PVC Root Puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

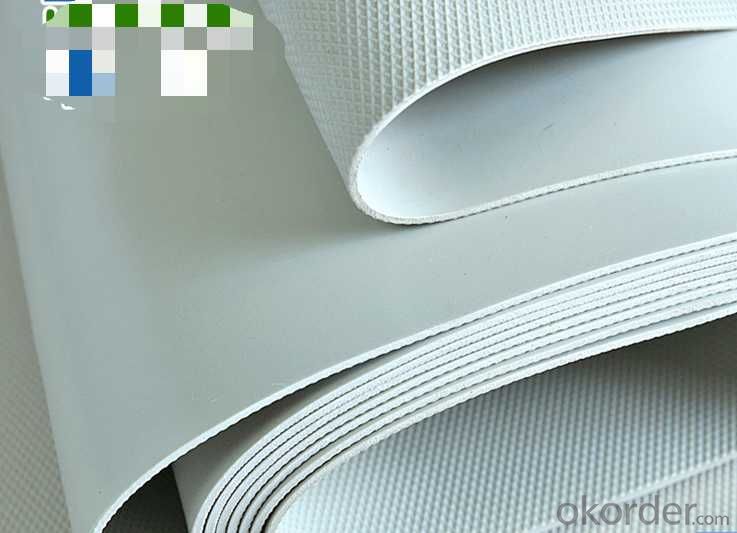

1.The structure of PVC Waterproofing Membrane Description:

PVC waterproofing membrane is a kind of high quality, high polymer waterproof sheet.PVC resin is joined processing agent, such as plasticizer, anti-uv agent, anti-aging agent, stabilizing agent.The polymer waterproofing material is manufactured by extrusion method. This product adopt with unique formula, product life far beyond the general of waterproof material, long service life, the whole waterproof system roof for more than 20 years, underground for more than 50 years, has been widely used in architecture, civil engineering.

2.Main Feature of PVC Waterproofing Membrane:

•Long service life,good ageing resistance.

•High tensile strength,high elongation.

•Good flexibility at low temperature,good root resistance permeability.

•Strong resistance to chemical corrosion,strong plasticity.

•Conveniente for construction,low price.

3.PVC Watrerproofing Membrane Specification:

| Name | Width | Thickness | Length | |

| PVC waterproofing membrane | 2m | 1.2mm | 20m | |

| 1.5mm | ||||

| 2mm | ||||

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can be used on rooftop terraces to protect them from water damage and ensure their longevity.

- Q: Can a waterproofing membrane be used in high-rise buildings?

- Yes, a waterproofing membrane can be used in high-rise buildings. In fact, it is highly recommended to incorporate a waterproofing system in high-rise buildings to protect them from the damaging effects of water infiltration. Waterproofing membranes are designed to provide a barrier against water ingress, preventing leaks and moisture damage to the structure. They are commonly used on roofs, basements, foundations, and other areas that are exposed to water or moisture. The selection of the appropriate waterproofing membrane will depend on various factors such as the specific building design, construction materials, and environmental conditions. It is important to consult with experienced waterproofing professionals to determine the most suitable membrane system for a high-rise building to ensure long-term protection against water-related issues.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Yes, a waterproofing membrane can be used in conjunction with paint or coatings. In fact, combining a waterproofing membrane with paint or coatings is a common practice in many construction and renovation projects. The waterproofing membrane provides a barrier against moisture and prevents water infiltration, while the paint or coatings add aesthetic appeal and can provide additional protection against UV rays, weathering, and chemical exposure. By using both in conjunction, you can achieve a dual-layer protection system that ensures long-lasting durability and water resistance. However, it is essential to ensure compatibility between the waterproofing membrane and the paint or coatings to avoid any adverse reactions or loss of effectiveness. Consult with a professional or manufacturer guidelines to determine the best combination and application process for your specific project.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Underground bunkers can utilize waterproofing membranes to great effect. Designed to establish a formidable defense against moisture, these membranes effectively thwart water infiltration into structures. This renders them an optimal solution for underground bunkers, which are susceptible to water encroachment due to their subterranean nature. By affixing a waterproofing membrane to the walls and floor of the bunker, it becomes possible to avert water seepage and maintain a dry interior. This is of paramount importance for safeguarding any stored items or occupants within the bunker. Moreover, waterproofing membranes offer additional advantages, such as insulation and protection against radon gas. It is crucial to select a membrane explicitly crafted for underground applications and capable of withstanding the unique conditions and pressures associated with subterranean environments.

- Q: How does a waterproofing membrane withstand temperature changes?

- A waterproofing membrane is designed to withstand temperature changes by being made from materials that can expand and contract without losing their properties. These materials are typically flexible and have a high tolerance for temperature fluctuations, allowing them to maintain their waterproofing capabilities even in extreme weather conditions. Additionally, the membrane's installation process often involves proper sealing and adhesion techniques, ensuring that it remains intact and unaffected by temperature changes.

- Q: Can a waterproofing membrane be used on precast concrete surfaces?

- Yes, a waterproofing membrane can be used on precast concrete surfaces. It helps to prevent water penetration and protect the concrete from moisture damage.

- Q: Can a waterproofing membrane be used for balconies and terraces?

- Yes, a waterproofing membrane can be used for balconies and terraces. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water penetration and damage. Balconies and terraces are exposed to outdoor elements such as rain, snow, and sunlight, which can cause moisture buildup and deterioration of the underlying structure. A waterproofing membrane acts as a barrier, preventing water from seeping through the surface and causing potential leaks, mold growth, or structural damage. It provides an effective solution to protect the balcony or terrace, ensuring its longevity and durability. Additionally, waterproofing membranes are available in different types and materials, allowing for flexibility in choosing the most suitable option based on the specific requirements of the balcony or terrace.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. Terraces and patios are exposed to various weather conditions, including rain and snow, which can lead to moisture seeping into the underlying structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the surface and protecting the integrity of the terrace or patio. It helps to extend the lifespan of the structure and prevents costly repairs in the long run. Additionally, using a waterproofing membrane also helps to create a more comfortable and usable space, as it eliminates the risk of water accumulation and potential slip hazards. Overall, investing in a high-quality waterproofing membrane is a wise decision for anyone looking to protect their terrace or patio from water damage.

- Q: Can waterproofing membranes be used on buried pipelines?

- Yes, waterproofing membranes can be used on buried pipelines. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and they can be applied to various surfaces, including buried pipelines. The membranes are typically made of materials such as bitumen or synthetic polymers, which are resistant to water penetration. When applied to buried pipelines, waterproofing membranes help prevent water infiltration, which can cause corrosion and deterioration of the pipeline material. They act as a barrier, preventing water from reaching the pipeline's surface and protecting it from potential damage caused by moisture. Additionally, waterproofing membranes also offer protection against other external factors, such as soil chemicals or gases, which can potentially cause harm to the pipeline. By creating a waterproof barrier, the membranes help extend the lifespan of buried pipelines, reduce maintenance costs, and improve overall performance. It is important to note that the selection and application of waterproofing membranes should be carried out by professionals who are knowledgeable in pipeline construction and waterproofing systems. Proper installation techniques and compatibility with the pipeline material are crucial to ensure the effectiveness of the waterproofing membranes.

- Q: Can a waterproofing membrane be used in parking garages?

- Parking garages can benefit greatly from the use of a waterproofing membrane. Due to their exposure to various weather conditions and heavy vehicular traffic, these structures are susceptible to moisture infiltration and structural damage. Therefore, it is crucial to install a dependable waterproofing system to safeguard against water penetration and potential deterioration. A waterproofing membrane serves as an effective solution for parking garages by acting as a barrier against water and moisture. It is typically composed of durable materials such as modified bitumen, PVC, or EPDM, which are resistant to water intrusion. When applied to the concrete surface, the membrane forms a protective layer that prevents water from seeping through. By preventing moisture from penetrating the concrete, the waterproofing membrane not only defends the parking garage against water infiltration but also helps to prolong its lifespan. This, in turn, reduces the risk of corrosion, deterioration of reinforcing steel, and the formation of cracks. Ultimately, the structural integrity of the parking garage is maintained, saving on costly future repairs or replacements. Moreover, a waterproofing membrane can offer additional advantages, including resistance to chemicals, UV radiation, and abrasion. This makes it an ideal solution for parking garages that face harsh environmental conditions and heavy traffic. To summarize, the use of a waterproofing membrane is highly recommended for parking garages. It provides reliable protection against water infiltration, helps to maintain the structure's integrity, and extends its lifespan.

Send your message to us

PVC Root Puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords