SBS Modified Bitumen Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

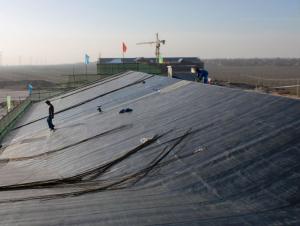

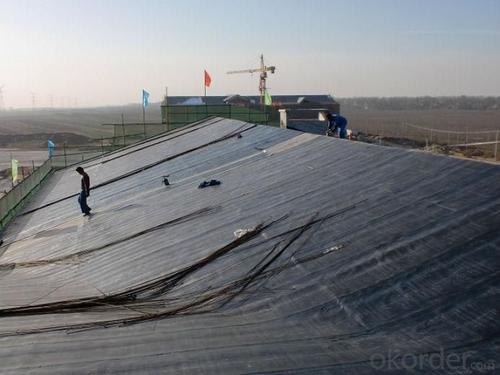

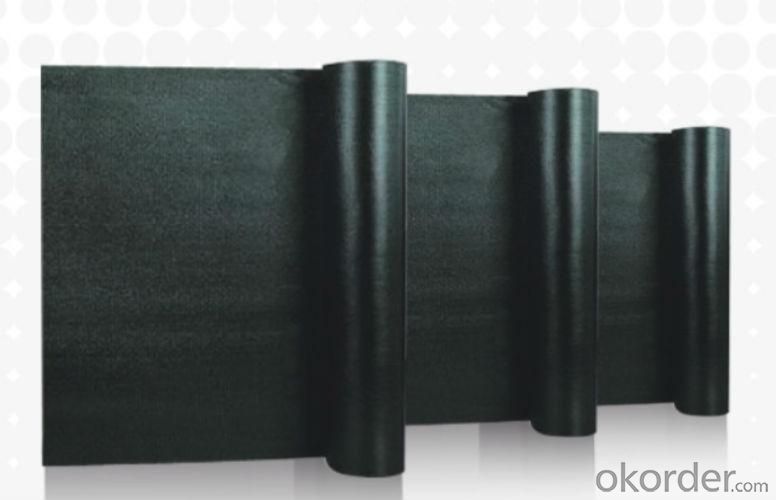

SBS modified bitumen waterproofing membrane is made by soaking the base in bitumen,or thermoplas ticityelastomer(such as styrene butadiene-SBS), modified bitumen, then covering double faces with elastomer(SBS) modified bitumen, and last finiishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

Specification of SBS/APP Polyester Waterproofing Membrane:

|

N |

ITEM |

STANDARD |

TEST RESULT |

||

|

1

|

WATER IMPERMEABILITY |

PRESSUREMpa |

>0.3 |

NO IMPERAMEABILITY |

|

|

KEEPING TIME, min |

120MIN |

||||

|

2 |

TENSION N/5cm |

≥300 |

MEET ASTM-D5147 |

||

|

3 |

FRACTURE ELONGATION,% |

≥450 |

LONGTIUDINAL550.0 TRANSVERSE 510.0 |

||

|

4 |

SOFTEN POINT |

110°C, |

MEET ASTM-D 5147 |

||

|

5 |

COLD FLEXIBILITY |

≥0(-20) |

MEET ASTM-D 5147 |

||

|

6 |

ELONGATION |

≥45 |

47 |

||

|

7 |

APP/SBS WATERPROOF MEMBRANE MEET DEMAND OF ASTM STANDARD |

||||

Characteristics Of SBS/APP Waterproofing Membrane :

It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature;

Easy application , no pollution, and long service life etc.

- Q: Can waterproofing membranes be used on swimming pool decks?

- Yes, waterproofing membranes can be used on swimming pool decks to protect them from water damage and leaks.

- Q: Can waterproofing membranes be used on utility manholes?

- Utility manholes can indeed benefit from the use of waterproofing membranes. These specialized membranes are specifically engineered to create a barrier against water infiltration, making them perfectly suited for areas where water is present, such as manholes. To prevent any potential damage to the structure or the utilities within, these membranes are typically applied to the walls and floors of the manhole, effectively preventing water from seeping through. This process not only maintains the integrity and functionality of the utilities, but also helps to avoid water-related issues like corrosion, leaks, and material degradation. Furthermore, waterproofing membranes offer additional protection against elements such as chemicals, gases, and soil contaminants that may be found in or around the manhole. Thus, the application of waterproofing membranes on utility manholes is a widely adopted practice to guarantee their long-term durability and functionality.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. It is a common practice to apply waterproofing membranes on masonry surfaces to prevent water penetration and protect the structure from moisture damage.

- Q: Can a waterproofing membrane be applied to uneven surfaces?

- Yes, a waterproofing membrane can be applied to uneven surfaces. However, the level of success and effectiveness may vary depending on the severity of the unevenness. It is important to properly prepare the surface by removing any loose debris, filling in large gaps or holes, and smoothening out any high points or ridges. There are also certain types of waterproofing membranes that are more flexible and can conform to uneven surfaces better than others. It is recommended to consult with a professional waterproofing contractor who can assess the condition of the surface and recommend the most suitable waterproofing membrane for the specific unevenness.

- Q: Roof SBS waterproofing membrane can not empty shop

- 3, under normal circumstances, with ordinary SBS coil roof waterproof, to Shitao as well, to prevent the emergence of a little water into the overall failure of the string of water phenomenon.

- Q: Are waterproofing membranes environmentally friendly?

- Waterproofing membranes can vary in their environmental impact depending on the materials used. Some waterproofing membranes, such as those made from recycled materials or natural substances, can be considered more environmentally friendly. However, other membranes made from synthetic materials or those containing harmful chemicals may have a negative impact on the environment. It is essential to consider the specific type of membrane and its composition to determine its overall environmental friendliness.

- Q: What is the cost of installing a waterproofing membrane?

- The cost of installing a waterproofing membrane can vary depending on several factors such as the size of the area to be waterproofed, the type of membrane used, and the complexity of the installation. On average, the cost can range from $3 to $10 per square foot. However, it is recommended to obtain quotes from professional contractors to get an accurate estimate for your specific needs.

- Q: Can waterproofing membranes be applied over existing surfaces?

- Yes, waterproofing membranes can be applied over existing surfaces. In fact, this is a common practice in construction and renovation projects. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied over various surfaces such as concrete, wood, metal, or even other waterproofing systems. By applying a waterproofing membrane over an existing surface, it helps to prevent water damage, including leaks, mold growth, and structural deterioration. However, it is important to ensure that the existing surface is properly prepared and cleaned before the membrane application to achieve optimal adhesion and performance. Additionally, it is recommended to consult with a professional waterproofing contractor to determine the most suitable membrane type and installation method for the specific project requirements.

- Q: Can waterproofing membranes be used in swimming pools?

- Indeed, swimming pools can make use of waterproofing membranes. To prevent water leakage and safeguard the pool's structural integrity, it is common practice to employ waterproofing membranes in swimming pools. These membranes, often constructed from sturdy materials like PVC or EPDM, are specifically engineered to endure continuous exposure to water and pool chemicals. They are applied to the concrete or other pool structures, forming a watertight barrier that thwarts any seepage of water. Furthermore, waterproofing membranes offer an added layer of defense against cracks, corrosion, and other types of harm, thus guaranteeing the long-lastingness and resilience of the pool.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- When installing a waterproofing membrane, there are various safety precautions to consider. To begin with, it is crucial to ensure that the installation team uses all necessary personal protective equipment (PPE). This may incorporate gloves, safety glasses, and appropriate footwear to prevent injuries or exposure to dangerous substances. Moreover, it is essential to work in a well-ventilated area to avoid inhaling fumes or vapors emitted during the installation process. If working in a confined space, it is necessary to take proper measures to guarantee sufficient ventilation and use suitable respiratory protection if needed. Furthermore, it is vital to adhere to the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This involves understanding any potential hazards linked with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to make sure that the installation area is appropriately prepared before commencing the process. This might entail clearing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and easily accessible first aid kits in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to promptly identify and address any potential safety risks. By adhering to these safety precautions, the installation of a waterproofing membrane can be carried out securely and effectively, minimizing the risk of accidents or injuries.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1991 |

| Annual Output Value | >RMB 150 millions |

| Main Markets | China; Southeast Asia; |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai port |

| Export Percentage | >50% |

| No.of Employees in Trade Department | 10-15 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | >150000 Square metres |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

SBS Modified Bitumen Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords