High Quality SBS Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

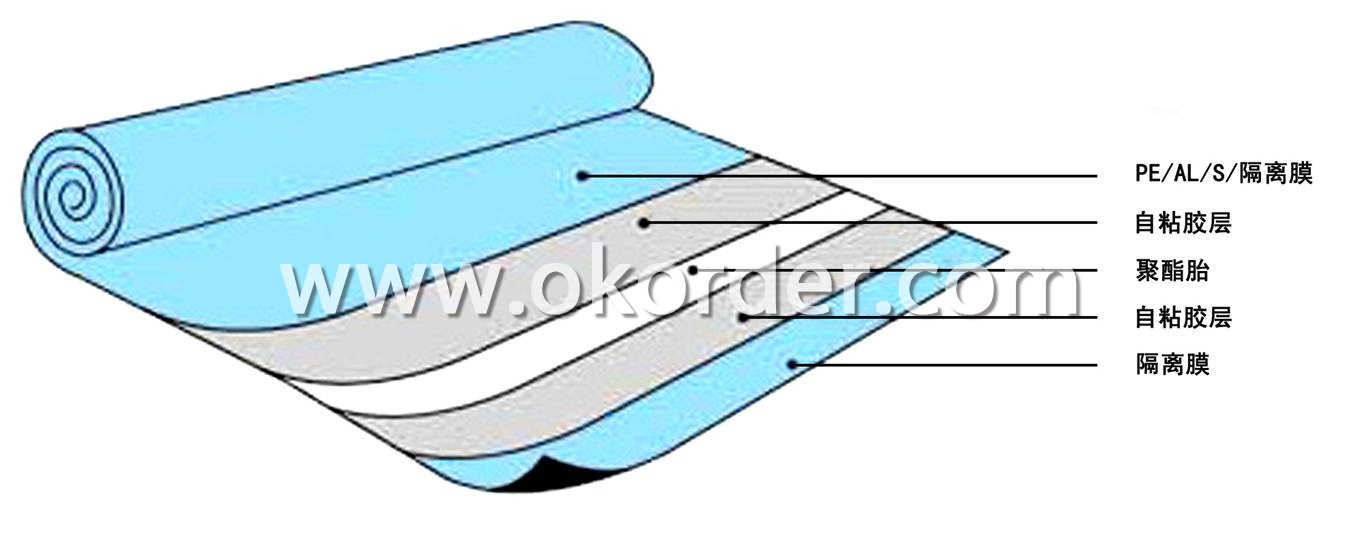

SBS modified bitumen waterproofing membrane is made by soaking the base in bitumen,or thermoplas ticityelastomer(such as styrene butadiene-SBS) modified bitumen, then covering double faces with elastomer(SBS) modified bitumen, and last finiishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

Characteristics Of SBS Waterproofing Membrane :

It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature;

Easy application , no pollution, and long service life etc.

Specification of SBS/APP Polyester Waterproofing Membrane:

|

N |

ITEM |

STANDARD |

TEST RESULT |

||

|

1

|

WATER IMPERMEABILITY |

PRESSUREMpa |

>0.3 |

NO IMPERAMEABILITY |

|

|

KEEPING TIME, min |

120MIN |

||||

|

2 |

TENSION N/5cm |

≥300 |

MEET ASTM-D5147 |

||

|

3 |

FRACTURE ELONGATION,% |

≥450 |

LONGTIUDINAL550.0 TRANSVERSE 510.0 |

||

|

4 |

SOFTEN POINT |

110°C, |

MEET ASTM-D 5147 |

||

|

5 |

COLD FLEXIBILITY |

≥0(-20) |

MEET ASTM-D 5147 |

||

|

6 |

ELONGATION |

≥45 |

47 |

||

|

7 |

APP/SBS WATERPROOF MEMBRANE MEET DEMAND OF ASTM STANDARD | ||||

Usage of SBS/APP Waterproofing Membrane :

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs, basements, toilets etc; and the waterproofing of bridges, parking area, tunnels, reservoir etc.

SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions while APP specially suitable to areas of high temperature and of strong sunshine.

- Q: Coil waterproof roofing requirements

- 4, the female wall to leave a waterproof membrane head groove, the height of the project after the completion of the requirements of more than 300 flood height, the general height of 400-500 is appropriate.

- Q: Can a waterproofing membrane be used on balconies and decks?

- Yes, a waterproofing membrane can be used on balconies and decks. Waterproofing membranes are specifically designed to provide a protective layer against water damage, making them an ideal solution for outdoor areas like balconies and decks that are exposed to rain, snow, and other moisture. By applying a waterproofing membrane, you can effectively prevent water penetration, enhance the durability of the surface, and extend the lifespan of your balcony or deck.

- Q: Can a waterproofing membrane be used for a commercial building?

- Yes, a waterproofing membrane can be used for a commercial building. Waterproofing membranes are specifically designed to protect structures from water damage. They are commonly used in various commercial applications such as roofs, basements, and foundation walls. The membrane acts as a barrier that prevents water from infiltrating the building, thus protecting it from potential leaks, moisture buildup, and mold growth. Additionally, waterproofing membranes are durable and can withstand harsh weather conditions, making them suitable for commercial buildings that are exposed to heavy rainfall or extreme temperatures. Overall, using a waterproofing membrane in a commercial building is an effective way to ensure long-term structural integrity and prevent costly water-related damage.

- Q: Can a waterproofing membrane be used for a rooftop garden protection?

- Yes, a waterproofing membrane can be used for rooftop garden protection. Waterproofing membranes are designed to create a barrier against water penetration, preventing leaks and protecting the underlying structure. By installing a waterproofing membrane on the rooftop, it helps to protect the garden and prevent water damage to the building.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help protect against mold or mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane creates a barrier that prevents water from seeping into the building structure. By keeping the area dry, it greatly reduces the chances of mold or mildew growth. Additionally, waterproofing membranes often have anti-microbial properties that inhibit the growth of mold and mildew even further. However, it's important to note that while a waterproofing membrane can provide significant protection against mold and mildew, it is not a foolproof solution. Proper ventilation and regular maintenance are also essential to prevent these issues.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. The membrane helps to prevent water ingress and moisture damage to the tunnel structure, ensuring the safety and longevity of the railway system.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting underground structures such as bunkers from moisture and water damage.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Preparation of the substrate is essential for the installation of a waterproofing membrane. Before applying the membrane, the surface on which it will be placed must be thoroughly cleaned, dried, and devoid of any contaminants or debris that could impede its adhesion. This process typically entails the removal of loose materials, such as old paint or sealants, and the leveling of any uneven surfaces. Furthermore, it may be necessary to repair any cracks or damage in the substrate to guarantee a proper and efficient installation of the waterproofing membrane. By following the recommended preparatory procedures, one can ensure that the membrane performs optimally and exhibits remarkable durability, effectively safeguarding the underlying structure against water infiltration.

- Q: Are waterproofing membranes resistant to chemical solvents?

- Waterproofing membranes are generally capable of withstanding chemical solvents. They are designed to endure exposure to different chemicals, including solvents. These membranes are formulated to create a barrier against moisture and safeguard against damage caused by chemical contact. The ability to resist chemical solvents is a crucial characteristic of waterproofing membranes, as it guarantees their durability and effectiveness in various applications like construction, roofing, and below-grade waterproofing. However, it is important to mention that the specific resistance of a waterproofing membrane to chemical solvents may differ based on the type and brand of membrane used. Therefore, it is always advisable to refer to the manufacturer's guidelines for detailed information on chemical resistance.

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- There is a variety of waterproofing membrane options available for above-ground and below-ground applications. When it comes to above-ground applications, structures like roofs, balconies, or walls require waterproofing. In these cases, commonly used membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand weather elements, such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable compared to above-ground membranes. Bituminous membranes, bentonite clay membranes, and composite membranes are commonly used options for below-ground waterproofing. Selecting the appropriate waterproofing membrane for each specific application is crucial due to varying requirements and challenges. Seeking advice from a waterproofing professional or engineer can assist in determining the most suitable membrane option for both above-ground and below-ground applications.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Europe; North America; Africa; Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6- 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100000 Square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

High Quality SBS Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords