Green Plastic Roofing Sheets

Green Plastic Roofing Sheets Related Searches

Plastic Coated Steel Roofing Sheets Garden Plastic Sheeting House Roof Sheets Pp Roofing Sheets Roofing Plywood Sheets Colour Roofing Sheet Structural Plastic Sheets Lightweight Plastic Sheets Green Plastic Netting Fiberglass Sheets For Roofing Fitting Corrugated Plastic Roofing Sheets Plastic Film Sheets Buy Sheet Plastic Buy Roofing Sheets Online Clear Plastic Sheets Colored Plastic Sheeting Rolls Protective Plastic Sheeting Corrigated Plastic Roofing Thin Hard Plastic Sheets Plastic Sheets For Sale Flat Plastic Sheets Coroline Roofing Sheets Corrugated Shed Roof Sheets Greenhouse Plastic Sheeting South Africa Green Plastic Fencing Roll Fiber Sheet For Roof Thin Transparent Plastic Sheet Large Rolls Of Plastic Sheeting Fitting Polycarbonate Roofing Sheets Polycarbonate Sheet RoofingGreen Plastic Roofing Sheets Supplier & Manufacturer from China

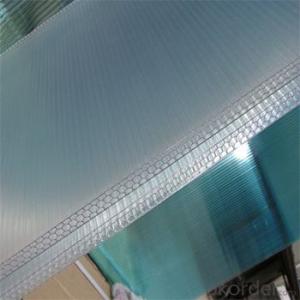

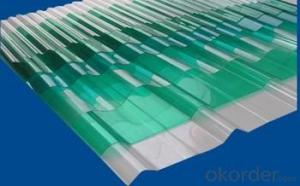

Green Plastic Roofing Sheets are a type of eco-friendly roofing solution made from recycled materials, designed to provide durability, weather resistance, and sustainability. These sheets are an excellent choice for various construction projects, offering a cost-effective and environmentally conscious alternative to traditional roofing materials. They are widely used in residential, commercial, and agricultural buildings, as well as in temporary structures and sheds, due to their lightweight, easy installation, and low maintenance requirements.Green Plastic Roofing Sheets are particularly beneficial in scenarios where a quick and efficient roofing solution is needed, such as in disaster relief efforts or rapid construction projects. Their ability to withstand harsh weather conditions, including heavy rain, snow, and high winds, makes them a popular choice for regions with extreme climates. Additionally, the vibrant green color of these sheets adds an aesthetic appeal to the structures they cover, blending well with natural surroundings and contributing to a visually pleasing exterior.

Okorder.com is a leading wholesale supplier of Green Plastic Roofing Sheets, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Green Plastic Roofing Sheets they provide meet the highest industry standards. Their extensive selection and competitive pricing make them an ideal choice for contractors, builders, and DIY enthusiasts looking to invest in sustainable and long-lasting roofing solutions.

Hot Products