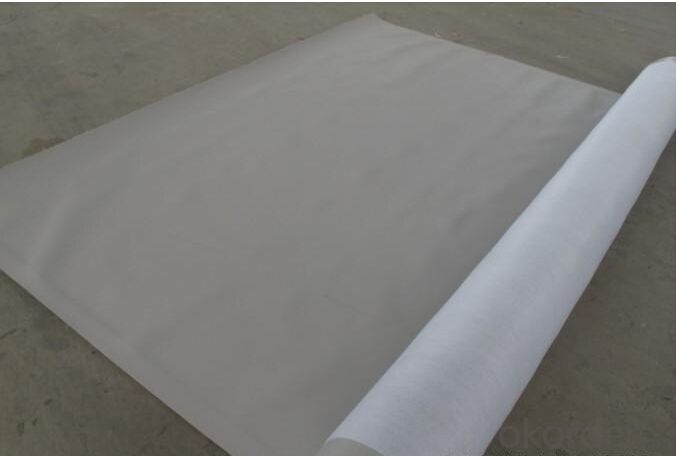

PVC Roofing Waterproof Membrane/Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane. The raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Yes, a waterproofing membrane can be used on rubber surfaces.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Indeed, rooftops with gardens can benefit greatly from the utilization of a waterproofing membrane. Employing a waterproofing membrane is strongly advised as it shields the foundational framework from harm caused by water. Given that a rooftop garden contributes additional weight and moisture to the roof, it is imperative to have a reliable waterproofing system in place to avert leaks and guarantee the roof's durability. The waterproofing membrane serves as a safeguard against water infiltration, effectively maintaining dry conditions for both the rooftop garden and the underlying structure.

- Q: How does a waterproofing membrane handle construction vibrations?

- A waterproofing membrane is designed to handle construction vibrations by providing a durable and flexible barrier that can withstand the movement and impact caused by these vibrations. The membrane is typically made of materials such as rubberized asphalt or synthetic polymers, which have excellent elasticity and tensile strength. When construction vibrations occur, the waterproofing membrane absorbs and dissipates the vibrations, preventing them from affecting the structural integrity of the building or compromising the waterproofing system. The flexibility of the membrane allows it to stretch and contract, accommodating the movement caused by vibrations without cracking or tearing. Additionally, some waterproofing membranes have added features like reinforced layers or fabric reinforcement, which further enhance their ability to withstand construction vibrations. These reinforcements provide additional strength and stability to the membrane, making it more resistant to damage from vibrations. It is important to note that the effectiveness of a waterproofing membrane in handling construction vibrations also depends on the quality of installation. Proper installation techniques, including adequate surface preparation and appropriate adhesion methods, ensure that the membrane is securely attached to the substrate, minimizing the risk of displacement or damage during construction activities. In summary, a waterproofing membrane is specifically designed to handle construction vibrations by absorbing and dissipating the impact, while maintaining its integrity and waterproofing capabilities. The flexibility and strength of the membrane, along with proper installation techniques, ensure that it can withstand the challenges posed by construction vibrations and provide long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used for swimming pool decks and patios?

- Swimming pool decks and patios are commonly subjected to water exposure, which can cause damage. To counter this, a waterproofing membrane can be utilized. This membrane serves as a shield to prevent water penetration and safeguard the underlying structure. Whether it's due to splashing or rainfall, these areas are prone to water-related issues like cracking, mold growth, and deterioration. By applying a waterproofing membrane, you can effectively protect your pool deck or patio from such problems. This protective barrier hinders water from seeping into the concrete or other materials, thus prolonging the lifespan of these surfaces. To guarantee optimum performance and durability, it is crucial to select a high-quality, outdoor-specific waterproofing membrane.

- Q: Can waterproofing membranes be used on utility tunnels?

- Utility tunnels, which are often exposed to moisture and water infiltration, can benefit from the use of waterproofing membranes. These membranes serve to safeguard the tunnel structure against water damage and ensure its longevity. Their purpose is to establish a barrier between the structure and its surroundings, effectively halting the seepage of water into the tunnel. Typically crafted from materials like bitumen or synthetic polymers, these membranes possess remarkable resistance against water penetration. By applying them to the walls, floors, and ceilings of utility tunnels, they provide comprehensive protection against water-related issues, including leaks, cracks, and deterioration. Furthermore, waterproofing membranes also play a vital role in upholding the integrity of utility tunnels by thwarting the influx of harmful substances such as chemicals or pollutants. In conclusion, the application of waterproofing membranes to utility tunnels represents a highly effective means of guaranteeing their long-term durability and functionality.

- Q: How does a waterproofing membrane handle hydrostatic pressure?

- A waterproofing membrane handles hydrostatic pressure by acting as a barrier between water and the structure it is applied to. When exposed to hydrostatic pressure, which is the pressure exerted by standing or moving water, the membrane forms a continuous seal that prevents water from penetrating into the structure. The membrane is designed to be impermeable, meaning that it does not allow water molecules to pass through it. It is typically made of materials such as rubber, PVC, or bitumen that have high resistance to water penetration. These materials are also flexible, allowing the membrane to conform to the contours of the surface it is applied to and provide a tight seal. When hydrostatic pressure is applied to the membrane, it resists the force and prevents water from infiltrating the structure. The membrane's resistance to water pressure is a result of its thickness, strength, and the quality of its installation. Thicker membranes are generally more resistant to hydrostatic pressure, while a properly installed membrane with no gaps, voids, or overlaps enhances its effectiveness in handling water pressure. In addition to providing a barrier against water penetration, some waterproofing membranes are also designed to accommodate movement caused by hydrostatic pressure. They can stretch or elongate to accommodate the expansion and contraction of the structure due to varying water levels or other external forces. This flexibility helps the membrane maintain its integrity and prevent water from seeping through. Overall, a waterproofing membrane effectively handles hydrostatic pressure by providing a continuous, impermeable barrier that resists the force of standing or moving water and prevents it from infiltrating the structure. Its ability to withstand water pressure is dependent on its thickness, strength, installation quality, and flexibility to accommodate movement.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: Can waterproofing membranes be used on mechanical rooms?

- Yes, waterproofing membranes can be used on mechanical rooms. Mechanical rooms often house equipment such as boilers, pumps, and ventilation systems, which can be sensitive to water damage. Waterproofing membranes provide a protective barrier against water infiltration and can help prevent leaks, moisture buildup, and potential damage to the equipment. Additionally, these membranes can also provide thermal insulation, noise reduction, and fire resistance properties. It is important to choose the appropriate type of waterproofing membrane based on the specific needs and requirements of the mechanical room.

- Q: Is a waterproofing membrane resistant to saltwater or other corrosive substances?

- Yes, a waterproofing membrane is typically resistant to saltwater and other corrosive substances. The membrane is designed to provide a protective barrier against moisture and chemicals, ensuring durability and preventing damage caused by corrosive elements.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Indeed, residential swimming pools can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction to safeguard against water infiltration and can be utilized on diverse surfaces including concrete, tile, and metal. By forming a barrier, they effectively prevent water from permeating the pool structure, thereby preserving its integrity and averting leaks. Furthermore, waterproofing membranes afford protection against other types of harm such as corrosion and deterioration resulting from chemicals or adverse weather conditions. Consequently, it is crucial to choose a top-notch waterproofing membrane specifically designed for swimming pool applications in order to guarantee long-lasting safeguarding and durability.

Send your message to us

PVC Roofing Waterproof Membrane/Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords