Solar Silicon Wafer for Sale - High Quality A Grade Polycrystalline 5V 16.8% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

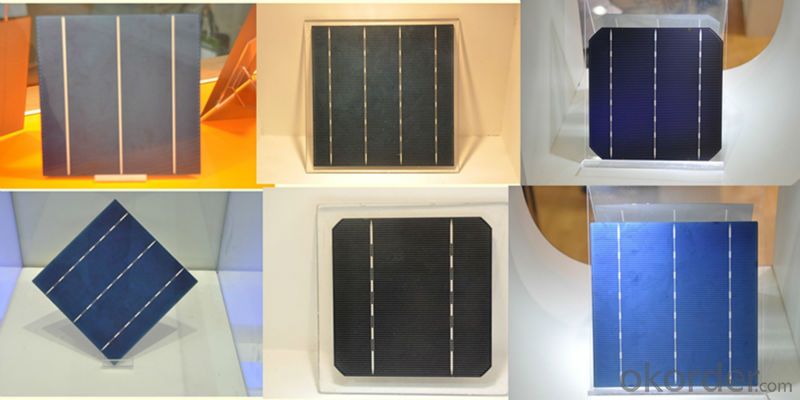

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

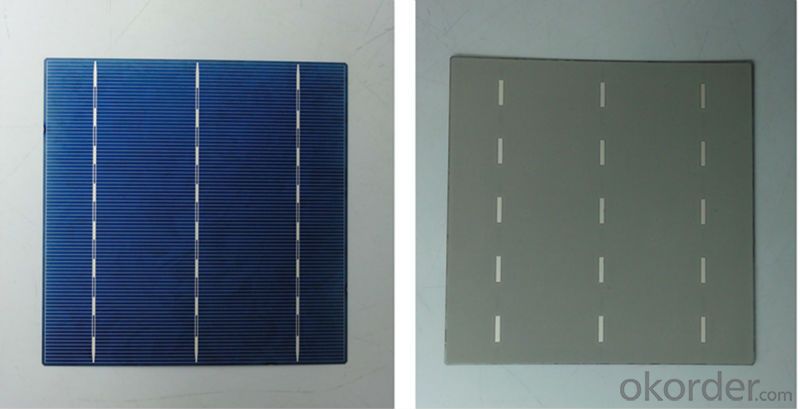

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: What is the role of grid lines on solar silicon wafers?

- The role of grid lines on solar silicon wafers is to facilitate the flow of electric current from the sun-exposed surface of the wafer to the electrical contacts. These grid lines act as pathways to collect and transport the generated electricity, improving the overall efficiency and performance of the solar cells.

- Q: How does the thickness of an anti-reflective coating affect the efficiency of a solar silicon wafer?

- The thickness of an anti-reflective coating on a solar silicon wafer affects its efficiency by reducing the amount of light reflection at the surface. A thicker coating can minimize reflection more effectively, allowing more light to be absorbed by the wafer and increasing the overall efficiency of the solar cell.

- Q: How are solar silicon wafers protected from electromagnetic interference?

- Solar silicon wafers are protected from electromagnetic interference through the use of specialized materials and shielding techniques. One common method involves encapsulating the wafers in a protective layer of non-conductive material, such as glass or plastic, which acts as a barrier against electromagnetic waves. Additionally, the solar cells are often housed within a metal frame or casing that further enhances the shielding effect. This combination of materials and design helps to minimize the impact of electromagnetic interference on the performance and efficiency of solar silicon wafers.

- Q: How are solar silicon wafers connected to form a solar cell?

- Solar silicon wafers are connected to form a solar cell by utilizing a process called soldering. The wafers are typically arranged in a grid-like pattern and then interconnected using metal contacts. These contacts are usually made of a conductive material, such as silver or copper, and are attached to the top and bottom surfaces of the wafers using soldering techniques. This interconnection allows the wafers to work together and convert sunlight into electricity efficiently.

- Q: How much energy is needed to produce a solar silicon wafer?

- The amount of energy required to produce a solar silicon wafer can vary depending on several factors such as the manufacturing process, technology used, and efficiency of the production facility. However, on average, it is estimated that around 250-350 kilowatt-hours (kWh) of energy are needed to manufacture one square meter of a standard silicon wafer for solar panels.

- Q: Are there any advancements in solar silicon wafer surface texturing techniques?

- Yes, there have been significant advancements in solar silicon wafer surface texturing techniques. Researchers have been exploring various innovative methods such as laser texturing, nanoimprinting, and chemical etching to enhance light absorption and overall efficiency of solar cells. These advancements aim to create highly textured surfaces that reduce reflection and increase the capture of sunlight, ultimately leading to improved performance of solar panels.

- Q: What is the role of a mounting structure in a solar silicon wafer?

- The role of a mounting structure in a solar silicon wafer is to provide support and stability to the wafer, allowing it to be securely attached to the solar panel or module. This structure ensures that the wafer remains in the correct position and orientation for optimal absorption of sunlight, maximizing the efficiency of the solar cell. It also helps protect the wafer from external forces such as wind, rain, and vibrations, ensuring its longevity and reliable performance.

- Q: How do solar silicon wafers perform in urban environments?

- Solar silicon wafers perform well in urban environments due to their ability to efficiently convert sunlight into electricity. However, certain factors such as shading from tall buildings and pollution can impact their performance. Overall, with proper installation and maintenance, solar silicon wafers can effectively generate renewable energy even in urban settings.

- Q: What is the efficiency of a solar panel made from solar silicon wafers?

- The efficiency of a solar panel made from solar silicon wafers can vary, but generally, it ranges from 15% to 20%.

- Q: Can solar silicon wafers be made flexible for applications in wearable devices?

- Yes, solar silicon wafers can be made flexible for applications in wearable devices. Advances in technology have allowed for the development of flexible solar cells that use thin-film materials instead of rigid silicon wafers. These flexible solar cells can be integrated into wearable devices, such as smartwatches or clothing, allowing them to generate power from sunlight while maintaining their flexibility and functionality.

Send your message to us

Solar Silicon Wafer for Sale - High Quality A Grade Polycrystalline 5V 16.8% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords