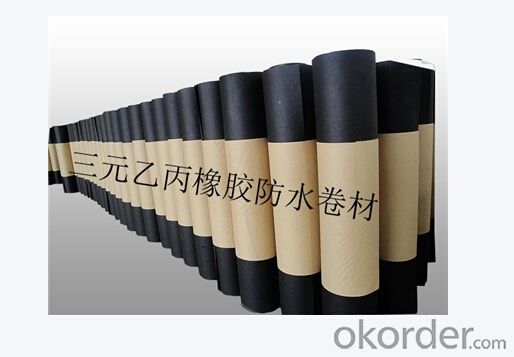

EPDM Waterproofing Rubber Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Dicription:

OKorder is offering high quality EPDM Rubber Waterproofing Membranes at great prices with worldwide shipping. Our supplier is a world-class manufacturer and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee a competitive price.

Product Applications:

OKorder's EPDM Rubber Waterproofing Membranes is ideal for roofs, basements, ponds, artificial lakes, steel structure roofs, swimming pools, subterranean construction, tunnels, etc.

Product Advantages:

OKorder's EPDM Rubber Waterproofing Membrane has been engineered with an extended service life to satisfy the demands of customers around the world.

Main Product Features:

· Excellent environmental stress, crack, aging, and corrosion resistance

· Extended service life

· Lowest permeability

· High elongation

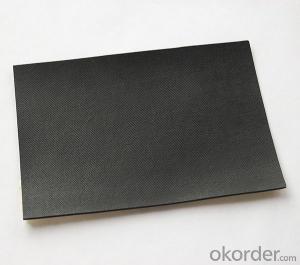

Product Specifications:

Name | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m (width) * 20m (length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced (homogeneous) | |||

Packing | 24 m² – 80m²/roll, with plastic bag | |||

Color | Black | |||

Number | Item | Unit | Value | |

1 | Size Variation | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Tensile Strength (Room Temperature) | Mpa | ≥7.5 | |

Tensile Strength (70°C) | Mpa | ≥2.3 | ||

3 | Elongation (Room Temperature) | % | ≥450 | |

Elongation (-20°C) | % | ≥200 | ||

4 | Tear Strength | KN/m | ≥25 | |

5 | Impermeability (30min) | * | 0.3Mpa no leakage | |

6 | Bending at Low Temperature | °C | ≤-40 | |

7 | Stretch Tension at Heat | Elongation | mm | ≤2 |

Shrinking | mm | ≤4 | ||

8 | Air Oven Aging (80°C x 168h) | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥70 | ||

9 | Anti-alkali | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥80 | ||

10 | During Manual Simulation | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥70 | ||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is waterproofing?

A3: Waterproofing products are designed to “prevent” water penetration even under wet conditions such as hydrostatic pressure in the soil after heavy rain storms or spring thaws. Waterproofing membranes stretch as the foundation settles and bridge small hairline settlement cracks that can occur in the concrete or block.

Images:

- Q: It is good for black roof with waterproof paper

- Roof waterproof selection is generally: SBS modified asphalt waterproofing membrane and self-adhesive waterproofing membrane.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Waterproofing membranes are commonly used in construction to prevent water infiltration and provide protection against moisture. In the case of underground communication vaults, where moisture and potential water leakage can be a concern, a waterproofing membrane can help ensure the integrity and longevity of the structure by creating a barrier against water intrusion.

- Q: Can a waterproofing membrane be tiled over?

- Yes, a waterproofing membrane can be tiled over. Tiling over a waterproofing membrane provides an additional layer of protection against water damage and helps create a durable and moisture-resistant surface.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Waterproofing membranes typically do not possess resistance against sulfuric acid exposure. Sulfuric acid, being an immensely corrosive substance, has the potential to inflict substantial harm to various materials, including waterproofing membranes. The membrane's deterioration can occur as a result of sulfuric acid's highly acidic properties, ultimately causing its failure. Hence, if there exists a chance of sulfuric acid exposure, it becomes crucial to employ materials that are explicitly engineered to endure such corrosive substances.

- Q: Can a waterproofing membrane be used in balconies or decks?

- Yes, a waterproofing membrane can be used in balconies or decks. Waterproofing membranes are specifically designed to prevent water penetration and protect underlying structures from moisture damage. Balconies and decks are often exposed to the elements, including rain and snow, which can lead to water damage and deterioration. By installing a waterproofing membrane, it creates a barrier that prevents water from seeping into the underlying structure, ensuring its longevity and durability. Additionally, waterproofing membranes can also protect against other forms of water damage, such as mold and mildew growth, which can be detrimental to the integrity of the balcony or deck. Overall, using a waterproofing membrane in balconies or decks is an effective solution to maintain their functionality and extend their lifespan.

- Q: Can a waterproofing membrane be installed on any surface?

- A waterproofing membrane can generally be installed on a variety of surfaces, but there are some factors to consider. The suitability of the surface depends on its condition, composition, and the type of waterproofing membrane being used. Typically, waterproofing membranes are designed to adhere to various substrates such as concrete, wood, metal, and masonry. They can be applied to surfaces like roofs, foundations, basements, bathrooms, and balconies. However, it is crucial to ensure that the surface is clean, dry, and free from any contaminants, such as dirt, debris, or loose materials, before installing the membrane. Furthermore, certain surfaces may require additional preparatory work or primers to enhance adhesion and ensure a long-lasting waterproofing solution. For example, rough or uneven surfaces might need to be leveled or smoothed out before the membrane can be applied. It is also important to consider the specific requirements of the waterproofing system being used. Different membranes have different application methods and compatibility with different surfaces. Some membranes may be more suitable for horizontal surfaces like flat roofs, while others may be better suited for vertical surfaces such as walls or foundations. Ultimately, it is recommended to consult with a professional waterproofing contractor or refer to the manufacturer's guidelines to determine the compatibility of the waterproofing membrane with a specific surface and to ensure proper installation for optimal performance and longevity.

- Q: Are waterproofing membranes suitable for residential applications?

- Indeed, residential applications can benefit greatly from the use of waterproofing membranes. These membranes find widespread use in a variety of residential construction areas, including basements, foundations, roofs, bathrooms, and balconies. Their primary purpose is to safeguard the building structure by preventing water penetration and moisture damage. Waterproofing membranes function as a barrier that effectively blocks water from infiltrating the structure, thereby averting problems such as mold growth, rot, or structural deterioration. These membranes commonly consist of materials such as bitumen, PVC, EPDM, or polyurethane, which possess exceptional water-repelling properties. During the construction or renovation process of residential buildings, waterproofing membranes are typically installed. They can be applied in the form of liquid coatings or sheets that are meticulously laid down and firmly affixed to the surface. These membranes create a seamless and long-lasting barrier that can withstand the test of time. Moreover, waterproofing membranes offer numerous advantages for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. As a result, they safeguard the integrity of the building materials, extend the lifespan of the structure, and minimize the likelihood of expensive repairs. Furthermore, these membranes contribute to enhanced energy efficiency by reducing heat loss or gain caused by moisture infiltration. By effectively blocking water, they assist in maintaining consistent temperatures inside the house, which leads to reduced energy consumption and lower utility bills. In conclusion, waterproofing membranes are an exceptional choice for residential applications. They provide dependable protection against water damage, enhance the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits. Elevator pits and sump pits are prone to water infiltration, and a waterproofing membrane can effectively prevent water from seeping into these areas. The membrane acts as a barrier, preventing any water from entering the pit and causing damage to the elevator or pumping system. This helps to maintain the integrity of the elevator or pump and prolong its lifespan. Additionally, a waterproofing membrane can also protect the surrounding structures and prevent any water damage. It is important to select a suitable waterproofing membrane that is designed for below-ground applications and has the necessary properties to withstand the specific conditions in an elevator or sump pit.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Yes, a waterproofing membrane can be used on rubber surfaces. Waterproofing membranes are designed to create a barrier that prevents water from penetrating and damaging the underlying surface. Rubber surfaces, such as roofs, decks, or even rubber flooring, can benefit from the application of a waterproofing membrane to protect them from water damage. The membrane is typically applied as a liquid or a sheet, and it adheres to the rubber surface, forming a protective layer that prevents water from seeping through. This can help to extend the lifespan of the rubber surface and prevent issues such as leaks or decay caused by moisture. However, it is important to ensure that the waterproofing membrane is compatible with rubber and the specific type of rubber surface being treated, as some membranes may not adhere properly or may cause damage to certain types of rubber. It is always recommended to consult with a professional or the manufacturer of the waterproofing membrane to ensure proper application and compatibility.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. Plant rooms and mechanical spaces are areas where equipment, machinery, or systems are installed, and they often contain pipes, tanks, or other components that require protection from water damage. A waterproofing membrane is a durable, flexible, and watertight barrier that can be applied to surfaces such as walls, floors, or ceilings to prevent water infiltration. By using a waterproofing membrane in plant rooms or mechanical spaces, you can ensure the longevity and functionality of the equipment and systems by protecting them from water leaks or moisture damage. Additionally, a waterproofing membrane can also provide a vapor barrier, preventing the buildup of condensation or humidity, which can be detrimental to sensitive equipment.

Send your message to us

EPDM Waterproofing Rubber Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords