Mapei Waterproofing Membrane

Mapei Waterproofing Membrane Related Searches

Waterproofing Membrane Philippines Geomembrane Waterproofing Waterproofing Membrane Singapore Waterproof Geomembrane Bentonite Waterproofing Membrane Paintable Waterproof Membrane Redgard Waterproofing Membrane Damp Proof Membrane Red Guard Waterproofing Membrane Waterproof Membrane For Decks Concrete Foundation Waterproofing Membrane Waterproofing Geomembrane Liner Residential Waterproofing Bitumen Roofing Membrane Plastomeric Waterproofing Materials Material Waterproofing Spray Commercial Waterproofing Permeable Geomembrane Waterproofing Wet Areas Waterproof Material Impermeable Geomembranes Waterproof Mdf Panels Waterproof Thermal Blanket Waterproof Sealer Waterproofing Inspection Waterproof Seal Geomembrane Impermeable Waterproof Double Sided Tape Geocomposite Membrane Waterproofing HomesMapei Waterproofing Membrane Supplier & Manufacturer from China

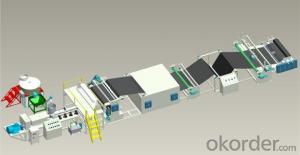

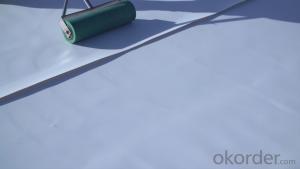

Mapei Waterproofing Membrane is a collection of high-quality products designed to provide effective water protection for various surfaces and structures. These products are engineered with advanced technology to ensure durability and long-lasting performance, making them ideal for both residential and commercial applications. The Mapei Waterproofing Membrane is widely used in various scenarios, such as bathrooms, balconies, swimming pools, and basements, where water resistance is crucial to maintain the integrity and longevity of the building. By offering a comprehensive range of waterproofing solutions, Mapei has established itself as a reliable choice for professionals and homeowners alike.Okorder.com is a reputable wholesale supplier that offers a vast inventory of Mapei Waterproofing Membrane products. As a leading distributor in the construction and building materials industry, Okorder.com is committed to providing customers with top-quality products at competitive prices. With a large selection of Mapei Waterproofing Membrane options available, customers can find the perfect solution for their specific waterproofing needs. By partnering with Okorder.com, customers can enjoy the convenience of a one-stop shopping experience, as well as the peace of mind that comes with knowing they are purchasing from a trusted and reliable source.

Hot Products