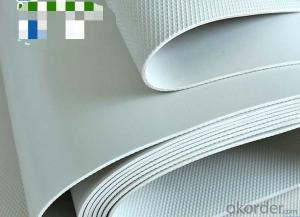

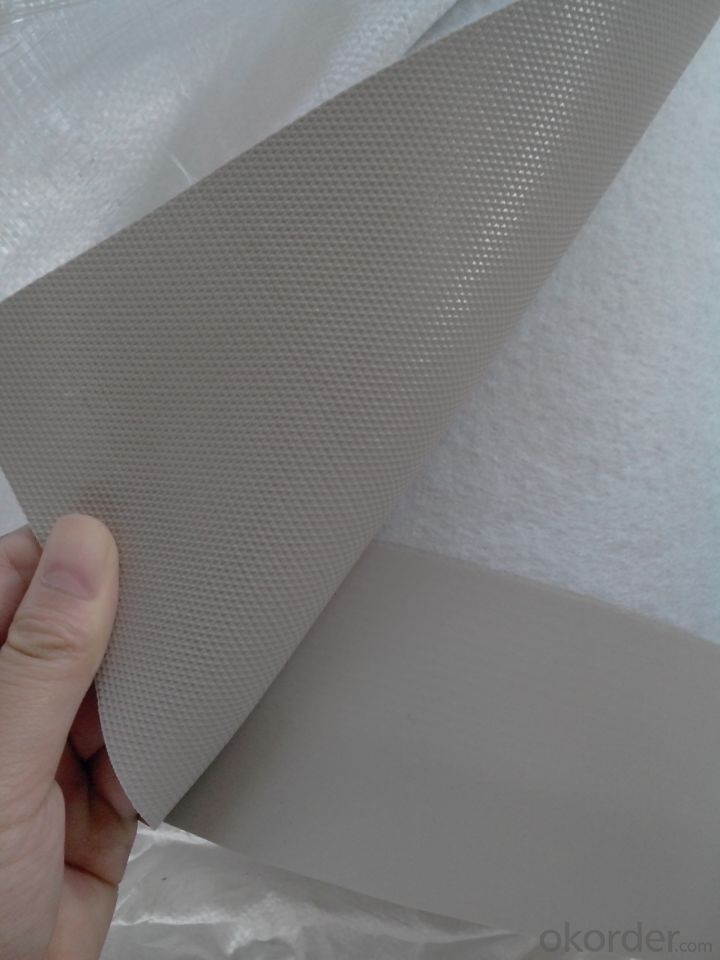

PVC Puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Brief introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane. The raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features and Benefits:

a) High Strength

b) Hot-air welded seams for long-term performance

c) Proven membrane performance

d) Excellent resistance to plasticizer extraction and migration performance.

Usage:

a) Roofing (covered & exposed roofs)/ Re- roofing

b) Tunnel Lining

c) Tanking of Underground structures

d) Lining of evaporation ponds & artificial lakes

e) Lining of drinking water tanks & swimming pools

f) Agricultural purposes & Lining of irrigation canals

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM (ethylene propylene diene terpolymer) is a highly durable and flexible synthetic rubber roofing material commonly used for low-slope and flat roofs. While EPDM roofs are already waterproof, applying an additional waterproofing membrane can provide an extra layer of protection and enhance the roof's longevity. The waterproofing membrane can act as a barrier against water infiltration, preventing leaks and moisture damage. However, it is important to ensure that the waterproofing membrane is compatible with EPDM and follows the manufacturer's guidelines for installation to maintain the roof's integrity.

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Yes, a waterproofing membrane is typically resistant to cracking and shrinking. The purpose of a waterproofing membrane is to create a barrier that prevents water from penetrating through surfaces, such as roofs, walls, or foundations. To achieve this, these membranes are usually made from flexible and durable materials, such as modified bitumen, PVC, EPDM, or polyurethane. These materials have inherent properties that allow them to withstand various environmental conditions, including temperature fluctuations, UV radiation, and physical stresses. This resilience ensures that the waterproofing membrane remains intact and stable, even when exposed to challenging conditions. Furthermore, waterproofing membranes are engineered to be highly resistant to cracking and shrinking. They are designed to accommodate movements and structural changes that may occur in the building or substrate over time. This flexibility helps to prevent the membrane from cracking or tearing, even if there are minor shifts or settling in the structure. Moreover, waterproofing membranes undergo rigorous testing and quality control measures during their manufacturing process to ensure their durability and resistance to cracking and shrinking. These tests simulate real-world conditions, including temperature changes, elongation, and compression, to verify the membrane's performance and longevity. However, it is important to note that the quality and performance of a waterproofing membrane can vary depending on the specific product and manufacturer. It is crucial to choose a reliable and reputable brand and ensure proper installation and maintenance to maximize the membrane's resistance to cracking or shrinking.

- Q: Polyethylene polypropylene waterproofing membrane forming. Secondary molding, what does it mean? How to distinguish?

- In the appearance and mechanical analysis, these two processes is difficult to distinguish, a composite also has poor quality, the second compound can also be done better. So, only in the approval of the production line, to control.

- Q: What is the difference between a liquid and sheet-type waterproofing membrane?

- A liquid waterproofing membrane is a coating that is applied in liquid form and then dries to create a protective layer. It can be applied using a brush, roller, or spray. On the other hand, a sheet-type waterproofing membrane is a pre-manufactured material made of rubber, PVC, or bitumen. It comes in large rolls or sheets and is usually installed by overlapping the sheets and adhering them to the surface using adhesives or heat. When it comes to installation, liquid waterproofing membranes are generally easier to apply because they can be molded and shaped to fit different surfaces and contours. They can also be applied to both horizontal and vertical surfaces without the need for seams or joints. Sheet-type membranes, however, require precise measurements and cutting to properly fit the surface. They also require more labor and time to install due to the need for overlapping and sealing the joints. In terms of flexibility, liquid membranes have better flexibility as they can conform to irregular surfaces and movements without cracking or tearing. Sheet-type membranes, while somewhat flexible, may not be able to adapt as well to surface movements or changes in temperature. Another difference is durability and lifespan. Sheet-type membranes are typically thicker and more robust, offering a longer lifespan and better resistance to punctures and mechanical damage. Liquid membranes, although effective for waterproofing, may not be as durable or long-lasting, particularly in high-traffic areas or areas prone to damage. When it comes to cost, liquid waterproofing membranes are generally more cost-effective compared to sheet-type membranes. They require less labor and materials for installation, making them a more budget-friendly option. However, it's important to consider the specific requirements and conditions of the project to determine the most suitable type of waterproofing membrane. Overall, the choice between a liquid and sheet-type waterproofing membrane depends on various factors such as the nature of the project, surface conditions, required flexibility and durability, and budget constraints.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Yes, a waterproofing membrane can be used in conjunction with paint or coatings. The membrane provides a barrier against water intrusion, while the paint or coatings provide additional protection and aesthetic appeal.

- Q: Can a waterproofing membrane be used on lead surfaces?

- Yes, a waterproofing membrane can be used on lead surfaces. Lead surfaces are often found in the roofing industry, and applying a waterproofing membrane can help protect against water damage and leaks. It is important to ensure that the waterproofing membrane is compatible with lead, as some membranes may react with or degrade the lead material. Additionally, proper surface preparation and installation techniques should be followed to ensure a secure and effective waterproofing solution. Consulting with a professional or manufacturer for specific product recommendations and installation guidelines is recommended.

- Q: How does a waterproofing membrane perform in areas with high temperature fluctuations?

- A waterproofing membrane performs well in areas with high temperature fluctuations due to its ability to withstand expansion and contraction without compromising its integrity. The membrane's flexibility and durability allow it to adapt to the changing temperatures, preventing cracks and leaks that could lead to water damage.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Indeed, geotechnical applications can make effective use of waterproofing membranes. These membranes are commonly employed to safeguard structures against water infiltration and are applied to various surfaces such as roofs, basements, and foundations. In geotechnical applications, these membranes serve the purpose of preventing water from seeping into the soil, thus averting erosion and stabilizing slopes. They can be positioned either horizontally or vertically to establish a barrier that hinders water penetration, which proves particularly advantageous in retaining walls, embankments, and dams. Furthermore, waterproofing membranes can be used to regulate water flow and enhance drainage in geotechnical projects. All in all, incorporating a waterproofing membrane into geotechnical applications can significantly enhance the longevity and performance of structures while effectively safeguarding them against water-related issues.

- Q: Modified asphalt waterproofing membrane SBS I G PE4 What does it mean?

- Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane

- Q: Can a waterproofing membrane be used for a hotel swimming pool area?

- Yes, a waterproofing membrane can be used for a hotel swimming pool area. A waterproofing membrane is a specially designed material that is applied to surfaces to prevent water penetration. It forms a protective barrier that prevents water from seeping into the underlying structure, protecting it from damage caused by water exposure. In the case of a hotel swimming pool area, a waterproofing membrane can be applied to the pool shell and surrounding areas to prevent water from leaking into the building or surrounding structures. This helps to maintain the integrity of the pool area and prevent any potential water damage. Additionally, a waterproofing membrane can also help to prevent the growth of mold and mildew, as it creates a moisture barrier. Therefore, using a waterproofing membrane for a hotel swimming pool area is a wise choice to ensure the longevity and durability of the pool and surrounding structures.

Send your message to us

PVC Puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords