PVC Roofing Waterproof Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

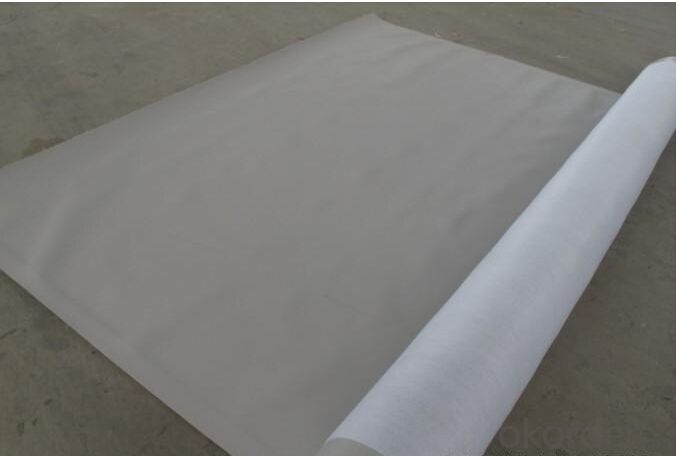

Introduction of PVC Waterproof Membrane

It is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti-aging agent, and stabilizer and other processing aids through extrusion and molding.

As the highly recommended product by the Ministry of Consturction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to weathering and root penetration and long service life.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: How does a waterproofing membrane handle water infiltration from above?

- The purpose of a waterproofing membrane is to prevent water infiltration from above. It achieves this by creating a barrier that is impermeable to water. Typically, the membrane is made of a durable and flexible material, such as rubber or asphalt, which is specifically designed to withstand exposure to water. When water comes into contact with the surface above the waterproofing membrane, it acts as a protective layer that stops the water from seeping through and reaching the underlying structure. The membrane effectively repels the water, ensuring that it does not enter the building or any other protected area. To further enhance its resistance to water, the membrane is often installed with overlapping seams and sealed using adhesive or heat to create a continuous and watertight barrier. This prevents any potential gaps or weak points where water could potentially seep in. In addition to its impermeability, a waterproofing membrane is also designed to handle water infiltration by providing drainage pathways for any accumulated water on its surface. This is achieved through the use of channels or slopes that direct the water away from the protected area, effectively draining it and preventing any damage caused by water accumulation. Overall, a waterproofing membrane is specifically engineered to handle water infiltration from above. It accomplishes this by creating a strong and impenetrable barrier, as well as providing effective drainage mechanisms to prevent water accumulation.

- Q: Are waterproofing membranes resistant to earthquake-induced water pressure?

- Yes, waterproofing membranes are designed to be resistant to earthquake-induced water pressure. These membranes are specifically engineered to provide a barrier against water infiltration, even under high-pressure situations caused by an earthquake.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Underground communication vaults are typically made of concrete or other materials that are susceptible to water infiltration. To prevent water damage and ensure the longevity of the vault, a waterproofing membrane can be applied to the exterior surface of the vault. This membrane acts as a barrier, preventing water from entering the vault and causing damage to the equipment or infrastructure inside. Additionally, the waterproofing membrane can also protect against other potential threats such as moisture, chemicals, and soil gases. It is important to choose a high-quality waterproofing membrane that is specifically designed for underground structures to ensure its effectiveness and long-term durability.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Indeed, water treatment plants can benefit from the utilization of waterproofing membranes. These specialized membranes are specifically engineered to impede the flow of water, making them an ideal solution for safeguarding against water seepage in diverse structures, including water treatment plants. By applying these membranes to various sections of the facility, such as tanks, reservoirs, pipes, and basements, infiltration of water can be effectively prevented, thus shielding the infrastructure from potential harm. Furthermore, the implementation of waterproofing membranes aids in preserving the integrity of the water treatment process by ensuring that water remains confined within designated areas and does not permeate the surrounding soil or structures.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Indeed, wastewater treatment plants and sewage facilities require protection against water infiltration and leakage due to the abundance of water and potentially corrosive substances. To address this issue, a versatile solution in the form of a waterproofing membrane can be utilized. This membrane acts as a barrier, preventing water penetration and safeguarding the structure from damage while ensuring the facility's proper functioning. Its application extends to various areas such as walls, floors, roofs, and tanks, effectively maintaining a watertight environment and prolonging the facility's lifespan. Moreover, certain waterproofing membranes are specifically engineered to withstand harsh chemicals, making them ideal for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. Laundry rooms are areas where water and moisture are commonly present due to washing machines, sinks, and other water-related activities. Installing a waterproofing membrane in the laundry room can help prevent water damage to the walls, floors, and other structural components. It acts as a barrier against water penetration, ensuring that any water or moisture that accumulates in the room does not seep into the underlying surfaces. This can be particularly beneficial in laundry rooms located on upper floors or in areas prone to high humidity or flooding. By using a waterproofing membrane, homeowners can protect their laundry rooms from potential water-related issues, such as mold growth, rotting, or structural damage.

- Q: Can a waterproofing membrane be used for restaurants or kitchens?

- Yes, a waterproofing membrane can be used for restaurants or kitchens. Waterproofing membranes are commonly used in these areas to protect the underlying structure from water damage. They are typically installed in areas prone to water exposure such as floors, walls, and countertops. Waterproofing membranes help prevent water from seeping into the building materials, which can cause deterioration, mold growth, and other issues. Additionally, these membranes are designed to be resistant to chemicals and stains commonly found in restaurant or kitchen settings. Overall, using a waterproofing membrane is an effective way to ensure the durability and longevity of the restaurant or kitchen, while also maintaining a clean and hygienic environment.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on precast concrete surfaces. Here are a few key points to keep in mind: 1. Surface Preparation: Before applying the waterproofing membrane, it is crucial to prepare the precast concrete surface properly. This may involve cleaning the surface, removing any loose particles, and ensuring that it is dry and free from any contaminants. 2. Compatibility: It is important to choose a waterproofing membrane that is compatible with precast concrete surfaces. Some membranes may not adhere well or may not provide effective waterproofing on this type of substrate. Therefore, it is essential to select a membrane specifically designed for use on precast concrete. 3. Adhesion: Ensuring proper adhesion of the waterproofing membrane to the precast concrete surface is vital. The manufacturer's instructions should be followed carefully, including any surface priming or preparation requirements for optimal adhesion. Proper adhesion will help prevent any water infiltration or damage to the concrete. 4. Joint Treatment: Precast concrete surfaces often have joints between panels or other components. These joints need to be properly treated to maintain the waterproofing integrity of the system. This may involve using joint sealants or tapes specifically designed for waterproofing purposes. 5. Durability: Consider the durability and longevity of the waterproofing membrane. Precast concrete surfaces are often exposed to various weather conditions and environmental factors. Therefore, it is crucial to select a membrane that can withstand these conditions and provide long-term protection against water penetration. 6. Quality Assurance: It is recommended to work with experienced professionals or certified installers to ensure the proper installation of the waterproofing membrane on precast concrete surfaces. This will help to minimize any potential installation errors and ensure that the waterproofing system performs as intended. By considering these specific considerations, the installation of a waterproofing membrane on precast concrete surfaces can help protect the concrete from water damage and extend its lifespan.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Certainly! A waterproofing membrane is suitable for both pond and pool applications. Its main purpose is to create a barrier that prevents water from penetrating, making it an excellent choice for sealing ponds and pools. These membranes are typically made from synthetic materials like PVC, EPDM, or TPO, all of which have high resistance to water and UV rays. They come in different thicknesses and can be tailored to fit the specific dimensions of the pond or pool. Moreover, waterproofing membranes are incredibly durable and flexible, allowing them to withstand continuous exposure to water and the movement of the underlying substrate. In summary, utilizing a waterproofing membrane for pond or pool applications helps avoid leaks, extends the lifespan of the structure, and guarantees a safe and enjoyable water environment.

- Q: Can a waterproofing membrane be applied in cold weather conditions?

- Yes, a waterproofing membrane can be applied in cold weather conditions. However, it is important to note that the specific temperature range in which it can be applied may vary depending on the product and manufacturer guidelines. Some waterproofing membranes are designed to withstand cold temperatures and can be applied as low as -20 degrees Celsius (-4 degrees Fahrenheit), while others may have a higher minimum application temperature. It is crucial to follow the instructions provided by the manufacturer and ensure that the surface is properly prepared and free from any ice, snow, or moisture. Additionally, it is recommended to consult with a professional contractor who has experience working with waterproofing membranes in cold weather conditions to ensure the best results.

Send your message to us

PVC Roofing Waterproof Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords