EPDM Roof Waterproof Membrane with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

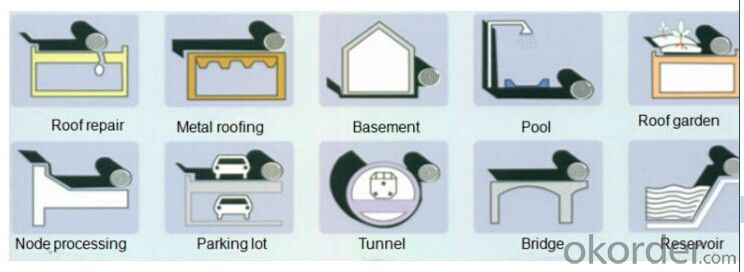

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in fountains or water features?

- Indeed, fountains and water features can benefit from the utilization of a waterproofing membrane. These specialized membranes are specifically crafted to safeguard surfaces against the infiltration of water, and their widespread adoption in construction projects, including fountains and water features, attests to their effectiveness. By establishing a formidable barrier, these membranes thwart any water seepage into the underlying structure, thereby guaranteeing the durability and operational functionality of the fountain or water feature. Furthermore, the versatility of waterproofing membranes is demonstrated by their compatibility with diverse materials such as concrete, stone, and metal, enabling their successful incorporation into a wide array of fountain designs and styles.

- Q: Can a waterproofing membrane be tiled over?

- Yes, a waterproofing membrane can be tiled over. Tiling over a waterproofing membrane provides an additional layer of protection against water damage and helps create a durable and moisture-resistant surface.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- The resistance of waterproofing membranes to chlorine exposure can vary. Certain membranes are designed to withstand chlorine and are commonly used in areas like pool decks or water treatment facilities where chlorine exposure is expected. These membranes are typically made with materials like PVC or TPO that naturally resist chlorine and can endure prolonged exposure without significant damage. It is important to be aware that not all waterproofing membranes are resistant to chlorine. Some membranes, particularly those made with materials like EPDM or bitumen, may not hold up as well against chlorine and may deteriorate or sustain damage with extended exposure. To ensure a waterproofing membrane lasts and performs well in a chlorine-rich environment, it is vital to choose a membrane specifically designed and tested for chlorine resistance. Seeking guidance from a waterproofing professional or manufacturer can assist in determining the most suitable membrane for the particular chlorine exposure conditions.

- Q: Can a waterproofing membrane be used in areas with chemical exposure?

- In areas where there is chemical exposure, it is possible to use a waterproofing membrane. However, it is vital to choose a waterproofing membrane that is specifically created to withstand chemical exposure. Not all waterproofing membranes are equal, and some may not be suitable for use in areas with chemical exposure. Waterproofing membranes that are resistant to chemicals are typically made from materials like polyurethane, epoxy, or polyurea, which are known for their ability to withstand various chemicals. These membranes are designed to act as a protective barrier against moisture and chemicals, preventing them from penetrating the underlying surfaces. When selecting a waterproofing membrane for areas with chemical exposure, it is crucial to consider the particular chemicals that will be present. Different chemicals can have varying effects on materials, so it is essential to choose a membrane that is specifically designed to resist the chemicals in the environment. It is recommended to consult with a professional or the manufacturer to ensure the appropriate selection of a chemical-resistant waterproofing membrane for the specific application.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Yes, a waterproofing membrane can be applied on top of existing surfaces. However, it is important to ensure that the existing surface is clean, dry, and in good condition before applying the membrane. Any cracks, holes, or damage should be repaired prior to installation. Additionally, the type of existing surface may affect the type of waterproofing membrane that can be applied. It is recommended to consult with a professional waterproofing contractor to determine the most suitable membrane for the specific surface and conditions.

- Q: Sbs waterproof sheet and app coil how to see it

- SBS full name is: styrene - butadiene - styrene block copolymer. SBS is an abbreviation of elastomer modified asphalt waterproofing membrane. It is also known as SBS modified asphalt waterproofing membrane. It is made of polyester felt, fiberglass felt or glass fiber reinforced polyester felt as the base, styrene-butadiene (SBS) thermoplastic elastomer as a petroleum asphalt modifier, both sides covered with isolation materials made of building waterproofing membrane, the product implementation of the standard GB18242 national mandatory standards. Product markings are carried out according to the following procedures: name, model, tire base, upper surface material, lower surface material, thickness, area and this standard number, for example: 3mm thick, 10㎡ area, the upper surface is mineral pellets, the lower surface is poly Vinyl film, polyester tread base, type I elastomer modified asphalt waterproofing membrane marked as: SBS I PY M PE 3 10 GB18242-2008.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Yes, a waterproofing membrane can be used for storage tanks or containment areas. Waterproofing membranes are designed to provide a barrier against water or other liquid penetration, making them suitable for applications where containment is required. These membranes are typically made from materials such as rubber, PVC, or bitumen, which are known for their water-resistant properties. They can be applied to the interior or exterior surfaces of storage tanks or containment areas to prevent leaks and protect the structures from moisture damage. Additionally, waterproofing membranes can also help to prevent the growth of mold or mildew, ensuring a safe and hygienic environment for stored materials or liquids.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas. Waterproofing membranes are typically used to protect structures from water damage, including roofs, basements, and decks. Stadium seating areas are often exposed to the elements, including rain and snow, which can lead to water damage if not properly protected. By applying a waterproofing membrane, the seating areas can be safeguarded against water infiltration, preventing potential issues such as mold growth, deterioration of materials, and structural damage. It is important to choose a high-quality waterproofing membrane that is specifically designed for outdoor use and can withstand heavy foot traffic, ensuring long-lasting protection for the stadium seating areas.

- Q: Can a waterproofing membrane be used on swimming pool decks?

- Yes, a waterproofing membrane can be used on swimming pool decks. Waterproofing membranes are designed to create a barrier against water penetration, making them ideal for protecting areas exposed to moisture, such as swimming pool decks. These membranes are typically applied to the surface of the deck, forming a seamless and durable waterproof layer. This helps prevent water from seeping into the deck, avoiding potential damage caused by moisture, such as cracking, mold growth, or structural deterioration. Additionally, waterproofing membranes can also provide added benefits, such as increasing the lifespan of the deck and improving its overall appearance.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- Classification: According to physical indicators are divided into: Ⅰ (-20 ℃), Ⅱ (-25 ℃) type two categories; According to the fetal base can be divided into: polyester tires, glass fiber tire two categories; according to the surface material can be divided Waterproof sheet

Send your message to us

EPDM Roof Waterproof Membrane with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords