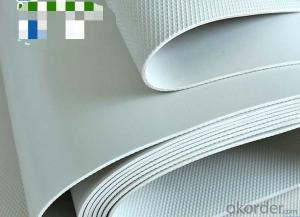

PVC Puncture Resistant Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Product Features

low -cost ,anti-aging ,anti -ultraviolet proformance ,shrinkage rate is high ,low temperature flexibility is good

Physical Property

1. Exposed to sunshine: UV rays resistance, long service life and aging resistance

2. Easy installation and dimensional stability: can be wieldable under wide range of temperature and experience minus dimensional change in thermal treatment

3. High tensile strength and elongation thus can accommodate movements of substrates

4.Good flexibility under low temperature, good adaptability to ambient temperature difference

5, Secure anti-puncture and good rooting resistance, no pollution caused to environment when being welded and good waterproofing choice for plant roofs

6. Good plasticity: convenient and fast treatment of detailed parts of corners and edges

Scope of Application:

1. The waterproofing of the Industrial or civil construction's roof, including the planting roof,

flat roof, sloping roof.

2. Waterproofing of the underground building: Including reservoirs, dams, canals, and all parts

of the basement water seepage.

3. Tunnel, granary, civil air defense projects, garbage landfills, and other man-made lake.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on precast steel surfaces?

- Indeed, precast steel surfaces can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to serve as a safeguard against water infiltration, making them suitable for various surfaces, including precast steel. By acting as a waterproof shield, the membrane effectively blocks water from penetrating the surface and causing any potential harm. It is imperative to ensure that the surface is adequately primed and sanitized prior to applying the membrane to ensure optimal adhesion and efficacy. Furthermore, seeking advice from a qualified waterproofing contractor is highly recommended in order to identify the most suitable membrane type and application technique for the specific precast steel surface.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Yes, a waterproofing membrane can be used on insulation surfaces. It provides an additional layer of protection to prevent moisture infiltration and damage to the insulation material.

- Q: SBs waterproof cold sticky how to do?

- 3, the node sealed processing. To be the primary treatment agent after drying, the first outlet, the root of the pipe and other vulnerable parts of the leakage, in the radius of 200mm range, even brush a layer of adhesive, brushing thickness of about 1mm is appropriate. Paste a layer of polyester fiber after the non-woven fabric, and in the non-woven cloth and then brushing a 1mm thick adhesive. After drying to form a layer of sealing layer.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Indeed, specific tools and equipment are indispensable when it comes to the installation of a waterproofing membrane. Some of the imperative tools and equipment that one must possess include: 1. Protective gear: To safeguard oneself from any detrimental chemicals or fumes, it is crucial to wear protective gear like gloves, goggles, and a face mask. 2. Cleaning equipment: Prior to the installation of the membrane, it is essential to have a clean and debris-free surface. Hence, one may require a broom, vacuum cleaner, or pressure washer to ensure thorough cleaning. 3. Waterproofing membrane: The appropriate type of membrane is contingent upon the project's requisites. It is vital to possess the right membrane material and sufficient coverage for a proper seal. 4. Primer: In certain cases, the utilization of a primer may be warranted to enhance adhesion between the surface and the membrane. The choice of primer is contingent upon the surface material and type of membrane being utilized. 5. Application tools: These tools are instrumental in the process of applying the membrane onto the surface. Brushes, rollers, or sprayers are some common application tools. The selection of tools is dependent on the type of membrane and the scale of the project. 6. Seam tape: If the waterproofing membrane necessitates seams, the presence of seam tape is vital to ensure an airtight seal at the joints. The tape must be compatible with the membrane material. 7. Adhesive or adhesive tape: Certain waterproofing membranes demand the utilization of adhesive for bonding them to the surface. Alternatively, adhesive tape can be employed for self-adhesive membranes. 8. Cutting tools: Based on the shape and size of the area to be waterproofed, one may require cutting tools such as utility knives or scissors to trim the membrane to the desired dimensions and shape. 9. Caulking gun: A caulking gun is an imperative tool for applying sealant or caulk to fill any gaps or cracks in the surface before the membrane installation. 10. Drying equipment: Following the installation of the membrane, a certain amount of time may be required for it to dry or cure. Depending on the specific membrane and environmental conditions, fans or dehumidifiers may be necessary to expedite the drying process. It is of utmost importance to refer to the manufacturer's guidelines or seek professional advice to ensure that all the necessary tools and equipment are available for a successful installation of the waterproofing membrane.

- Q: Are waterproofing membranes resistant to gasoline?

- Yes, waterproofing membranes are generally resistant to gasoline. Most waterproofing membranes are designed to be chemically resistant and can withstand exposure to various chemicals, including gasoline. However, it is important to note that the level of resistance can vary depending on the specific type of membrane and its composition. Some membranes may offer better resistance to gasoline than others. Additionally, prolonged exposure to gasoline can still potentially damage or degrade the membrane over time, so it is always recommended to take necessary precautions and avoid prolonged exposure to harsh chemicals.

- Q: Can a waterproofing membrane be used on brick walls?

- Yes, a waterproofing membrane can be used on brick walls. It helps to prevent water penetration and protects the bricks from moisture damage.

- Q: Is the foundation pit waterproofing and the foundation pouring on the working face?

- 2, your construction process is not clear: I tell you listen to the basic cushion after the completion of the construction, the cushion surface dryness to reach more than 90% can be done when the membrane waterproof layer, waterproofing membrane construction is completed, then do C20 40 ~ 50mm fine stone concrete protective layer, the construction is completed, generally the next day can be tied in the above bar.

- Q: What is the accounting subject of the waterproofing membrane

- Own spare, included in the project materials Waterproof sheet, used for sale, remember inventory goods

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

- Q: How does a waterproofing membrane handle expansion and contraction of the substrate?

- A waterproofing membrane is designed to accommodate the expansion and contraction of the substrate through its flexibility and elasticity. It can stretch and contract along with the movement of the substrate, ensuring a watertight seal is maintained without compromising its integrity.

Send your message to us

PVC Puncture Resistant Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords