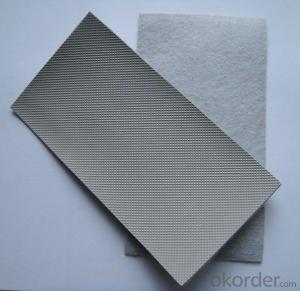

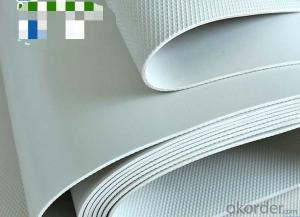

PVC Puncture Resistant Waterproofing Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Product Performance

1. Long life, anti-aging, roofing materials can be used more than 20 years, underground up to 50 years.

2. Tensile strength, high elongation, heat treatment of small size changes.

3. A good l ow temperature flexibility and adapt to environmental temperature change is good.

4. Resistance to root penetration, and can be made into green roofs.

5. Anti-perforation is good.

6. Convenient for construction, welding, solid and reliable and environmentally friendly non-polluting.

7. Resistance to chemical corrosion resistance, applicable to special occasions.

8. Has good plasticity, corner detail treatment convenient.

9. Easy maintenance and low cost.

Operation points

Generally, heat the jointing with the hot air or electric heating with hot air or welding by electricity. Waterproof construction of complex parts can be used matching PVC special accessories.

Technical Capacity Index (Ref to Chinese Standard GB12952-91)

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- EPDM roofs can benefit from the use of a waterproofing membrane. This synthetic rubber roofing material, known as EPDM, is popular for low-slope and flat roofs due to its durability and flexibility. Although EPDM roofs are already waterproof, adding a waterproofing membrane can offer an added layer of defense, increasing the roof's lifespan. By acting as a barrier against water infiltration, the waterproofing membrane prevents leaks and moisture-related harm. Nonetheless, it is crucial to guarantee that the chosen waterproofing membrane is compatible with EPDM and installed according to the manufacturer's instructions to preserve the roof's integrity.

- Q: Can a waterproofing membrane be used on chrome surfaces?

- No, a waterproofing membrane is not suitable for use on chrome surfaces as it is designed to be used on porous materials such as concrete or wood to prevent water penetration. Chrome surfaces are already water-resistant, so applying a waterproofing membrane would be unnecessary and may damage the chrome finish.

- Q: Can a waterproofing membrane be tiled over?

- Yes, a waterproofing membrane can be tiled over. Tiling over a waterproofing membrane provides an additional layer of protection against water damage and helps create a durable and moisture-resistant surface.

- Q: Are waterproofing membranes resistant to mineral oils?

- The resistance of waterproofing membranes to mineral oils can differ. Certain membranes are purposely engineered to withstand mineral oils, while others may not possess this capability. To ascertain the resistance level of a specific waterproofing membrane to mineral oils, it is crucial to review the manufacturer's specifications and product details. Moreover, seeking advice from a professional or directly contacting the manufacturer is advised to obtain tailored guidance regarding the compatibility of a waterproofing membrane with mineral oils in your unique scenario.

- Q: Can waterproofing membranes be used in basements?

- Basements can indeed benefit from the use of waterproofing membranes. These specialized membranes are designed specifically to act as a barrier against water penetration and are commonly employed in basements to effectively prevent moisture and water seepage. Typically composed of materials like rubber, bitumen, or polyethylene, these membranes are carefully applied to the walls and floors of the basement, creating an impermeable seal that keeps water out. By effectively stopping water from entering the basement, these membranes play a crucial role in safeguarding the foundation, walls, and interior spaces from the damaging effects of water, including mold and other moisture-related problems. Moreover, for comprehensive protection against water infiltration, waterproofing membranes can be utilized in conjunction with other waterproofing techniques like drainage systems and sump pumps.

- Q: Can a waterproofing membrane be used in historic buildings?

- Indeed, it is possible to utilize a waterproofing membrane in historic buildings. Given their age and construction materials, historic buildings frequently encounter challenges associated with moisture infiltration and water damage. To address this, waterproofing membranes offer a prevalent solution that prevents water seepage and safeguards the structural integrity of the building. Nonetheless, it is crucial to select a waterproofing membrane that is compatible with the materials and construction methods employed in the historic building to guarantee its preservation and adherence to historical authenticity. Moreover, any waterproofing work undertaken on a historic building should be carried out by professionals possessing expertise in historic preservation. This ensures proper installation and minimizes any adverse impact on the building's historical value.

- Q: Does a waterproofing membrane have any fire resistance properties?

- Generally, a waterproofing membrane does not possess any fire resistance properties. Its primary function is to create a barrier against water infiltration and safeguard the underlying structure from moisture-related harm. Conversely, fire resistance pertains to a material's capacity to endure fire or hinder the propagation of flames. Specialized fireproofing materials or coatings typically possess fire resistance properties and are specifically engineered to prevent fire spread and safeguard the structure during fire incidents. When choosing construction materials, it is crucial to consider both fire resistance and waterproofing prerequisites as they serve distinct purposes and may necessitate separate measures to ensure safety.

- Q: Are waterproofing membranes resistant to root penetration?

- Yes, waterproofing membranes are resistant to root penetration.

- Q: Does a waterproofing membrane require any specific curing time before it can be exposed to water?

- Before being exposed to water, a waterproofing membrane typically needs a specific amount of time to cure. This curing period is necessary for the membrane to fully bond and create a protective barrier against water infiltration. The length of time required may vary depending on the type of membrane and the instructions provided by the manufacturer. To guarantee the effectiveness and durability of the membrane, it is crucial to adhere to the recommended curing time. Premature exposure to water before the curing process is finished could compromise the membrane's performance, resulting in leaks or damage. Therefore, it is essential to follow the manufacturer's guidelines and allow the necessary curing time before subjecting the waterproofing membrane to water.

- Q: Can a waterproofing membrane be used for basements and crawl spaces?

- Yes, a waterproofing membrane can be used for basements and crawl spaces. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and moisture issues. A waterproofing membrane is a thin layer of material that is applied to the walls and floors of a basement or crawl space to create a barrier against water and moisture. This helps to keep the area dry and prevent water from seeping into the space, which can cause structural damage, mold growth, and other problems. Waterproofing membranes are designed to be durable and long-lasting, providing a reliable solution for protecting basements and crawl spaces from water intrusion.

Send your message to us

PVC Puncture Resistant Waterproofing Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords