PVC Waterproofing Membrane Reinforced with Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane Reinforced with Fiberglass

Product Description of PVC Waterproofing Membrane Reinforced with Fiberglass:

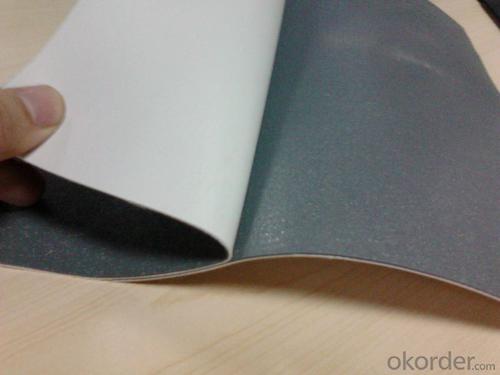

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane Reinforced with Fiberglass:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

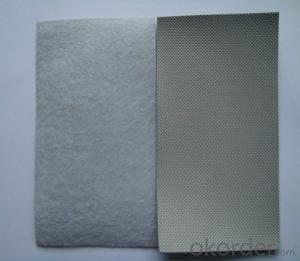

Classification of PVC Waterproofing Membrane Reinforced with Fiberglass:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane Reinforced with Fiberglass:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane Reinforced with Fiberglass:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane Reinforced with Fiberglass:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

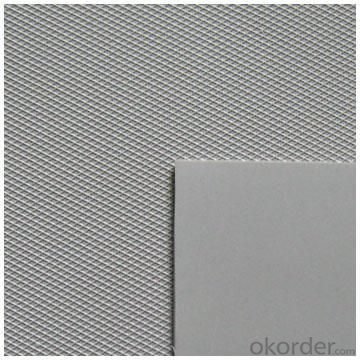

Images of PVC Waterproofing Membrane Reinforced with Fiberglass:

FAQ of PVC Waterproofing Membrane Reinforced with Fiberglass:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Podium decks or plaza areas can benefit from the application of a waterproofing membrane. It is highly recommended to utilize this protective layer in order to safeguard the underlying structure from water-related harm. Given their exposure to the elements, podium decks and plaza areas are susceptible to water infiltration. By implementing a waterproofing membrane, water seepage into the lower layers can be effectively prevented, thus ensuring the long-lasting durability and structural integrity of the deck or plaza. Furthermore, this waterproofing membrane is also capable of shielding spaces beneath the deck or plaza, such as basements or parking garages, from potential water damage. Therefore, it is crucial to select a top-notch waterproofing membrane specifically designed for outdoor purposes, and to carefully adhere to the manufacturer's instructions regarding proper installation and maintenance.

- Q: Is a waterproofing membrane resistant to impact or abrasion damage?

- Waterproofing membranes are usually designed to resist impact or abrasion damage to some extent, but the degree of resistance can differ based on the membrane's specific type and quality. In general, waterproofing membranes are engineered to endure normal wear and tear, including minor impacts and abrasions. They are typically made from durable materials like modified bitumen, PVC, EPDM, or polyurethane, which offer a certain level of impact and abrasion resistance. These materials are selected for their ability to withstand external forces and safeguard the underlying structure against water infiltration. Although most waterproofing membranes can withstand moderate impacts and abrasions, they may not be completely impervious to severe damage. Heavy impacts or sharp objects have the potential to puncture or tear the membrane, compromising its ability to prevent water penetration. Hence, it is crucial to handle and maintain the membrane with care to reduce the risk of damage. To enhance the impact and abrasion resistance of a waterproofing membrane even further, additional protective layers can be added. For instance, a layer of geotextile fabric or a cementitious coating can be applied over the membrane to provide extra strength and durability. In summary, while a waterproofing membrane is designed to resist impact and abrasion damage, the level of resistance can vary depending on the specific type and quality of the membrane. It is important to choose a high-quality membrane and take appropriate measures to minimize the risk of damage for long-lasting waterproofing performance.

- Q: Can waterproofing membranes be used on concrete manholes?

- Yes, waterproofing membranes can be used on concrete manholes. These membranes are specifically designed to create a barrier against water infiltration, protecting the structure from damage caused by moisture. Applying waterproofing membranes on concrete manholes can help prolong their lifespan and prevent issues such as leaks and deterioration.

- Q: What should the attention of the membrane waterproof construction?

- (4) Coil Lap Adhesive: After the web is compacted, the lap is opened and the lacquer is applied with the paint brush to apply the two adhesive surfaces of the coil joint. After a moment of dry feel when the sticky, you can glue, and then press the rubber hammer knocked dense, so as not to cause leakage of slit; (5) waterproof layer construction temperature selection above 5 ℃ is appropriate.

- Q: Can a waterproofing membrane be used on TPO roofs?

- Yes, a waterproofing membrane can be used on TPO roofs. TPO (thermoplastic olefin) is a popular roofing material that is known for its durability and energy efficiency. However, like any roofing material, TPO roofs can still be susceptible to leaks and water damage over time. To enhance the waterproofing capabilities of a TPO roof, a waterproofing membrane can be applied. A waterproofing membrane is a thin layer of material that is designed to prevent water infiltration. It is typically made from synthetic materials such as modified bitumen, EPDM, or PVC. These membranes are highly effective in creating a barrier against water, protecting the underlying roof structure from leaks and potential damage. When applying a waterproofing membrane on a TPO roof, it is important to ensure compatibility between the materials. The membrane should be specifically designed for use on TPO roofs and should be approved by the manufacturer of the TPO roofing system. This will ensure that the membrane is compatible with the TPO material and will not cause any adverse reactions or void any warranties. The installation of a waterproofing membrane on a TPO roof typically involves cleaning and preparing the surface, applying a primer if necessary, and then adhering the membrane to the roof using an appropriate adhesive or heat welding method. Once installed, the membrane acts as an extra layer of protection, preventing water from penetrating the TPO roof system and causing damage. In conclusion, a waterproofing membrane can be used on TPO roofs to enhance their waterproofing capabilities and protect against leaks. However, it is important to choose a membrane that is specifically designed for use on TPO roofs and is approved by the manufacturer of the TPO roofing system. Proper installation and regular maintenance will ensure the longevity and effectiveness of the waterproofing membrane on a TPO roof.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. A waterproofing membrane is a thin layer of material that is designed to prevent water or moisture from penetrating through to the underlying surface. It is commonly used in areas where water exposure is high, such as bathrooms, showers, or outdoor areas. When applied properly, a waterproofing membrane can create a barrier that protects the tile surface from water damage, preventing issues such as mold, mildew, or tile deterioration. It is important to ensure that the waterproofing membrane is compatible with the type of tile being used and that it is installed correctly to ensure maximum effectiveness.

- Q: Are waterproofing membranes UV resistant?

- Yes, waterproofing membranes are typically UV resistant. They are designed to withstand exposure to sunlight without degrading or losing their effectiveness. This UV resistance helps to prolong the lifespan of the membrane and maintain its waterproofing properties over time.

- Q: Are waterproofing membranes resistant to punctures?

- Yes, waterproofing membranes are designed to be resistant to punctures. These membranes are typically made from durable materials such as polyvinyl chloride (PVC), thermoplastic olefin (TPO), or ethylene propylene diene terpolymer (EPDM), which are known for their strength and ability to withstand external pressures. Additionally, waterproofing membranes are often reinforced with polyester or fiberglass to further enhance their puncture resistance. However, it is important to note that while waterproofing membranes are designed to be highly resistant to punctures, they may still be susceptible to damage if subjected to sharp objects or excessive force. Therefore, it is essential to handle and install these membranes with care to maintain their integrity and effectiveness.

- Q: Can a waterproofing membrane be installed on a roof?

- A roof can have a waterproofing membrane installed on it to prevent water from seeping through. This type of material is specifically designed to provide a protective layer, and when applied to a roof, it acts as a barrier against moisture, preventing leaks and water damage. It is commonly used on flat or low-sloped roofs where water accumulation can be problematic. To install the membrane, the roof surface is cleaned and prepared, and then the membrane is applied in overlapping layers and secured using adhesives, fasteners, or heat welding. In addition to preventing water damage, a waterproofing membrane also helps to extend the lifespan of a roof by protecting it from UV rays, temperature changes, and other environmental factors. Overall, installing a waterproofing membrane is an effective way to ensure the long-term durability of a roof and avoid water-related issues.

Send your message to us

PVC Waterproofing Membrane Reinforced with Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords