Waterproofing Atlanta

Waterproofing Atlanta Related Searches

Waterproofing Homes Waterproofing Wet Areas Residential Waterproofing Commercial Waterproofing Waterproofing Felt Roof Waterproof Material Waterproofing Concrete Floors Waterproofing Inspection Waterproof Sealer Concrete Slab Waterproofing Aquaseal Basement Waterproofing Waterproof Admixture Concrete Material Waterproofing Spray Waterproofing Concrete Block Walls Roofing Paper Waterproof Waterproof Seal Spray Waterproof Sealant Waterproof Thermal Blanket Exterior Foundation Waterproofing Materials Waterproof Concrete Blocks Waterproof Paint Waterproofing Company Names Waterproof Spray 303 Waterproofing Spray Soundproofing Homes Mel Rol Waterproofing Waterproof Paper Asphaltic Roofing Soundproofing Floors Plastomeric Waterproofing MaterialsWaterproofing Atlanta Supplier & Manufacturer from China

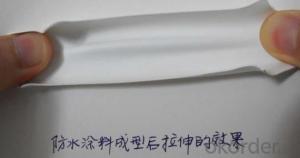

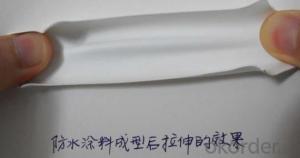

Waterproofing Atlanta offers a range of high-quality waterproofing products designed to protect structures from water damage. These products are essential for maintaining the integrity of buildings and infrastructure, ensuring that they remain safe and functional in the face of harsh weather conditions. Waterproofing Atlanta's products are widely used in various applications, including residential and commercial construction, as well as in the maintenance and repair of existing structures. The company's offerings cater to a diverse range of needs, making them a popular choice among contractors and homeowners alike.The waterproofing products from Waterproofing Atlanta are designed for use in a variety of scenarios, such as basement waterproofing, foundation repair, and the sealing of concrete cracks. These products are formulated to be effective against water infiltration, providing a robust barrier that prevents moisture from causing damage to the structure. Waterproofing Atlanta's products are also easy to apply, making them a convenient option for both professionals and DIY enthusiasts. By using Waterproofing Atlanta's products, property owners can rest assured that their buildings are well-protected against the ravages of water and weather.

Okorder.com is a leading wholesale supplier of Waterproofing Atlanta products, boasting a large inventory that caters to the needs of customers across various industries. As a trusted distributor, Okorder.com ensures that customers have access to a wide range of Waterproofing Atlanta's products, all of which are of the highest quality and backed by the company's reputation for excellence. By partnering with Okorder.com, customers can benefit from competitive pricing, fast shipping, and exceptional customer service, making it easier than ever to source the waterproofing products they need to protect their structures and investments.