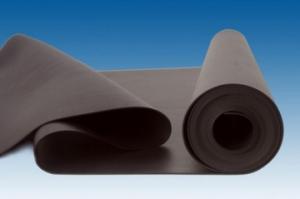

EPDM Rubber Waterproof Mmebrane for Basement Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Product characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Uses for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Data for EPDM Waterproof Membrane

NO | Item | unit | Technical requirement | |||

1 | Tolerance on size | Thickness | % | ±10 | ||

Width | % | ±1 | ||||

length | % | Does not allow negative | ||||

2 | Fracture tensile strength (normal temperature ) | Mpa | ≥7.5 | |||

Fracture tensile strength(60 degree) | Mpa | ≥2.3 | ||||

3 | Breaking elongation,(normal temperature ) | % | ≥450 | |||

Breaking elongation,(zero 20 degree) | % | ≥200 | ||||

4 | Tearing resistance | KN/m | ≥25 | |||

5 | impermeability | * | 0.3Mpa impermeable | |||

6 | Bending at low temperature | °C | ≤-40 | |||

7 | Elongation and contraction volume at heating | Elongation | mm | ≤2 | ||

contraction | mm | ≤4 | ||||

8 | Hot air aging 80°CX168h | Fracture strength retention | % | ≥80 | ||

Rate of elongation at break | % | ≥80 | ||||

9 | Alkaline (saturated Ca(OH)2 solution normal | Fracture strength retention | % | ≥80 | ||

Temperature x2 168h ) | Rate of elongation at break | % | ≥80 | |||

10 | Ozone aging (40 degree by 168 hours ) | Elongation 40% , 500x10-2 | * | No Crack | ||

11 | Phytotron aging | Fracture strength retention | % | ≥80 | ||

Rate of elongation at break | % | ≥70 | ||||

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a balcony?

- A balcony can indeed use a waterproofing membrane. Its purpose is to safeguard against water infiltration and shield surfaces from moisture-related harm. Since balconies are exposed to the elements and vulnerable to water damage, it is crucial to apply a waterproofing membrane in order to prolong their lifespan and maintain their structural soundness. By applying the membrane to the surface of the balcony, a barrier is created that effectively prevents water from seeping through cracks or joints. Consequently, this safeguards against water-related issues such as leaks, mold, and deterioration of structural components. It is of utmost importance to choose a high-quality waterproofing membrane that is specifically suitable for outdoor use and capable of withstanding exposure to UV rays, temperature fluctuations, and foot traffic. Consulting a professional contractor is recommended to ensure proper installation and to select the most appropriate waterproofing system tailored to the specific needs of your balcony.

- Q: Can a waterproofing membrane be used in residential buildings?

- Yes, a waterproofing membrane can be used in residential buildings. It is commonly used in basements, bathrooms, and other areas prone to moisture to prevent water damage and leakage.

- Q: Can a waterproofing membrane be used on roofs with standing water or ponding?

- No, a waterproofing membrane should not be used on roofs with standing water or ponding. While waterproofing membranes are designed to provide a protective barrier against water penetration, they are not meant to be submerged or exposed to constant water accumulation. Standing water or ponding on a roof can cause a variety of issues, such as increased weight load, potential structural damage, and increased risk of leaks. It is important to address any drainage issues and ensure proper roof slope to prevent standing water before considering the application of a waterproofing membrane.

- Q: Can a waterproofing membrane be used for a crawl space?

- Yes, a waterproofing membrane can be used for a crawl space. It can help prevent moisture from seeping into the crawl space, protecting the area from water damage and potential mold growth.

- Q: Can a waterproofing membrane be used in commercial buildings?

- Indeed, it is possible to utilize a waterproofing membrane in commercial establishments. Waterproofing membranes serve the purpose of safeguarding diverse sections of a building, encompassing roofs, foundations, and basements, against water infiltration. In the case of commercial buildings, where the likelihood of water harm is heightened due to larger surface areas, increased foot traffic, and intricate architectural designs, waterproofing membranes prove to be a viable solution. These membranes are specially crafted to establish a protective barrier against water, thereby averting leaks, moisture, and potential structural harm. Furthermore, the integration of waterproofing membranes contributes to the longevity of the building by reducing the risk of deterioration resulting from exposure to water. Consequently, the incorporation of a waterproofing membrane system in commercial establishments aids in maintaining a secure and dry environment, safeguarding valuable assets, and optimizing the lifespan of the structure.

- Q: Can waterproofing membranes be used on utility manholes?

- Utility manholes can indeed benefit from the use of waterproofing membranes. These specialized membranes are specifically engineered to create a barrier against water infiltration, making them perfectly suited for areas where water is present, such as manholes. To prevent any potential damage to the structure or the utilities within, these membranes are typically applied to the walls and floors of the manhole, effectively preventing water from seeping through. This process not only maintains the integrity and functionality of the utilities, but also helps to avoid water-related issues like corrosion, leaks, and material degradation. Furthermore, waterproofing membranes offer additional protection against elements such as chemicals, gases, and soil contaminants that may be found in or around the manhole. Thus, the application of waterproofing membranes on utility manholes is a widely adopted practice to guarantee their long-term durability and functionality.

- Q: Are there any specific considerations for installing a waterproofing membrane on masonry surfaces?

- Yes, there are several specific considerations to keep in mind when installing a waterproofing membrane on masonry surfaces. Firstly, it is important to thoroughly clean and prepare the masonry surface before installing the membrane. This includes removing any loose debris, dirt, or old coatings that could hinder the membrane's adhesion. Secondly, it is crucial to choose the right type of waterproofing membrane that is suitable for masonry surfaces. Masonry surfaces can vary in terms of porosity and texture, so selecting a membrane that is compatible with the specific type of masonry is important for achieving optimal results. Additionally, it is essential to ensure proper surface preparation and priming before applying the membrane. This may involve using a primer that helps improve adhesion and creates a strong bond between the masonry and the membrane. Moreover, the installation technique plays a crucial role in the effectiveness of the waterproofing membrane. Care should be taken to apply the membrane evenly and smoothly, avoiding any gaps, wrinkles, or air bubbles that might compromise its performance. It is also important to pay attention to the manufacturer's guidelines and recommendations regarding the application method and curing time. Lastly, regular inspection and maintenance are necessary to ensure that the waterproofing membrane remains in good condition over time. This may involve periodically checking for any signs of damage, such as cracks or peeling, and promptly addressing any issues that arise. By considering these specific factors, a waterproofing membrane can be effectively installed on masonry surfaces, providing long-lasting protection against water infiltration and damage.

- Q: Can a waterproofing membrane be applied to curved or irregular surfaces?

- Yes, a waterproofing membrane can be applied to curved or irregular surfaces. There are flexible waterproofing membranes available in the market that can conform to various shapes and contours. These membranes are designed to be stretchable and can be manipulated to fit curved or irregular surfaces without compromising their waterproofing capabilities. It is important to choose a membrane that is specifically designed for such applications and ensure proper installation techniques are followed to ensure a watertight seal.

- Q: Can waterproofing membranes be used on elevator pits?

- Yes, waterproofing membranes can be used on elevator pits. Elevator pits are prone to water infiltration, and using waterproofing membranes can help prevent water damage and corrosion in the pit area. The membranes create a barrier that prevents water from seeping into the pit, ensuring its dryness and structural integrity.

- Q: What is BSB waterproofing membrane

- ?Features: The coil has excellent high temperature resistance and can be used at -25 in the temperature range of + 100 ° C, with high elasticity and fatigue resistance, as well as up to 1500% elongation and strong puncture resistance , Tear-resistant cold. Suitable for cold areas, as well as deformation and vibration of large industrial and civil buildings waterproofing works. Low temperature flexibility is good, to -25 ℃ does not crack; high heat resistance 100 ℃ does not flow. Good extension performance, long service life, simple construction, small pollution and so on.

Send your message to us

EPDM Rubber Waterproof Mmebrane for Basement Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords