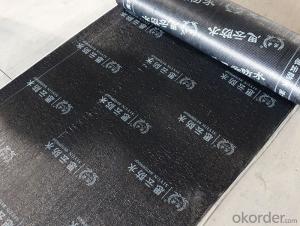

APP modified bitumen waterproof membrane

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Width:1m

Length/roll:7.5m/10m/15m or as your need.

Surface:PE film/Granules/Sand etc.

Thickness:3mm\4mm.

Characteristic:

a) SBS modified bitumen waterproof membrane is specially used as waterproof material in cold area

b) APP is specially suitable for areas of high temperature and of strong sun-shine

SBS/APP Modified Bitumen Waterproof Membrane

c)Good performance in good impermeability ,anti-puncture, anti-broker, anti-resistance, anti-erosion, anti-mildew, anti-weathering

d)Possess good tensile strength, elongation rate and size stability which could be well suited the substrate

distortion and crack

- Q: Is a waterproofing membrane resistant to extreme weather conditions?

- Yes, a waterproofing membrane is designed to be resistant to extreme weather conditions. It provides a protective barrier against heavy rain, snow, and intense sunlight, ensuring that it remains intact and effective in preventing water infiltration and damage to the underlying structure.

- Q: Is a waterproofing membrane compatible with different types of roofing materials?

- Yes, a waterproofing membrane is compatible with different types of roofing materials. A waterproofing membrane is a versatile solution that can be used on various roofing materials such as asphalt shingles, metal roofs, concrete roofs, and even flat roofs. The membrane is designed to provide a barrier against water penetration, regardless of the type of roofing material. It can be applied directly on the surface of the roof or as an underlayment before installing the roofing material. This compatibility ensures that the waterproofing membrane can be used effectively to protect and extend the lifespan of different types of roofs.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. The membrane will provide a protective barrier against water penetration, helping to prevent moisture damage and corrosion on the nickel surface.

- Q: Can a waterproofing membrane be used for a crawl space?

- Yes, a waterproofing membrane can be used for a crawl space. Crawl spaces are susceptible to moisture and water intrusion, which can lead to various issues such as mold growth, structural damage, and unpleasant odors. A waterproofing membrane can act as a barrier to prevent water and moisture from seeping into the crawl space. It is typically installed on the walls and floors of the crawl space, creating a watertight seal. This membrane can effectively prevent water from entering, making it an excellent solution for crawl space waterproofing. Additionally, some waterproofing membranes also have antimicrobial properties, further reducing the risk of mold and mildew growth in the crawl space.

- Q: Can a waterproofing membrane be used for convention centers or exhibition halls?

- Yes, a waterproofing membrane can definitely be used for convention centers or exhibition halls. These types of buildings often have large areas of flat roofs or underground spaces that are prone to water leakage. A waterproofing membrane is a durable and effective solution to prevent water infiltration and protect the structure from potential damage. Convention centers and exhibition halls are subject to heavy foot traffic and can experience high levels of moisture due to the presence of various activities, such as trade shows, concerts, and conferences. Waterproofing membranes provide a seamless and watertight barrier that effectively keeps water out, ensuring the integrity and durability of the building. Additionally, waterproofing membranes can be applied to different types of surfaces, including concrete, metal, and wood, making them suitable for various construction materials commonly used in convention centers and exhibition halls. They can be installed underneath flooring systems, on walls, or as a protective layer on roofs, providing comprehensive water protection for the entire structure. Moreover, waterproofing membranes come in different forms, such as liquid-applied membranes, sheet membranes, or spray-applied coatings. This versatility allows for flexibility in choosing the most appropriate type of membrane based on the specific requirements and conditions of the convention center or exhibition hall. In summary, a waterproofing membrane is an excellent choice for convention centers or exhibition halls due to its ability to prevent water penetration, protect the structure from potential damage, and ensure the longevity of the building.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Indeed, a waterproofing membrane proves effective in chemical or hazardous surroundings. Its purpose is to serve as a barrier against water, moisture, and other liquids, including chemicals and hazardous substances. Typically, these membranes are constructed from chemical-resistant materials like polyurethane, PVC, or modified bitumen. This composition ensures their durability and ability to withstand exposure to various chemicals without harm. Nevertheless, it is vital to choose a waterproofing membrane specifically designed for chemical or hazardous environments to guarantee compliance with necessary requirements and standards. Moreover, proper installation and maintenance play a crucial role in ensuring the long-lasting effectiveness of the waterproofing membrane in such settings.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Yes, a waterproofing membrane can be used for plant rooms and mechanical equipment areas. Plant rooms and mechanical equipment areas often require waterproofing to protect the equipment and surrounding structures from water damage. A waterproofing membrane is a commonly used solution for this purpose. It creates a barrier that prevents water from penetrating into the plant rooms and mechanical equipment areas, ensuring that the equipment remains dry and protected. The waterproofing membrane also helps to prevent moisture-related issues such as mold and mildew growth, which can be detrimental to the operation of the equipment and the overall functionality of the plant room. Overall, using a waterproofing membrane in plant rooms and mechanical equipment areas is a reliable and effective way to ensure the longevity and performance of the equipment and structures.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Yes, a waterproofing membrane can be used on both interior and exterior walls. The membrane helps prevent water penetration, providing protection against moisture for both sides of the wall.

- Q: Can waterproofing membranes be applied on roofs?

- Yes, waterproofing membranes can be applied on roofs. In fact, they are commonly used in the construction industry to provide an extra layer of protection against water infiltration. These membranes are typically made of synthetic materials such as PVC, TPO, or EPDM, which are highly resistant to water and can effectively prevent leaks and water damage on roofs. The application of waterproofing membranes on roofs is a proven method to enhance the longevity and durability of the roofing system, especially in areas prone to heavy rainfall or extreme weather conditions. Additionally, waterproofing membranes are flexible and can be easily installed on various types of roofing materials, including concrete, metal, or asphalt shingles. Therefore, if you want to ensure a watertight roof and protect your property from water-related issues, using waterproofing membranes is a reliable and effective solution.

- Q: Can a waterproofing membrane be used in planters or garden beds?

- Yes, a waterproofing membrane can be used in planters or garden beds to prevent water leakage and protect the surrounding areas. It helps to retain moisture in the soil and prevents water damage to the planter or garden bed structure.

Send your message to us

APP modified bitumen waterproof membrane

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords