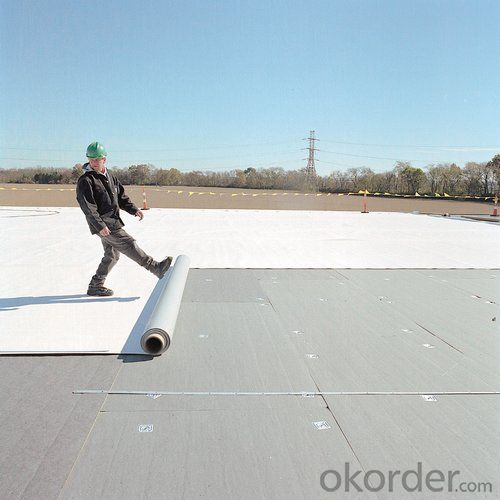

PVC Root Puncture Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

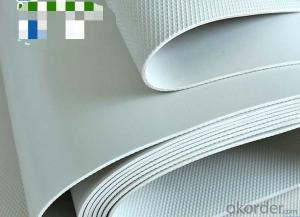

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Product Information

PVC roofing membrane is a highly-engineered,new-type membrane manufactured

using polyvinyl chloride as main materials and added other chemicals such as anti-oxidant,anti-UV materials to make it flexible,stable and UV-resistant.

Product Features

1. No pollution to the environment;

2. Fine tensile strength,elasticity,no deformation under hot or

cold temperature conditions;

3. Easily welding,firm and secure;re-weldable after weathering within their lifetime;

4. Fine resistance to static electricity;

5. Fine resistance to UV ;

6. Root-resistance and suitable for planting roofs;

7. Fine resistance to weathering and ageing;

8. Keep good flexibility under low temperature;

9. Fine puncture resistance,joint peel strength and joint shear strength property;

10. Easy treatments on delicate parts of corners and edges.

Application Range

PVC membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can waterproofing membranes be painted over?

- Painting over a waterproofing membrane is indeed possible. Nevertheless, it is crucial to verify the compatibility between the paint and the membrane material. It is advisable to refer to the manufacturer's guidelines or seek expert advice in order to guarantee the paint adheres well and lasts long. Furthermore, prior to applying the paint, the surface must be clean and dry to achieve optimal outcomes. All in all, painting over a waterproofing membrane can improve its aesthetic and offer extra safeguard against UV rays and other environmental elements.

- Q: Can a waterproofing membrane be used on roofs or only on vertical surfaces?

- A waterproofing membrane can be used on both roofs and vertical surfaces. It is a versatile solution that can effectively protect a variety of structures from water damage, including roofs, walls, and foundations.

- Q: Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to handle the expansion and contraction that occurs due to temperature fluctuations, making them ideal for protecting structures from water damage caused by thermal stress.

- Q: 3MM thick, one square meter waterproof membrane SBS price?

- 2, the asphalt or polymer waterproof material impregnated in the carcass, made of waterproof material products, in the form of coil, known as waterproofing membrane. According to the main composition of different materials, divided into asphalt waterproofing membrane, high polymer modified asphalt waterproofing membrane and synthetic polymer waterproofing membrane; according to the different carcass are divided into no carcass membrane, paper coil, glass fiber Tire Coil, Glass Fabric Coil and Polyethylene Tire Coil.

- Q: How does a waterproofing membrane compare to other waterproofing methods?

- A waterproofing membrane is highly effective in preventing water intrusion compared to other waterproofing methods. It forms a continuous barrier that is resistant to water penetration, protecting the underlying structure from moisture damage. Unlike other methods like sealants or coatings, a membrane offers superior durability and flexibility, ensuring long-term waterproofing performance. Additionally, membranes are easy to install and can cover large areas efficiently, making them a preferred choice in various construction projects.

- Q: Can a waterproofing membrane be used for an industrial facility?

- An industrial facility can utilize a waterproofing membrane. Such a membrane is a layer of protection that is applied to surfaces in order to prevent water from penetrating and causing moisture damage. Industrial facilities, including manufacturing plants, warehouses, and processing plants, often require effective waterproofing to safeguard their structures, equipment, and inventory against water damage. Industrial facilities commonly face exposure to various water sources, such as rain, leaks, or spills. Additionally, these facilities may experience high humidity levels or engage in water-intensive processes. By using waterproofing membranes, a reliable barrier against water intrusion can be established, thereby preventing damage and corrosion to the facility's structure, machinery, and products. Waterproofing membranes are designed to be durable and long-lasting, capable of withstanding harsh industrial conditions and heavy traffic or equipment. They come in different materials, such as bitumen, PVC, EPDM, or polyurethane, providing flexibility in selecting the most appropriate membrane for specific industrial applications. Moreover, waterproofing membranes offer additional advantages beyond water resistance. Certain membranes possess insulation properties, aiding in temperature regulation and reducing energy consumption. They can also enhance the overall safety and hygiene of an industrial facility by inhibiting the growth of mold, mildew, or bacteria that thrive in damp environments. To conclude, the utilization of a waterproofing membrane can prove highly effective in safeguarding an industrial facility from water damage. It establishes a dependable barrier against water intrusion, ensuring the facility's longevity and functionality while protecting valuable assets within it.

- Q: Can a waterproofing membrane be used in swimming pools?

- Yes, a waterproofing membrane can be used in swimming pools. These membranes are specifically designed to prevent water leakage and provide a durable and long-lasting waterproof seal. Using a waterproofing membrane in swimming pools helps to protect the structure from water damage and maintain the integrity of the pool's structure.

- Q: Can a waterproofing membrane be used for bridge decks?

- Yes, a waterproofing membrane can be used for bridge decks. Bridge decks are exposed to various weather conditions, including rain, snow, and humidity, which can cause damage and deterioration over time. Therefore, applying a waterproofing membrane on the bridge deck surface can help protect it from water infiltration and moisture-related issues such as corrosion of steel reinforcements. Waterproofing membranes are specifically designed to create a barrier that prevents water from penetrating the surface. They are typically made from materials such as modified bitumen, thermoplastic, or liquid-applied coatings. These membranes are applied to the bridge deck surface, creating a seamless and watertight layer that prevents water from seeping into the deck structure. In addition to preventing water infiltration, waterproofing membranes can also provide additional benefits for bridge decks. They can help reduce the risk of freeze-thaw damage, protect against chemical attacks from de-icing salts or pollutants, and increase the overall durability and lifespan of the bridge deck. It is important to note that the selection of the appropriate waterproofing membrane for a bridge deck depends on various factors such as the type of bridge, traffic conditions, climate, and expected service life. Therefore, it is essential to consult with structural engineers and waterproofing specialists to choose the most suitable membrane system for a specific bridge deck project.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Yes, a waterproofing membrane is typically resistant to UV radiation. This is because most waterproofing membranes are designed to withstand exposure to sunlight and other environmental factors, ensuring long-term durability and protection against UV radiation.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- A variety of surfaces, including concrete, wood, and metal, can benefit from the use of a waterproofing membrane. These membranes are designed to create a barrier that prevents water from causing damage by penetrating the surface. They are versatile and can adhere to different materials, making them suitable for various applications. For concrete surfaces, the application of a waterproofing membrane can protect against water intrusion and prevent issues such as cracks, corrosion, or mold growth. It is effective for concrete foundations, basements, or retaining walls, ensuring that they remain dry and structurally sound. When it comes to wood, a waterproofing membrane acts as a protective layer that prevents water absorption, warping, rotting, or decay. It is particularly useful for exterior surfaces like decks, balconies, or fences, as it enhances their lifespan and preserves their integrity. In the case of metal surfaces, a waterproofing membrane is capable of preventing rusting and corrosion caused by water exposure. By creating a barrier that seals out moisture, it protects metal roofs, gutters, or other metal structures from water damage. It is important to consider that different types of waterproofing membranes may be more suitable for specific surfaces. For instance, liquid-applied membranes are easily applied on irregular surfaces like concrete, while sheet membranes are more appropriate for flat or smooth surfaces. Consulting with a professional or manufacturer is advisable to determine the most suitable waterproofing membrane for a specific surface and application.

Send your message to us

PVC Root Puncture Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords