Prefabricated steel frame workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefabricated steel frame workshop warehouse building

Specification

1. Durable

2. Light Weight

3. Excelent quality

4. Atractive appearance

5.Easy and fast to install

6. Resistant 8-9 earthquake grade

7. Span life : over 50 years

8. Eco-friendly material: can be used for several times and can be recycled

| Name | Steel structure building | |

| Dimension | length | H beam 4000-15000 mm |

| thickness | web plate 6 -32 mm web plate 6 -40 mm | |

| height | 200 -1200 mm | |

| Color | avalible | |

| size | according to your requirement | |

| Advantages | 1. lower cost and beautiful outlook 2. high safty performance 3. easy to assemble and disassemble 4.installation with installation of experienced engineer 5. None -pollution | |

| Main componet | base | cement and steel foundation bolts |

| main frame | H beam | |

| material | Q 235 B , Q 345 B our main material | |

| purlin | C purlin or Z Purlin size from C 120 - 320 , Z 100 -20 | |

| bracing | X type or other type bracing made from angle and round pipe | |

| bolt | general bolt and high -strength bolts | |

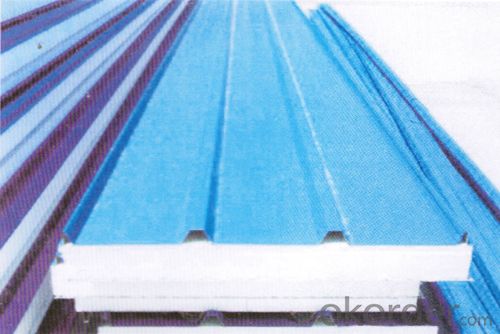

| roof & wall | sandwich panel and steel sheet | |

| door | sliding and rolling door | |

| window | plastic steel window | |

| surface | ||

| sheet | 0.35 -0.6 mm galvanized sheet | |

| accessories | semi - transparent skylight belts , ventilators , downpipe and galvanized gutter etc . | |

| Use | 1.workshop warehouse 2. steel web steel structure 3. steel H beam and H column 4. portal frame products 5. high rise project 6. other steel structure buildings | |

| Packing | main steel frame with 40 OT roof and panel load iin 40 HQ | |

| Drawing | Auto CAD , Sketchup , 3D ETC . | |

| Design parameter | If you would like to design for you , please offer us the following parameter : 1. length , width , height , eave height , roof pitch etc . 2. wind load , snow load , raining condition , aseismatic requirement etc . 3.demand for window and door 4.insulation material : sandwich panel ( thickness : 50 mm , 75mm , 100 mm etc ) and steel sheet . 5. crane : do you need the crane beam inside the steel structure and its capacity 6. other information if necessary | |

Fast construction metal shed sale with low cost

Why choose us

Specifications

fast building systems from china

1. high quality steel structure frame

2. low-price

3. easy to install

1. Why choose our building systems

1 More than 18 years’ experience

2 Light weight, high strength

3 Wide span: single span or multiple spans

4 Fast construction, easy installation and maintance

5 Low cost

6 Stable structure, earthquake proofing, water proofing, energy conserving and environmental protection

7 Long term service life: more than 50 years

2. Our building systems description

Our industral shed is an pre-engineered steel structure which is formed by the main steel framework linking up H section, Z section, and Csection steel components, roof and walls using a variety of panels. The steel workshop building is widely used for the large-scale workshop, warehouse, office building, steel shed, aircraft hangar etc.

- Q: What does HN350*175*7*11*16 represent in steel structures?

- HN350*175*7*11*16 in steel structure: H steel, 350mm high, 175mm wide, web thick 11mm, upper and lower plate thickness 16mm.

- Q: What are the considerations for designing steel structures for sound insulation?

- When designing steel structures for sound insulation, several considerations need to be taken into account. First and foremost, the choice of materials and construction methods should aim to minimize sound transmission through the structure. This may involve using sound-absorbing or sound-blocking materials, such as acoustic panels or insulation, to reduce the transfer of sound waves. Additionally, the design should consider the structural integrity of the steel components. Any joints or connections in the structure should be carefully designed to minimize the transmission of sound vibrations. The use of resilient mounts or isolators can help to isolate the steel elements from the surrounding structure, reducing the transfer of vibrations and consequently minimizing sound transmission. Furthermore, the layout and arrangement of the steel structure should be optimized to enhance sound insulation. This may involve incorporating features such as double walls or floors, as well as utilizing air gaps or insulation layers to create barriers against sound waves. Attention should also be given to the placement of openings, such as doors or windows, which can be potential weak points for sound transmission. Lastly, it is crucial to consider the specific requirements and regulations for sound insulation in the intended environment. Different settings, such as residential, commercial, or industrial, may have varying standards and guidelines that need to be met. Therefore, understanding and incorporating these requirements into the design process is essential to ensure effective sound insulation in steel structures.

- Q: How are steel structures designed for different retail systems?

- Steel structures for different retail systems are designed based on the specific requirements and functions of each retail system. Factors such as the size and layout of the retail space, the type and weight of merchandise, and the number of floors or levels are taken into consideration. The design takes into account the load-bearing capacity of the steel structure to ensure it can support the weight of the building, as well as withstand any potential environmental hazards. Additionally, the design process may involve considering factors like cost, aesthetics, and flexibility for potential future expansions or modifications.

- Q: How are steel structures designed for seismic loads?

- Steel structures are designed for seismic loads by considering several key factors. First, the design takes into account the specific location and expected level of seismic activity in that area. This information helps engineers determine the appropriate design criteria and seismic loadings to be applied. Next, the structural system and framing layout are carefully chosen to provide optimal resistance to seismic forces. Steel frames are commonly used due to their inherent strength and ductility, which allows them to absorb and dissipate energy during an earthquake. The design also incorporates various structural elements like bracing, shear walls, and dampers to enhance the building's ability to withstand seismic forces. Moreover, the connections between steel members are designed with special attention to detail. These connections are designed to be strong and flexible, allowing for some movement and deformation during an earthquake without compromising the overall stability of the structure. Lastly, rigorous analysis and testing methods, such as computer simulations and physical shake table tests, are employed to verify the structural performance under seismic loads. These analyses help engineers refine the design and ensure that the structure can withstand the anticipated seismic forces, ensuring the safety of occupants and minimizing damage during an earthquake.

- Q: What are the different types of steel structures?

- There are several different types of steel structures, including steel frame structures, steel truss structures, steel beam structures, and steel arch structures. Each type has its own unique design and construction methods, making them suitable for various applications such as buildings, bridges, and industrial facilities.

- Q: How are steel structures designed to be resistant to impact and blast loads?

- Steel structures can be designed to be highly resistant to impact and blast loads through various measures. Firstly, the design process incorporates a thorough understanding of the expected impact or blast loads. This includes analyzing the potential sources of impact or blast, such as explosions, collisions, or falling objects, and determining the magnitude, direction, and duration of the loads. To enhance resistance against impact and blast loads, several design strategies are employed. These include: 1. Material selection: High-strength steel alloys with superior mechanical properties are chosen to ensure structural integrity under extreme loads. These materials have excellent ductility, toughness, and fatigue resistance, making them more resistant to deformation and failure. 2. Structural redundancy: The design incorporates redundant members and connections to distribute the impact or blast loads throughout the structure. This redundancy helps to prevent localized failures and ensures that the structure can still carry the loads even if certain elements are damaged. 3. Progressive collapse prevention: Progressive collapse refers to the failure of a primary structural element resulting in the collapse of the entire structure. To prevent this, steel structures are designed with alternate load paths, such as secondary beams and columns, to redirect the forces in case of a local failure. This ensures that the structure remains stable and can withstand the impact or blast loads. 4. Blast-resistant design details: Specific design details are implemented to enhance resistance against blast loads. These include minimizing the size and number of openings in the structure, using blast-resistant glazing systems, and incorporating sacrificial elements that absorb and dissipate the blast energy. 5. Reinforced connections: Connections between structural members are critical for withstanding impact and blast loads. Special attention is given to the design of these connections, including the use of high-strength bolts, welding techniques, and additional reinforcement, such as stiffeners or plates, to improve their resistance to dynamic loads. 6. Blast-resistant coatings: The application of blast-resistant coatings on the structural elements can enhance their resistance to blast loads. These coatings are designed to absorb and dissipate energy, reducing the transmitted forces and protecting the underlying steel from damage. 7. Dynamic analysis: Advanced computer simulations and finite element analysis techniques are utilized to evaluate the response of steel structures to impact and blast loads. These analyses help to identify potential areas of weakness, optimize the design, and ensure that the structure can withstand the expected loads. By incorporating these design strategies, steel structures can be highly resistant to impact and blast loads. This resistance is crucial for safeguarding buildings and infrastructure against potential threats, ensuring the safety and security of occupants and assets.

- Q: What are the factors to consider when selecting steel for a structure?

- When selecting steel for a structure, there are several factors to consider. These include the desired strength and durability of the steel, the anticipated load or weight that the structure will bear, the environmental conditions the structure will be exposed to (such as moisture, temperature variations, or corrosive elements), the required fire resistance, as well as the cost and availability of the steel. Additionally, factors like the design flexibility, ease of fabrication, and the potential for future modifications or expansions should also be taken into account.

- Q: What are the typical design considerations for steel warehouses or distribution centers?

- Some typical design considerations for steel warehouses or distribution centers include structural integrity to support heavy loads, efficient space utilization, proper ventilation and lighting, fire safety measures, accessibility for loading and unloading operations, and flexibility for future expansion or reconfiguration. Additionally, factors like cost-effectiveness, sustainability, and compliance with building codes and regulations are also important considerations in the design process.

- Q: What are the considerations for designing steel structures for healthcare facilities?

- When designing steel structures for healthcare facilities, several considerations need to be taken into account. Firstly, the building should be able to withstand the loads and stresses associated with the equipment and services required in a healthcare setting. This includes accounting for the weight of medical equipment, patient beds, and various mechanical systems. Secondly, the design should prioritize the safety and well-being of patients, staff, and visitors. Steel structures should be able to withstand seismic forces and provide adequate fire resistance to protect occupants. Additionally, the layout and design should facilitate efficient and safe movement of patients and staff throughout the facility, considering factors such as patient privacy and accessibility. Another important consideration is the flexibility and adaptability of the steel structure. Healthcare facilities often undergo changes and expansions over time, so the design should allow for easy modifications without compromising structural integrity or functionality. Lastly, sustainable design practices should be incorporated into the steel structure design. This includes using environmentally friendly materials, optimizing energy efficiency, and integrating natural lighting and ventilation systems to create a healthy and sustainable environment for both patients and staff. Overall, designing steel structures for healthcare facilities requires careful attention to structural integrity, safety, flexibility, and sustainability to create functional and resilient spaces that support the delivery of quality healthcare services.

- Q: What is the process of demolishing a steel structure?

- The process of demolishing a steel structure typically involves several steps. First, a thorough inspection of the structure is conducted to identify any hazardous materials, such as asbestos or lead, that may need to be properly handled and removed before demolition. Next, a demolition plan is developed, considering factors like the size and complexity of the structure, nearby structures, and safety precautions. Once preparations are complete, the actual demolition begins. This can involve various methods, including using heavy machinery like excavators or cranes to dismantle the structure piece by piece, or using explosives to bring down the entire structure in a controlled manner. Care must be taken to ensure the safety of workers and the surrounding environment during the demolition process. After the structure is demolished, the debris and remaining materials are typically sorted and recycled, if possible, to minimize waste and environmental impact. Finally, the site is cleaned and restored, ensuring that any remaining hazards are properly addressed.

Send your message to us

Prefabricated steel frame workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords