provide an additional layer of protection against water damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the cement board. It is designed to prevent water from penetrating the board and reaching the underlying structure. This is especially important in areas where water exposure is frequent, such as shower stalls or backsplashes. There are different types of waterproofing membranes available, including liquid-applied membranes and sheet membranes. Liquid-applied membranes are typically applied with a brush or roller, while sheet membranes are rolled onto the surface and adhered using an adhesive or thinset mortar. When applying a waterproofing membrane to a cement board surface, it is important to follow the manufacturer's instructions and ensure proper adhesion. This may involve cleaning and priming the surface beforehand, as well as allowing sufficient drying time between coats. In conclusion, using a waterproofing membrane on cement board surfaces can help protect against water damage and prolong the life of the construction. It is a recommended practice, especially in areas prone to moisture, and can provide added peace of mind for homeowners and contractors alike.

- Q: Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Yes, a waterproofing membrane can be used in food processing or pharmaceutical facilities. Waterproofing membranes are commonly used in these types of facilities to ensure that the surrounding environment remains dry and free from water damage. They create a protective barrier against moisture, preventing leaks and water penetration. This is particularly important in food processing and pharmaceutical facilities where hygiene and cleanliness are crucial. Waterproofing membranes can be applied to various surfaces such as floors, walls, and ceilings, ensuring that all areas are adequately protected. Additionally, these membranes are often made from materials that are resistant to chemicals and bacteria growth, further enhancing their suitability for use in these sensitive environments. Overall, utilizing a waterproofing membrane in food processing or pharmaceutical facilities is an effective way to maintain a dry and safe environment for the production of quality products.

- Q: Can a waterproofing membrane be used on brick block surfaces?

- Brick block surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are widely used to create a barrier against water infiltration and safeguard buildings from moisture damage. When applied correctly, they effectively seal brick block surfaces, safeguarding against water penetration and promoting the structure's longevity and durability. Acting as a protective layer, the membrane prevents water from seeping into the bricks and causing issues like deterioration, cracking, or mold growth. It is crucial to choose a waterproofing membrane specifically designed for brick block surfaces and meticulously follow the manufacturer's instructions for proper application. Moreover, seeking guidance from a professional contractor experienced in waterproofing is highly recommended to ensure optimal outcomes and long-term performance.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Precast copper surfaces can indeed utilize a waterproofing membrane. These membranes possess adaptability and can be utilized across a diverse range of surfaces, including copper. Their primary purpose is to establish a protective barrier that hinders water infiltration and safeguards the underlying structure from moisture-induced harm. With accurate application, a waterproofing membrane can proficiently seal precast copper surfaces, securing enduring defense against water intrusion. Nevertheless, it is vital to verify the compatibility of the membrane with copper and conduct thorough surface preparation to guarantee optimal adhesion and performance.

Send your message to us

EPDM Roof Waterproof Membrane with 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords