The PVC Waterproofing Plastic Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

PVC waterproof membrane, is a kind of macromolecule waterproofing materials with excellent properties, which consists of polyvinyl chloride resin mainly and various dedicated auxiliaries, anti-aging ingredient, produced by advanced equipment and technology.

Application Scope

1.Steel structure roofs, exposed and unexposed concrete roofs, planted roofs.

2.Waterproof projects of basements, metros and tunnels.

Advantagee

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

9.Excellent Quality+ Competitive Cost+ High Productivity +Brand Management +Good Customer Service

10.Strong tensile strength, high elongation, excellent anti-extreme weather property, suitable for exposed projects with long lifetime and good anti-aging property, can be welded firmly, outstanding root penetration resistance, simple and fast construction without pollution, great plasticity and fast treatment with corners and details, etc.

Actually, for all the features listed like above, I’m sure every waterproofing manufacturer would like to use them for the description of their products. But whether surely their products can live up the standards and fill your requirements, it’s a question.

Storage:

Different types or specifications of products should be separated, not mixed.

Keep it dry and ventilated, protected from the sun or rain.

Storage temperature should never be higher than 45 °C. Pile up the membranes flatwise whose stockpile height never exceeds five layers. One layer is guaranteed if it is placed vertically.

Prevent it from inclination or In the process of transportation, it should be lying in case of inclination or lateral pressure. If necessary, cover it with felt-cloth.

Storage time is at least one year from manufacture date on if the product is under normal operation of storage.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

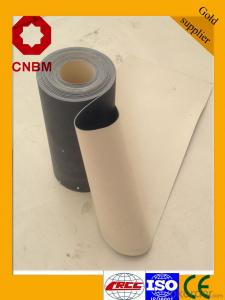

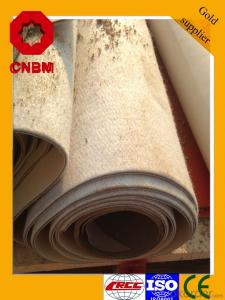

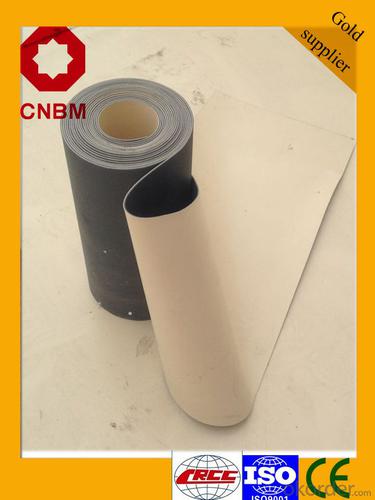

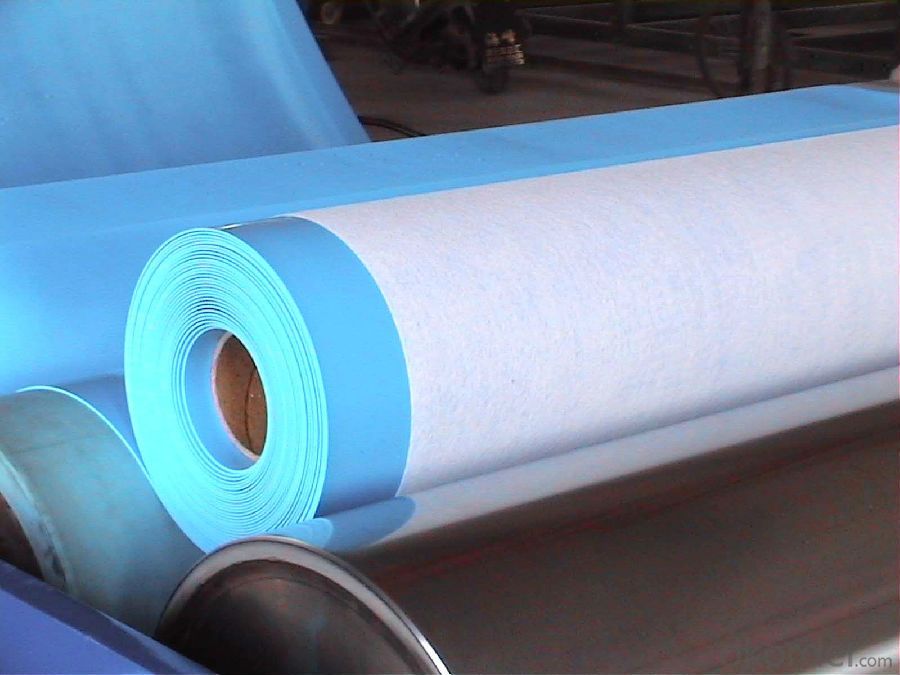

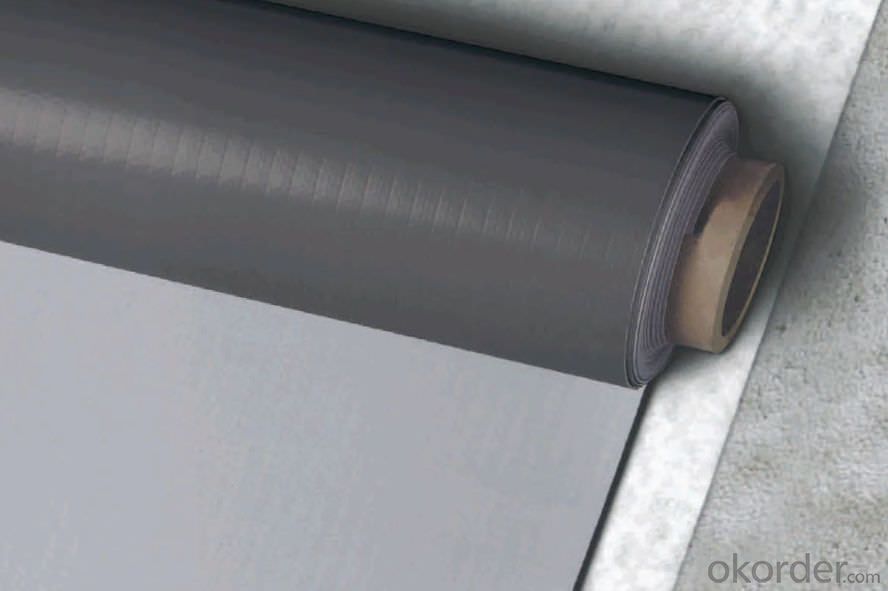

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used for underground storage facilities?

- Yes, a waterproofing membrane can be used for underground storage facilities. Waterproofing membranes are designed to prevent water infiltration, making them an ideal solution for underground structures such as storage facilities. These membranes are typically made from materials such as bitumen, rubber, or polyethylene, which are highly resistant to water penetration. By installing a waterproofing membrane on the walls and floor of an underground storage facility, it helps to create a barrier that prevents water from seeping in, protecting the stored goods from moisture damage. Additionally, waterproofing membranes also help to prevent the growth of mold and mildew, which can be detrimental to the integrity of the structure and the items stored within. Overall, using a waterproofing membrane is a reliable and effective way to ensure the durability and longevity of an underground storage facility.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- When installing a waterproofing membrane, there are various safety precautions to consider. To begin with, it is crucial to ensure that the installation team uses all necessary personal protective equipment (PPE). This may incorporate gloves, safety glasses, and appropriate footwear to prevent injuries or exposure to dangerous substances. Moreover, it is essential to work in a well-ventilated area to avoid inhaling fumes or vapors emitted during the installation process. If working in a confined space, it is necessary to take proper measures to guarantee sufficient ventilation and use suitable respiratory protection if needed. Furthermore, it is vital to adhere to the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This involves understanding any potential hazards linked with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to make sure that the installation area is appropriately prepared before commencing the process. This might entail clearing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and easily accessible first aid kits in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to promptly identify and address any potential safety risks. By adhering to these safety precautions, the installation of a waterproofing membrane can be carried out securely and effectively, minimizing the risk of accidents or injuries.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Yes, a waterproofing membrane can be used on tunnels with fire protection systems. The waterproofing membrane is designed to provide protection against water ingress, while the fire protection system is designed to prevent or minimize the spread of fire. These two systems can be installed and utilized together to ensure the safety and integrity of the tunnel infrastructure.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on precast concrete surfaces. Firstly, the surface must be thoroughly cleaned and free from any dirt, debris, or loose particles. It is also important to ensure that the precast concrete surface is dry before applying the membrane. Additionally, the type of waterproofing membrane used should be compatible with the precast concrete material to ensure proper adhesion. Proper surface preparation, material compatibility, and ensuring a dry surface are key factors to consider when installing a waterproofing membrane on precast concrete surfaces.

- Q: How does a waterproofing membrane adhere to a surface?

- A waterproofing membrane adheres to a surface through a combination of mechanical and chemical bonding. The process typically involves the application of an adhesive or bonding agent to create a strong and durable connection between the membrane and the surface it is being applied to. Mechanical bonding occurs when the membrane is physically held in place by the irregularities and imperfections on the surface. This can be further enhanced through the use of mechanical fasteners such as screws or nails, which help secure the membrane in place. These mechanical bonds provide initial stability and prevent the membrane from shifting or peeling off. Chemical bonding, on the other hand, involves the use of adhesive materials specifically designed for waterproofing applications. These adhesives are typically applied to the surface and the backside of the membrane. Once the membrane is pressed onto the surface, the adhesive chemically reacts with the surface and the membrane, creating a strong bond. The effectiveness of the adhesive is influenced by factors such as surface preparation, environmental conditions, and the type of membrane and adhesive being used. Proper surface preparation, which may involve cleaning, priming, or leveling the surface, ensures that there are no contaminants or unevenness that could compromise the bond. In summary, a waterproofing membrane adheres to a surface through a combination of mechanical and chemical bonding. The mechanical bonds provide initial stability, while the adhesive materials create a durable and long-lasting connection between the membrane and the surface.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Tunnels with water drainage systems can indeed utilize a waterproofing membrane. The purpose of this membrane is to create a protective barrier against water infiltration and effectively prevent any leakage into the tunnel. However, it is crucial to ensure that the waterproofing membrane is compatible with the specific water drainage system in place. The installation of the membrane must be done in a manner that does not hinder or disrupt the functioning of the drainage system. Moreover, it is important to carefully consider the design and installation of the drainage system to ensure efficient water management and avoid any potential complications that may compromise the effectiveness of the waterproofing membrane. By carefully planning and executing the installation, a waterproofing membrane can effectively uphold the overall integrity and durability of tunnels with water drainage systems.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Waterproofing membranes have been specifically developed to resist hydrostatic pressure, which is the pressure exerted by still water. When a building is exposed to ground water, such as in basements or foundations, hydrostatic pressure becomes a significant concern as it can lead to water seeping through walls and floors. To prevent water from penetrating the building structure, waterproofing membranes are engineered to withstand and resist the pressure exerted by water. These membranes are typically made from materials like bitumen, rubberized asphalt, or synthetic polymers, all of which possess excellent water resistance properties. Moreover, the purpose of waterproofing membranes is to create an uninterrupted barrier against water, effectively preventing any potential leaks or seepage. They are applied in multiple layers, ensuring a sturdy and long-lasting barrier that can withstand the high pressure of water. It is crucial to note that the effectiveness of the waterproofing membrane in resisting hydrostatic pressure may vary depending on its type and quality. Hence, it is essential to choose a high-quality membrane and ensure proper installation to maximize its ability to resist hydrostatic pressure.

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

- Q: How does a waterproofing membrane handle movement or settling of the structure?

- A waterproofing membrane is designed to accommodate the movement or settling of a structure in a few different ways. Firstly, a waterproofing membrane is typically flexible and elastomeric, meaning it can stretch and move with the structure without cracking or tearing. This allows it to withstand minor shifts or settlements in the building without compromising its ability to keep water out. Additionally, some waterproofing membranes have built-in reinforcing materials, such as polyester or fiberglass, which provide added strength and durability. These reinforcements help the membrane resist potential damage caused by movement, settling, or even structural vibrations. Furthermore, many waterproofing systems include provisions for expansion joints or movement joints, which are intentionally created gaps or spaces in the structure to allow for natural movement. These joints are then sealed using flexible materials compatible with the waterproofing membrane. This allows the membrane to accommodate the anticipated movement or settling within these joints, preventing leaks or damage to the water barrier. In summary, a waterproofing membrane is designed to handle movement or settling of a structure by being flexible, elastomeric, and capable of stretching without tearing. Additionally, reinforcements and the incorporation of expansion joints further enhance the membrane's ability to accommodate movements and maintain its integrity as a waterproof barrier.

- Q: Can a waterproofing membrane be installed on wood surfaces?

- Yes, a waterproofing membrane can be installed on wood surfaces. Waterproofing membranes are commonly used on various surfaces including wood, concrete, and metal. When applied to wood surfaces, the membrane acts as a protective barrier, preventing water from seeping into the wood and causing damage such as rot, warping, or decay. It is important to choose a waterproofing membrane that is specifically designed for wood, as some products may not be suitable for this surface. Additionally, proper surface preparation and application techniques should be followed to ensure a strong and effective bond between the membrane and the wood surface.

Send your message to us

The PVC Waterproofing Plastic Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords