PVC Waterproofing Membrane

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20GP m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

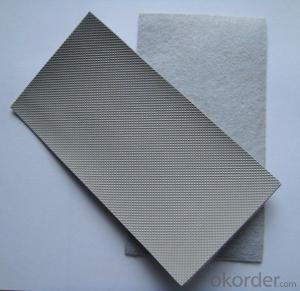

Specification Of Colored PVC Waterproofing Membrane With Good Quality From China

Width: 2m

Thickness: 1.2mm , 1.5mm , 2.0mm

Length: 20m

Features Of Colored PVC Waterproofing Membrane

1 last above 15 years

2 high quality

3 new-type waterproof materials

4 environmental

5 shapely

Application Of Colored PVC Waterproofing Membrane

PVC Waterproof Membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, Bridges,tunnel, water pools, shelter, grain depot, land filling and subway.

Pictures Of Colored PVC Waterproofing Membrane

- Q: How does a waterproofing membrane handle water infiltration from above?

- A waterproofing membrane is designed to prevent water infiltration from above by creating a barrier that is impermeable to water. It is typically made of a durable and flexible material, such as rubber or asphalt, that is specifically engineered to withstand the effects of water exposure. When water falls on the surface above the waterproofing membrane, it acts as a protective layer, preventing the water from seeping through and reaching the underlying structure. The membrane effectively repels the water, ensuring that it does not penetrate into the building or any other protected area. To further enhance its water resistance, the membrane is often installed with overlapping seams and sealed with adhesive or heat to create a continuous and watertight barrier. This helps to prevent any potential gaps or weak points where water could potentially infiltrate. In addition to its impermeability, a waterproofing membrane is also designed to handle water infiltration by providing drainage pathways for any water that may accumulate on its surface. This is achieved through the use of channels or slopes that direct water away from the protected area, ensuring that it is effectively drained and does not accumulate to cause damage. Overall, a waterproofing membrane is specifically engineered to handle water infiltration from above by creating a strong and impenetrable barrier, as well as providing effective drainage mechanisms to prevent water accumulation.

- Q: Can waterproofing membranes be used on concrete pools?

- Yes, waterproofing membranes can be used on concrete pools. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied to various surfaces, including concrete. Concrete pools are susceptible to water leakage over time due to cracks or deterioration, and applying a waterproofing membrane can help prevent these issues. The membrane is typically applied to the pool's interior surface, creating a seamless and watertight seal. It is important to choose a high-quality waterproofing membrane specifically designed for use in swimming pools to ensure long-lasting and effective results.

- Q: Can a waterproofing membrane be used for water features or fountains?

- Indeed, a waterproofing membrane is suitable for water features or fountains. Specifically engineered to obstruct water infiltration, these membranes are an excellent option for water-related purposes. They establish a barricade that confines water within the intended space, warding off any leaks or seepage. Moreover, certain waterproofing membranes possess supplementary attributes, such as UV ray and chemical resistance, which prove advantageous for water features or fountains exposed to sunlight or treated with water treatment chemicals. In summary, the utilization of a waterproofing membrane guarantees the preservation of water features or fountains' impermeability and functionality.

- Q: Can waterproofing membranes be used in basements?

- Basements can indeed benefit from the use of waterproofing membranes. These specialized membranes are designed specifically to act as a barrier against water penetration and are commonly employed in basements to effectively prevent moisture and water seepage. Typically composed of materials like rubber, bitumen, or polyethylene, these membranes are carefully applied to the walls and floors of the basement, creating an impermeable seal that keeps water out. By effectively stopping water from entering the basement, these membranes play a crucial role in safeguarding the foundation, walls, and interior spaces from the damaging effects of water, including mold and other moisture-related problems. Moreover, for comprehensive protection against water infiltration, waterproofing membranes can be utilized in conjunction with other waterproofing techniques like drainage systems and sump pumps.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Yes, a waterproofing membrane can be used for residential swimming pools. These membranes are specifically designed to provide a water-resistant barrier, preventing leakage and protecting the structure of the pool. Waterproofing membranes are commonly used in various applications, including swimming pools, to ensure durability and longevity of the pool.

- Q: How does a waterproofing membrane handle settlement or movement of the substrate?

- A waterproofing membrane is designed to handle settlement or movement of the substrate by providing flexibility and elasticity. It is typically made from materials such as modified bitumen, polyurethane, or acrylic polymers, which have the ability to stretch and contract without compromising the integrity of the membrane. When there is settlement or movement in the substrate, the waterproofing membrane can accommodate these changes by adjusting its shape and size accordingly. This prevents the membrane from cracking or tearing, which could lead to water infiltration and damage to the underlying structure. Additionally, some waterproofing membranes have reinforcing layers or fabrics embedded within them to enhance their strength and resistance to movement. These reinforcement layers help distribute stress and forces caused by settlement or movement, further protecting the membrane from potential damage. Furthermore, proper installation techniques are crucial to ensure the waterproofing membrane can effectively handle settlement or movement. The membrane should be applied in a continuous and seamless manner, using appropriate adhesives or fasteners to secure it to the substrate. This ensures that the membrane can flex and move with the substrate, rather than resisting or restricting its movements. In summary, a waterproofing membrane is designed to accommodate settlement or movement in the substrate by providing flexibility, elasticity, and reinforcement. Proper installation techniques are essential to ensure its effectiveness in handling these movements and maintaining a watertight barrier.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- The advantages of the present invention Is: 1. elongation of permanent deformation is good, after stretching the rebound rate is small, no internal stress, can be fully adapted to the external factors caused by the deformation, there is no accelerated aging after the problem, so the service life can be improved 2-3 Times more than. 2. elongation, up to 1000%. 3. Natural vulcanization of a long time, can reach more than 10 years. 4. Good resistance to low temperature performance. 5. Bonding performance is good. 6. Production costs and operating costs are lower than other existing products.

- Q: Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are designed to withstand and prevent water penetration, making them suitable for use in areas where there is high water pressure. However, it is important to ensure that the membrane chosen is specifically rated and designed to handle the specific water pressure levels in order to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used in industrial facilities or warehouses?

- Yes, a waterproofing membrane can be used in industrial facilities or warehouses. It provides an effective barrier against water penetration, protecting the infrastructure and contents from potential water damage.

- Q: Are waterproofing membranes resistant to algae growth?

- Yes, waterproofing membranes are generally resistant to algae growth. Waterproofing membranes are designed to be highly durable and resistant to various environmental factors, including the growth of algae. They are typically made of materials such as PVC, TPO, or EPDM that are inherently resistant to algae and other microbial growth. Additionally, waterproofing membranes are often treated with anti-algae and anti-fungal agents during their manufacturing process to further enhance their resistance to algae growth. However, it is important to note that while waterproofing membranes are resistant to algae growth, they may still require regular cleaning and maintenance to ensure their long-term performance and prevent any potential build-up of dirt or debris that could potentially provide a favorable environment for algae to grow.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2003 |

| Annual Output Value | Above 50 Million RMB |

| Main Markets | Mid East; Eastern Europe; North America; Southeast Asia |

| Company Certifications | ISO 9001; ISO 14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 10% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 2000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

PVC Waterproofing Membrane

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20GP m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords