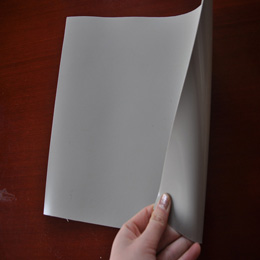

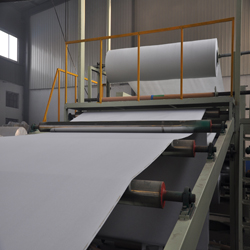

PVC waterproof membrane with fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

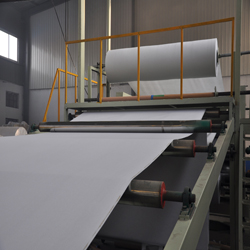

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC (polyvinyl chloride) roof membrane

is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer,

anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion

and molding.As the highly recommended product by the Ministry of Construction, it is featured by high tensile

strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to

weathering and root penetration, and long service life.

Physical Property:

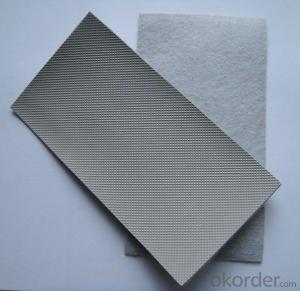

1.Good combination of high elasticity and tensile strength.

2.Fine resistance to static electricity.

3.Excellent resistance to ageing / weathering.

4.Durable,the effective age can be more than 20 years used on exposed surfaces,used on non-exposed surfaces,it can reach 50 years.

5.Fine flexibility at low temperature,adaptable to cold conditions.

6.Root-resistance,can be used on the planting roofs.

7.Fine puncture resistance, joint peel strength and joint shear strength.

8.Fine UV-resistance,no pollution to environment.

9.Easily welding,installing,secure.

10.Easy treatments to the delicate parts of corners and edges.

11.Convenient maintenance with low cost.

Polyvinyl Chloride (PVC) membrane with fiber reinforced layer

on the back is widely used in the roofs of civil buildings,

tunnels, channels, subways, highways, planting roofs, the roofs of steel

frame structure buildings, and etc.

- Q: Can a waterproofing membrane be recycled or disposed of in an environmentally friendly manner?

- Indeed, a waterproofing membrane has the potential to be recycled or disposed of in an environmentally conscious manner. Numerous waterproofing membranes are crafted from recyclable materials like polyethylene or polypropylene, which can be repurposed into new products. The act of recycling these membranes not only diminishes waste, but it also conserves resources and lessens the environmental impact associated with manufacturing fresh materials. In order to recycle a waterproofing membrane, it is crucial to consult local recycling facilities or waste management centers to determine if they accept this specific type of material. Some facilities might have specific guidelines or procedures for recycling membranes, thus adhering to their instructions is of utmost importance. In instances where recycling is not feasible, it is still possible to dispose of the waterproofing membrane in an environmentally friendly manner. Numerous waste management facilities allocate designated areas for construction and demolition waste, providing a proper means of disposing the membrane. These facilities employ methods that minimize the environmental impact of the waste, such as containment and controlled disposal techniques. It is of utmost importance to refrain from tossing the membrane in regular trash or illegally dumping it, as this could harm the environment and contribute to pollution. Proper disposal ensures that any potential pollutants or contaminants within the membrane are appropriately managed, thereby preventing harm to ecosystems and human health. In conclusion, by actively engaging in the recycling or environmentally friendly disposal of a waterproofing membrane, we can contribute to a future that is more sustainable and cleaner.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. It is a common practice to use waterproofing membranes in underground structures to prevent water infiltration and protect the structural integrity of the tunnels or subway systems. These membranes are designed to provide a barrier against water, ensuring the safety and longevity of the underground infrastructure.

- Q: Can a waterproofing membrane be customized or tailored to specific project requirements?

- Yes, a waterproofing membrane can be customized or tailored to specific project requirements. Different projects may have unique needs such as different levels of water exposure, environmental conditions, or structural requirements. In such cases, the selection of materials, thickness, and installation methods can be customized to ensure optimal waterproofing performance and durability for the specific project.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to create a barrier against moisture, preventing water penetration into structures. This makes them an effective solution for underground bunkers, which are susceptible to water infiltration due to their underground location. By applying a waterproofing membrane to the walls and floor of the bunker, it can help to prevent water seepage and keep the interior dry. This is crucial for the protection of any stored items or occupants within the bunker. Additionally, waterproofing membranes can also provide added benefits such as insulation and protection against radon gas. It is important to ensure that the chosen membrane is specifically designed for underground applications and can withstand the unique conditions and pressures associated with being underground.

- Q: Can a waterproofing membrane be used for swimming pool decks and patios?

- Yes, a waterproofing membrane can be used for swimming pool decks and patios. A waterproofing membrane is designed to prevent water penetration and protect the underlying structure from water damage. Swimming pool decks and patios are constantly exposed to water, whether through splashing or rain, making them susceptible to water damage. By applying a waterproofing membrane, you can ensure that the pool deck or patio remains protected and free from water-related issues such as cracking, mold, or deterioration. This membrane acts as a barrier, preventing water from seeping into the concrete or other materials, thus extending the lifespan of the pool deck or patio. It is essential to choose a high-quality and suitable waterproofing membrane specifically designed for outdoor use to ensure optimal performance and durability.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Yes, waterproofing membranes can be used on both horizontal and vertical surfaces.

- Q: How does a waterproofing membrane handle freeze-thaw cycles?

- A waterproofing membrane is designed to handle freeze-thaw cycles by being flexible and resistant to cracking. It should be able to expand and contract with temperature fluctuations without compromising its waterproofing properties. Additionally, it should have good adhesion to the substrate to prevent water infiltration and damage during these cycles.

- Q: Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. Waterproofing membranes are designed to prevent water penetration and moisture buildup, making them an ideal solution for areas that are prone to water damage, such as basements, bathrooms, and kitchens. These membranes create a barrier that prevents water from seeping through floors, walls, or other surfaces, effectively protecting the structure from water-related issues like mold, rot, and structural damage. Additionally, waterproofing membranes can also help regulate humidity levels, leading to a more comfortable and healthier indoor environment.

- Q: Can waterproofing membranes be used on concrete stairs?

- Yes, waterproofing membranes can be used on concrete stairs. These membranes are designed to create a protective barrier against water penetration, which is particularly important for areas exposed to moisture such as outdoor or basement stairs. Applying a waterproofing membrane on concrete stairs can help prevent water damage, increase their durability, and extend their lifespan.

- Q: Can waterproofing membranes be used on terraces?

- Yes, waterproofing membranes can definitely be used on terraces. In fact, using waterproofing membranes on terraces is highly recommended to protect the structural integrity of the terrace and prevent water damage. Waterproofing membranes act as a barrier, preventing water from seeping into the terrace and causing leaks or cracks. They are commonly used on flat terraces, rooftop terraces, and balconies to ensure that water does not penetrate the surface and cause damage to the underlying structure. Waterproofing membranes are available in various types, such as liquid-applied membranes, sheet membranes, and self-adhesive membranes, providing different options to suit the specific needs and requirements of the terrace. By applying a waterproofing membrane, the terrace can be protected from moisture, UV rays, and other environmental factors, extending its lifespan and ensuring a durable and long-lasting surface.

Send your message to us

PVC waterproof membrane with fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords