Chinese Manufacturer Used In Roof PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The PVC waterproofing rolls formulas are based upon polyvinyl chloride resin with other assistants added to provide flexibility and stability such as anti-oxidant,absorbent of ultraviolet light, plasticizer and plastic filling agent.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

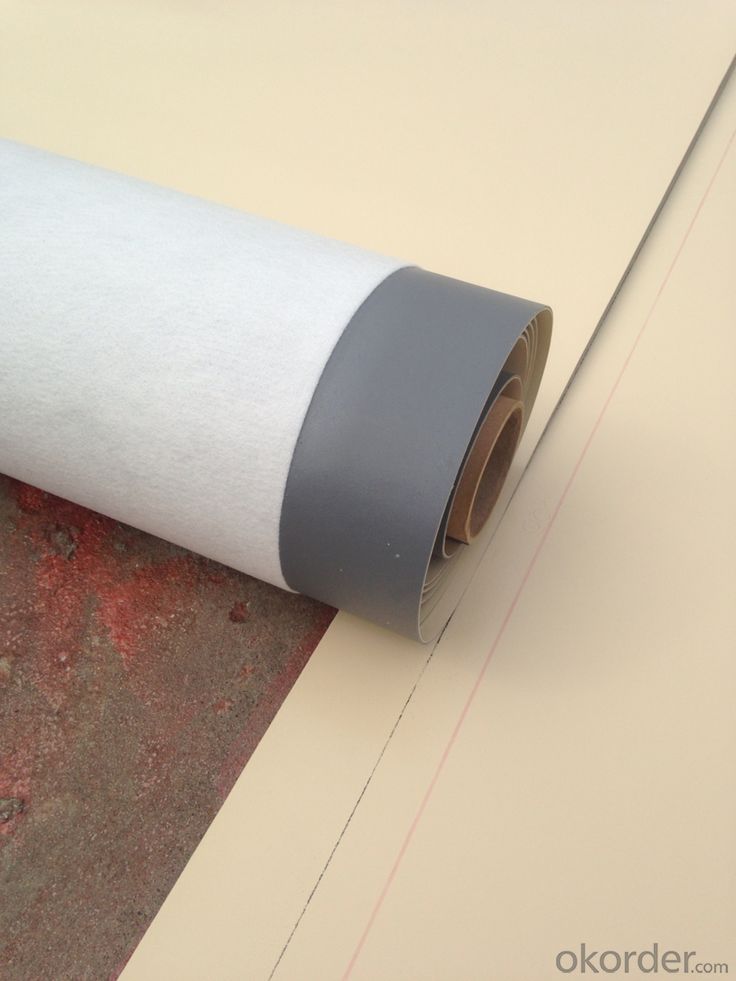

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on precast brick block surfaces?

- Precast brick block surfaces can indeed benefit from the application of a waterproofing membrane. Such a membrane serves as a protective shield, safeguarding the bricks against water infiltration, which could otherwise lead to undesirable consequences like cracks, efflorescence, or the growth of mold. It is crucial to select a waterproofing membrane explicitly designed for masonry surfaces, as these membranes are specially formulated to adhere perfectly to the distinct properties of brick and block materials. Moreover, to guarantee the membrane's effectiveness, it is essential to adhere to proper surface preparation and application techniques.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- Yes, there are several environmental considerations when using a waterproofing membrane. Firstly, the production and disposal of these membranes can have a negative impact on the environment due to the energy and resources required. Additionally, the chemicals used in some waterproofing membranes can be harmful to the environment and may leach into the soil or water systems. It is important to choose eco-friendly and sustainable options, such as those made from recycled materials or natural alternatives, to minimize the environmental impact. Regular maintenance and proper disposal of the membrane at the end of its life cycle are also crucial to ensure minimal harm to the environment.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Yes, a waterproofing membrane can be used for storage tanks or containment areas. Waterproofing membranes are designed to provide a barrier against water and moisture, making them suitable for preventing leaks and protecting the integrity of storage tanks or containment areas.

- Q: Can a waterproofing membrane be used on roofs with flat surfaces?

- Yes, a waterproofing membrane can be used on roofs with flat surfaces. Flat roofs are particularly prone to water damage, so a waterproofing membrane is a common solution to prevent leaks and protect the structure beneath. The membrane is applied to the roof surface to create a barrier that prevents water from seeping into the building.

- Q: Can a waterproofing membrane be used in combination with insulation materials?

- Yes, a waterproofing membrane can be used in combination with insulation materials. In fact, it is often recommended to use a waterproofing membrane in conjunction with insulation to protect the insulation from moisture damage and maintain its effectiveness. The waterproofing membrane forms a barrier that prevents water from reaching the insulation, ensuring its long-term performance.

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- Yes, there are different waterproofing membrane options available for above-ground and below-ground applications. Above-ground applications typically involve waterproofing structures such as roofs, balconies, or walls. For these applications, commonly used waterproofing membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand exposure to weather elements such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable than above-ground membranes. Commonly used below-ground waterproofing options include bituminous membranes, bentonite clay membranes, and composite membranes. It is important to choose the right waterproofing membrane for each specific application as the requirements and challenges can vary. Consulting with a waterproofing professional or engineer can help determine the most suitable membrane option for both above-ground and below-ground applications.

- Q: Is a waterproofing membrane resistant to UV rays?

- Yes, a waterproofing membrane can be resistant to UV rays. Many waterproofing membranes are designed and manufactured with additives that provide protection against UV rays. These additives help to prevent the membrane from degrading and losing its waterproofing properties when exposed to sunlight. UV resistance is an important feature in waterproofing membranes, especially for applications where the membrane will be exposed to direct sunlight for extended periods of time, such as on rooftops or outdoor structures. However, it is important to note that the level of UV resistance can vary depending on the specific type and brand of waterproofing membrane. Therefore, it is always recommended to check the product specifications and consult with the manufacturer to ensure that the chosen membrane offers the desired level of UV resistance for the intended application.

- Q: Modified asphalt waterproofing membrane SBS I G PE4 What does it mean?

- Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane

- Q: Can a waterproofing membrane be applied on top of existing coatings?

- Yes, a waterproofing membrane can be applied on top of existing coatings. However, it is essential to ensure that the existing coating is in good condition and properly adhered to the surface. Additionally, the compatibility between the existing coating and the waterproofing membrane should be checked to ensure proper adhesion and effectiveness. A professional evaluation is recommended to determine the suitability and compatibility of applying a waterproofing membrane over existing coatings.

- Q: Does a waterproofing membrane require a topcoat or sealer?

- Yes, a waterproofing membrane typically requires a topcoat or sealer to enhance its durability and provide additional protection against external elements such as UV radiation, abrasion, and chemical exposure. The topcoat or sealer helps to further seal the membrane and extend its lifespan, ensuring long-term waterproofing effectiveness.

Send your message to us

Chinese Manufacturer Used In Roof PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords