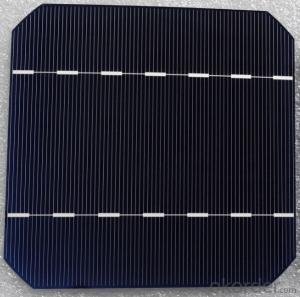

Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PV Solar Panel Price / Solar Cell / Solar Module

type:156M

appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

Product Show

Shipping

1. Shipment shall be made only after PAYMENT is received.

2. Please do inform us your DETAILED ADDRESS AND CONTACT INFOMATION before shipment.

3. Shipment shall be made in THREE WORKING DAYS.

- Q: What is the purity requirement for solar silicon wafers?

- The purity requirement for solar silicon wafers is extremely high, with a generally accepted standard of at least 99.9999% purity, or 6N purity. This level of purity ensures minimal impurities and defects in the silicon, maximizing the efficiency and performance of solar cells.

- Q: Are solar silicon wafers affected by UV radiation?

- Yes, solar silicon wafers are affected by UV radiation. While silicon is known to have a good resistance to UV radiation, prolonged exposure to high levels of UV radiation can cause degradation and reduced efficiency in solar silicon wafers. Therefore, it is important to consider the impact of UV radiation on solar panels and take necessary measures to protect and preserve their performance.

- Q: What are the different types of glass covers used on solar silicon wafers?

- There are typically two types of glass covers used on solar silicon wafers: tempered glass and anti-reflective coated glass. Tempered glass is a type of safety glass that is more durable and resistant to breakage. Anti-reflective coated glass, on the other hand, has a special coating that reduces reflection and increases light absorption, maximizing the efficiency of solar cells.

- Q: The higher the resistivity of silicon wafers, the better?!!! 1 experts please answer me!

- The resistivity is as narrow as possible, high resistance and low resistance can have high efficiency, is stable, easy to make a smooth PN junction in the diffusion resistance, high in the junction zone will less less complex, but more difficult to do the PN junction intact, low resistance lifetime will be shorter, but the PN junction will do very smooth, the higher resistivity is not the main, mainly has the corresponding process to match, want to have a stable process with stable resistivity.

- Q: What is the purpose of texturing the surface of a solar silicon wafer?

- The purpose of texturing the surface of a solar silicon wafer is to increase the efficiency of the solar cell by enhancing light absorption. Texturing creates a rough surface that reduces the amount of light reflected off the wafer, allowing more light to penetrate and be absorbed by the silicon. This improves the conversion of sunlight into electrical energy, resulting in higher solar cell efficiency.

- Q: What is the average weight of a solar silicon wafer?

- The average weight of a solar silicon wafer typically ranges from 2 to 4 grams, depending on the size and thickness of the wafer.

- Q: How does the efficiency of a solar silicon wafer change with cloud cover?

- The efficiency of a solar silicon wafer decreases with increasing cloud cover. Clouds block or scatter sunlight, reducing the amount of solar energy reaching the wafer. As a result, the wafer receives less sunlight to convert into electricity, leading to a decrease in its overall efficiency.

- Q: How do solar silicon wafers perform in high pollution areas?

- Solar silicon wafers generally perform well in high pollution areas, but excessive pollution can affect their efficiency and performance. Air pollution, specifically particulate matter and smog, can reduce the amount of sunlight reaching the wafers, resulting in decreased power output. Additionally, pollutants can settle on the surface of the wafers, reducing their ability to absorb sunlight effectively. Regular cleaning and maintenance can help mitigate these effects and ensure optimal performance in high pollution areas.

- Q: What does TTV mean in silicon wafer production?

- TTV is "total thickness variation" acronym or abbreviation, meaning total thickness variation, total thickness deviation.There is a method to measure the consistency of the thickness of silicon wafer, which is called the total thickness deviation (TTV)

- Q: Wafer cutting, NTC442 machine, a knife can cut how many pieces? How long is a piece of silicon?

- Do not stick stick with the United States and the United States, the line will be glued to the line together. With the kind of 3M model of the United States and rubber repair jumper glue will not stick on the line, if the jumper is too much can be inserted in the United States and the United States to close the line has been going to the end.

Send your message to us

Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords