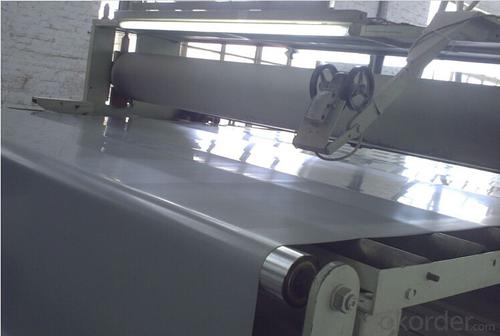

PVC Puncture Resistant Waterproof Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

name:High Quality PVC Waterproofing membrane

brand:Wanbao

width:2.05m

thickness: 1.2mm,,1.5mm,,2.0mm

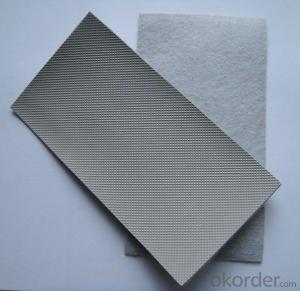

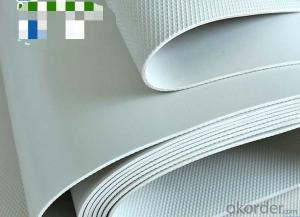

Product Features

low -cost ,anti-aging ,anti -ultraviolet proformance ,shrinkage rate is high ,low temperature flexibility is good

Physical Property

1. Exposed to sunshine: UV rays resistance, long service life and aging resistance

2. Easy installation and dimensional stability: can be wieldable under wide range of temperature and experience minus dimensional change in thermal treatment

3. High tensile strength and elongation thus can accommodate movements of substrates

4.Good flexibility under low temperature, good adaptability to ambient temperature difference

5, Secure anti-puncture and good rooting resistance, no pollution caused to environment when being welded and good waterproofing choice for plant roofs

6. Good plasticity: convenient and fast treatment of detailed parts of corners and edges

Product usage

Different kinds of Pvc waterproof membrane can variously be used to the roof building, underground building,tunnel,dam,pool,sewage treatment works,garbage disposal facilities.It also can be suitable to any requirement of all kinds of technological practice&different grade of roof waterproof and underground constructions waterproof.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Podium decks or plaza areas can benefit from the application of a waterproofing membrane. It is highly recommended to utilize this protective layer in order to safeguard the underlying structure from water-related harm. Given their exposure to the elements, podium decks and plaza areas are susceptible to water infiltration. By implementing a waterproofing membrane, water seepage into the lower layers can be effectively prevented, thus ensuring the long-lasting durability and structural integrity of the deck or plaza. Furthermore, this waterproofing membrane is also capable of shielding spaces beneath the deck or plaza, such as basements or parking garages, from potential water damage. Therefore, it is crucial to select a top-notch waterproofing membrane specifically designed for outdoor purposes, and to carefully adhere to the manufacturer's instructions regarding proper installation and maintenance.

- Q: Can a waterproofing membrane be used for exterior foundation walls?

- Yes, a waterproofing membrane can be used for exterior foundation walls. Waterproofing membranes are specifically designed to provide a barrier against water penetration and can be applied to the exterior surface of foundation walls to prevent moisture infiltration. This helps in protecting the foundation from potential damage caused by water, such as leaks, cracks, and deterioration.

- Q: Can a waterproofing membrane be used in high-traffic areas, such as decks or balconies?

- Yes, a waterproofing membrane can be used in high-traffic areas such as decks or balconies. Waterproofing membranes are designed to provide protection against water damage and can withstand regular foot traffic. They are durable and can effectively prevent water penetration, making them suitable for use in areas that experience heavy use.

- Q: Can a waterproofing membrane be used for a parking garage deck protection?

- Yes, a waterproofing membrane can be used for parking garage deck protection. A waterproofing membrane helps to prevent water infiltration, which can cause damage to the parking garage deck over time. It acts as a barrier, protecting the deck from moisture and extending its lifespan. Additionally, it can also help to minimize the risk of corrosion and deterioration of the underlying structure.

- Q: Can waterproofing membranes be used on swimming pool decks?

- Yes, waterproofing membranes can be used on swimming pool decks. Waterproofing membranes are designed to create a barrier against water penetration, making them an ideal solution for areas that are constantly exposed to water, such as swimming pool decks. By applying a waterproofing membrane to the deck surface, it helps to prevent any water from seeping through and causing damage to the underlying structure. Additionally, waterproofing membranes can also provide protection against chemicals, UV rays, and general wear and tear, which are common in swimming pool environments. Overall, using waterproofing membranes on swimming pool decks can help extend their lifespan, reduce maintenance costs, and enhance the overall safety and appearance of the area.

- Q: Can a waterproofing membrane be used in new construction?

- Yes, a waterproofing membrane can be used in new construction. In fact, it is often recommended to install a waterproofing membrane during the construction phase to provide an added layer of protection against water damage. Waterproofing membranes are typically applied to the exterior foundation walls and basement floors to prevent water infiltration and to create a barrier against moisture. This can help to prevent issues such as leaks, mold, and structural damage in the future. Additionally, waterproofing membranes can also be used in other areas of a new construction project, such as roofs, balconies, and bathrooms, to ensure long-lasting waterproofing protection. Overall, using a waterproofing membrane in new construction can help to prolong the lifespan of the building and provide peace of mind for the occupants.

- Q: Are waterproofing membranes resistant to soil chemicals?

- Yes, waterproofing membranes are typically resistant to soil chemicals. These membranes are designed to provide a barrier against water and moisture, and they are often made from materials that are resistant to various chemicals found in the soil. This resistance helps to protect the membrane from degradation or damage that could be caused by exposure to soil chemicals. Additionally, waterproofing membranes are often tested and certified to meet specific industry standards and regulations, which include resistance to soil chemicals. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the waterproofing membrane used. Therefore, it is crucial to select the appropriate membrane that is specifically designed to withstand the soil conditions and chemicals present in the project area. Consulting with a professional or manufacturer can provide further guidance on the best waterproofing membrane for a specific application.

- Q: Can a waterproofing membrane be applied to vertical surfaces?

- Vertical surfaces can indeed have a waterproofing membrane applied to them. In reality, waterproofing membranes are frequently utilized on vertical surfaces, like walls, foundations, and retaining walls, for the purpose of safeguarding against water infiltration. These membranes are specifically engineered to stick to vertical surfaces and create a protective barrier against water, thereby thwarting moisture from seeping into the structure. The process of application generally involves cleansing and preparing the surface, applying a primer if necessary, and then affixing the waterproofing membrane using an appropriate adhesive or mechanical fastening system. This guarantees that the membrane forms a continuous and secure seal, effectively preventing water from penetrating. In summary, waterproofing membranes provide an efficient solution for waterproofing vertical surfaces and are extensively employed in construction and building maintenance projects.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Certainly! Zinc surfaces can indeed benefit from the application of a waterproofing membrane. Zinc is widely used for its durability and resistance to corrosion, making it a popular choice for various purposes such as roofing and cladding. By adding a waterproofing membrane to zinc surfaces, an extra layer of protection against water intrusion and moisture damage can be achieved. This not only helps prevent leaks, but also extends the lifespan of the zinc surface and preserves its overall integrity. However, it is crucial to ensure that the chosen waterproofing membrane is compatible with zinc and specifically designed for such applications. To determine the most suitable waterproofing solution for zinc surfaces, it is advisable to seek professional advice or consult with the manufacturer.

- Q: Can waterproofing membranes be painted over?

- Painting over a waterproofing membrane is indeed possible. Nevertheless, it is crucial to verify the compatibility between the paint and the membrane material. It is advisable to refer to the manufacturer's guidelines or seek expert advice in order to guarantee the paint adheres well and lasts long. Furthermore, prior to applying the paint, the surface must be clean and dry to achieve optimal outcomes. All in all, painting over a waterproofing membrane can improve its aesthetic and offer extra safeguard against UV rays and other environmental elements.

Send your message to us

PVC Puncture Resistant Waterproof Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords