EPDM Waterproof Rubber Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Rubber Membrane with 1.2mm Thickness

Description Of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

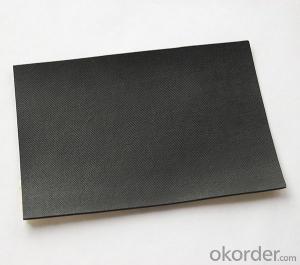

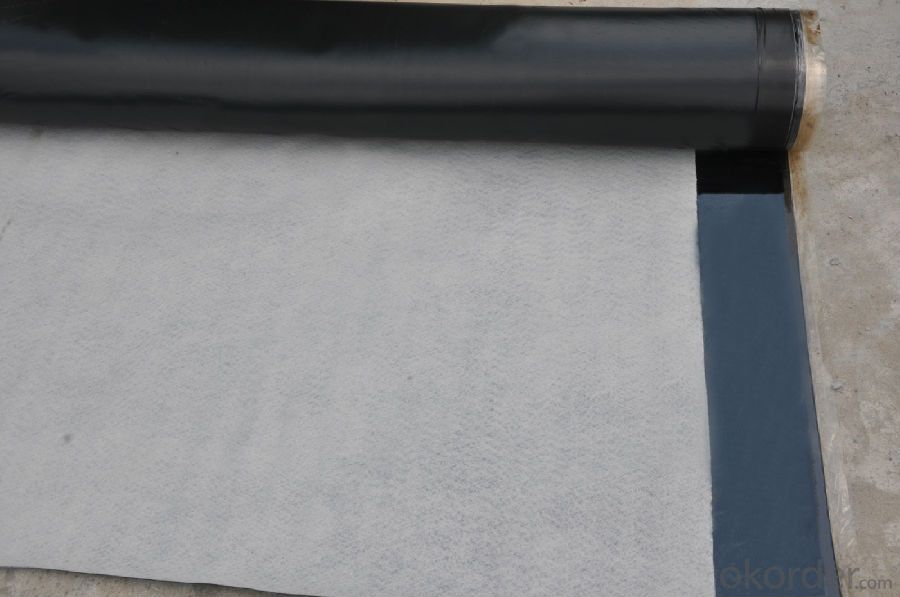

IMages of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

FAQ of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used on tunnels with historical significance?

- Yes, a waterproofing membrane can be used on tunnels with historical significance. The use of a waterproofing membrane is a common method to prevent water infiltration and damage in tunnels, regardless of their historical significance. It is crucial to protect these tunnels from water damage, as moisture can lead to deterioration, structural issues, and even collapse over time. However, when working with tunnels of historical significance, it is important to take additional precautions to preserve their historical integrity. This may involve using a waterproofing membrane that is visually compatible with the tunnel's original materials, ensuring that the installation does not disrupt or damage any historical features, and obtaining the necessary permissions, permits, and approvals from relevant historical preservation authorities. By following these guidelines, it is possible to effectively waterproof tunnels with historical significance while also preserving their historical and cultural value.

- Q: Are waterproofing membranes resistant to oil and fuel spills?

- Yes, waterproofing membranes are designed to be resistant to oil and fuel spills. They are specially formulated to provide a barrier against these substances, preventing them from penetrating the membrane and causing damage.

- Q: Can a waterproofing membrane be used on flat roofs?

- Flat roofs can indeed benefit from the use of a waterproofing membrane. This method is widely recognized as one of the most effective and commonly used techniques for achieving waterproofing on flat roofs. The membrane itself is a thin material that is carefully applied to the roof's surface in order to prevent any water from seeping through. Typically constructed from durable and flexible substances like synthetic rubber or modified bitumen, the membrane is designed to withstand harsh weather conditions and offer long-lasting protection. By installing the membrane in overlapping layers, a continuous barrier is created that effectively seals the roof, preventing any water leakage into the building. Additionally, it is worth noting that waterproofing membranes can also provide insulation and energy efficiency advantages, which further contributes to their popularity in flat roof applications.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile and can be applied to various materials, including wood. They provide a protective barrier that prevents water from penetrating the wood, helping to prolong its lifespan and prevent damage caused by moisture.

- Q: Can waterproofing membranes be used on utility vaults?

- Yes, waterproofing membranes can be used on utility vaults. Utility vaults are typically underground structures that house important utility equipment such as electrical transformers, water meters, or communication systems. These vaults are susceptible to water infiltration, which can cause damage to the equipment and compromise its functionality. Waterproofing membranes are a common solution to prevent water from entering utility vaults. These membranes are typically made of durable materials such as rubber, PVC, or modified bitumen, which provide an impermeable barrier against water. They are applied to the walls and floors of the vault, creating a watertight seal that prevents moisture from seeping in. By using waterproofing membranes on utility vaults, the risk of water damage is significantly reduced. This helps to ensure the functionality and longevity of the equipment housed inside. Additionally, waterproofing membranes can also provide protection against other potential issues such as leaks, corrosion, and chemical damage. However, it is important to note that the application of waterproofing membranes on utility vaults requires proper surface preparation and installation techniques to ensure a successful and long-lasting waterproofing system. Therefore, it is recommended to consult with a professional waterproofing contractor who has experience in working with utility vaults to ensure the best results.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. However, to ensure effective installation, it is important to properly prepare the surface by leveling or smoothing it out as much as possible before applying the membrane.

- Q: Can a waterproofing membrane be used for a shower enclosure?

- Yes, a waterproofing membrane can be used for a shower enclosure. Waterproofing membranes are designed to prevent water from seeping through surfaces and causing damage. In a shower enclosure, where water exposure is high, a waterproofing membrane can be applied to the walls and floor to create a protective barrier. This helps to ensure that water does not penetrate the surrounding structure, preventing issues such as mold, rot, and water damage. It is important to choose a waterproofing membrane specifically designed for showers and follow the manufacturer's instructions for proper installation to ensure the best results.

- Q: Is a waterproofing membrane environmentally friendly?

- Yes, a waterproofing membrane can be environmentally friendly. Many modern waterproofing membranes are made from sustainable materials, such as recycled rubber or PVC-free compounds. Additionally, some membranes are designed to be easily recyclable at the end of their lifespan, reducing waste. Furthermore, a properly installed and maintained waterproofing membrane can help prevent water damage and mold growth, leading to a healthier and more sustainable environment.

- Q: How does a waterproofing membrane handle expansion and contraction of the substrate?

- A waterproofing membrane is designed to handle expansion and contraction of the substrate by being flexible and elastic. When the substrate expands or contracts due to temperature changes or other factors, the waterproofing membrane can stretch or shrink accordingly without undergoing any damage or failure. The membrane's flexibility allows it to adjust to the movements of the underlying substrate, ensuring that it remains intact and fully functional. This flexibility is achieved through the use of materials that have high elongation properties, such as modified bitumen, rubberized asphalt, or synthetic polymers like PVC or TPO. In addition to being flexible, a waterproofing membrane also has a high tensile strength, which enables it to resist tearing or breaking under the stress caused by expansion and contraction. This strength is crucial in preventing any water infiltration or moisture damage to the substrate. Furthermore, the installation of a waterproofing membrane often involves overlapping or interlocking the membrane sheets. These overlapping seams provide additional protection against any potential movement of the substrate. If the substrate expands or contracts, the overlapping seams allow the membrane to accommodate the movement while maintaining a continuous and watertight barrier. Overall, a waterproofing membrane is specifically designed to handle the expansion and contraction of the substrate. Its flexibility, high tensile strength, and overlapping seams ensure that it remains durable, reliable, and effective in preventing water penetration even as the substrate moves.

Send your message to us

EPDM Waterproof Rubber Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords