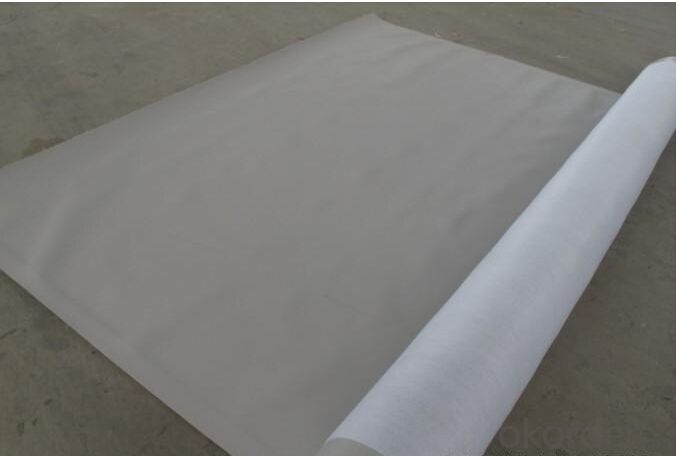

PVC Roofing and Waterproof Building Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

It is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti-aging agent, and stabilizer and other processing aids through extrusion and molding.

As the highly recommended product by the Ministry of Consturction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to weathering and root penetration and long service life.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Indeed, the utilization of a waterproofing membrane in tandem with fire protection systems is possible. Although the primary function of a waterproofing membrane is to prevent water infiltration, it can also serve as an additional safeguard against fire hazards. Numerous waterproofing membranes are engineered to possess fire-resistant qualities or exhibit fire-retardant characteristics. Consequently, they aid in impeding the spread of fire and minimizing its impact on the edifice. Furthermore, certain waterproofing membranes are specifically tailored for integration into fire protection systems, such as fire-rated roof membranes or fire-resistant sealants. These specialized membranes effectively seal off potential avenues for fire and establish a barrier to safeguard the underlying structure. In summary, the incorporation of a waterproofing membrane alongside fire protection systems contributes to the overall enhancement of a building's safety and security.

- Q: Are waterproofing membranes resistant to ammonia?

- Waterproofing membranes are generally resistant to ammonia. Ammonia is a chemical compound commonly found in cleaning agents and fertilizers, and it can be corrosive to certain materials. However, waterproofing membranes are specifically designed to withstand various chemicals and environmental conditions, including exposure to ammonia. These membranes are typically made from materials such as polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), or modified bitumen, which have excellent chemical resistance properties. Therefore, when properly installed, waterproofing membranes should be able to provide a barrier against ammonia and prevent its penetration into the underlying structures. It is important to note that the specific resistance of a waterproofing membrane to ammonia may vary depending on the type and quality of the membrane, as well as the concentration and duration of exposure. Hence, it is always recommended to consult the manufacturer's guidelines and perform compatibility testing before using any waterproofing membrane in an environment with ammonia presence.

- Q: Can a waterproofing membrane be used on tunnels with historical significance?

- Yes, a waterproofing membrane can be used on tunnels with historical significance. The membrane can help protect the tunnel from water damage and prevent further deterioration, ensuring the preservation of its historical significance.

- Q: Can a waterproofing membrane be used for a hospital basement?

- Yes, a waterproofing membrane can be used for a hospital basement. Waterproofing membranes are commonly used in various construction projects, including hospitals, to prevent water infiltration and protect the structure from moisture-related issues such as leaks, dampness, and mold growth. The basement of a hospital is particularly susceptible to water damage due to its below-grade location, making the use of a waterproofing membrane crucial. The membrane acts as a barrier against water seepage, effectively keeping the basement dry and preventing potential damage to the building and its contents. Additionally, a waterproofing membrane can help maintain a clean and safe environment in the hospital basement by preventing the growth of mold and other harmful microorganisms that thrive in moist conditions. Overall, the use of a waterproofing membrane in a hospital basement is highly recommended to ensure the structural integrity and safety of the building.

- Q: How do waterproofing membranes prevent water leakage?

- Waterproofing membranes function as a barrier between the surface and water, effectively preventing any leakage. These membranes, which can be made of bitumen, PVC, or EPDM, are typically applied in liquid or sheet form. The key mechanism by which waterproofing membranes halt water leakage is through the creation of a continuous and impermeable layer. This layer acts as a physical obstacle, preventing water from seeping through the surface. Moreover, the membranes are carefully applied to cover the entire surface, including joints, cracks, and seams, leaving no vulnerable areas for water penetration. Another important aspect of waterproofing membranes is their exceptional adhesive properties, enabling them to form a strong bond with the surface. This ensures that there are no gaps or spaces through which water can enter. Furthermore, by adhering firmly to the surface, the membranes also serve as a barrier against the movement of water vapor, effectively preventing moisture buildup and potential structural damage. Moreover, waterproofing membranes are specifically designed to offer high resistance to water and moisture. Their composition ensures that they do not degrade or deteriorate when exposed to water, guaranteeing their longevity and effectiveness. This resistance to water also prevents the membrane from becoming permeable over time. To sum up, waterproofing membranes effectively prevent water leakage by establishing a continuous and impermeable barrier on the surface. They cover the entire surface, adhere securely to eliminate gaps, and exhibit resilience against water and moisture. By implementing these measures, waterproofing membranes provide reliable protection against water infiltration and subsequent damage.

- Q: Can waterproofing membranes be used on precast concrete panels?

- Yes, waterproofing membranes can be used on precast concrete panels. These membranes are designed to provide an effective barrier against water penetration, protecting the concrete from moisture damage. They can be applied directly to the surface of precast concrete panels, ensuring their long-term durability and preventing water-related issues such as cracking, spalling, or corrosion.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. However, to ensure effective installation, it is important to properly prepare the surface by leveling or smoothing it out as much as possible before applying the membrane.

- Q: Can a waterproofing membrane be used for parking garages?

- Yes, a waterproofing membrane can be used for parking garages. A waterproofing membrane is a protective layer that is applied on surfaces to prevent water penetration. In parking garages, it is essential to have effective waterproofing to protect the structure from water damage, such as corrosion of steel reinforcement and deterioration of concrete. Parking garages are exposed to various sources of water, including rain, snow, and vehicle fluids, which can seep through cracks and joints. A waterproofing membrane acts as a barrier, preventing water from infiltrating the structure and causing damage. There are different types of waterproofing membranes available for parking garages, including sheet membranes, liquid-applied membranes, and cementitious coatings. These membranes can be applied on horizontal and vertical surfaces, such as floors, walls, and ramps, to create a watertight seal. When selecting a waterproofing membrane for a parking garage, factors such as durability, flexibility, and resistance to chemicals should be considered. The membrane should be able to withstand the heavy loads and traffic conditions typically found in parking garages. Overall, using a waterproofing membrane in parking garages is crucial to protect the structure and extend its lifespan by preventing water-related damage. It helps maintain the structural integrity and aesthetics of the garage while ensuring a safe and functional environment for users.

- Q: Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. Agricultural structures such as barns, greenhouses, and storage facilities often require protection from moisture and water damage. A waterproofing membrane is a durable and flexible material that can be applied to different surfaces such as roofs, walls, and floors to prevent water infiltration. It acts as a barrier, preventing water from seeping into the structure and causing damage to the building materials, equipment, and stored crops. Additionally, a waterproofing membrane can also help regulate the temperature and humidity levels within the agricultural structure, creating a more controlled and optimal environment for crops, livestock, and equipment. Overall, using a waterproofing membrane in agricultural structures can help ensure the longevity and functionality of the building while protecting the valuable assets inside.

- Q: How does a waterproofing membrane handle settlement cracks?

- A waterproofing membrane is designed to handle settlement cracks by providing a continuous and flexible barrier that prevents water penetration. Settlement cracks occur when the ground beneath a structure shifts or settles, causing the foundation to crack. These cracks can allow water to seep into the building, leading to moisture damage and potential structural issues. When a settlement crack occurs, a waterproofing membrane can be applied to the affected area to create a seamless and watertight seal. The membrane acts as a protective layer that prevents water from entering through the crack and migrating into the building. It also helps to maintain the structural integrity of the foundation by reducing the chances of further cracking and deterioration. The flexibility of the waterproofing membrane is crucial in handling settlement cracks. It can accommodate the movement of the underlying structure without compromising its performance. As the ground settles or shifts, the membrane stretches and contracts, ensuring that the crack remains sealed and the waterproofing system remains intact. Additionally, some waterproofing membranes are equipped with self-healing properties. This means that if a settlement crack does occur, the membrane has the ability to reseal itself to maintain its watertight integrity. This self-healing capability can minimize the need for frequent repairs and maintenance, saving time and costs for property owners. Overall, a waterproofing membrane is an effective solution for handling settlement cracks. It provides a durable and flexible barrier that prevents water infiltration, protects against further damage, and helps to preserve the longevity of the structure.

Send your message to us

PVC Roofing and Waterproof Building Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords