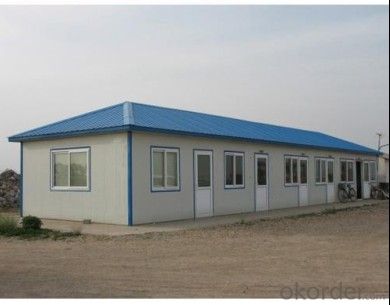

steel structure workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Steel structure workshop warehouse building

1. ISO9001:2008, SGS and BV Certification

2. Structural safety and reliability

steel structure workshop warehouse building

Technical Parameters

Item Name | steel structure workshop warehouse building |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement | |

(size by length/width/height and wind speed), offering a free design | |

drawing and all detailed drawings for installation. | |

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

Packaging Detail:According to container size,container of 20 feet:Inside capacity is 5.69m x 2.34m x 2.18m,Gross weight of allocation is generally 17.5 ton,volumn is 24-26m3. container of 40 feet:Inside capacity is 11.8m x 2.34m x 2.18m,Gross weight of allocation is generally 22 ton,volumn is 54m3. HC container of 45 feet:Inside capacity is 13.58m x 2.34m x 2.71m,Gross weight of allocation is generally 29 ton,volumn is 86m3.Delivery Detail:30 days.

- Q: Can steel structures be designed to be resistant to corrosion from saltwater?

- Yes, steel structures can be designed to be resistant to corrosion from saltwater. Specialized coatings such as galvanization or corrosion-resistant paint can be applied to steel surfaces to protect them from the corrosive effects of saltwater. Additionally, stainless steel or other alloy steels with high levels of chromium or nickel can be used, as they have inherent resistance to corrosion in saltwater environments. Proper maintenance and regular inspections are also important to ensure the long-term durability and corrosion resistance of steel structures in saltwater conditions.

- Q: What are the considerations for designing steel structures for energy-efficient performance?

- There are several considerations to keep in mind when designing steel structures for energy-efficient performance. First and foremost, it is important to optimize the building's envelope by incorporating proper insulation, air sealing, and efficient glazing systems. This helps to minimize heat loss or gain and improve overall energy efficiency. Additionally, the design should focus on utilizing natural lighting and ventilation strategies to reduce the reliance on artificial lighting and mechanical ventilation systems. This can be achieved through thoughtful placement of windows, skylights, and louvers to maximize daylighting and natural airflow. Furthermore, the selection of materials and construction techniques should prioritize sustainability and resource efficiency. Using recycled or locally sourced steel, as well as incorporating renewable energy systems like solar panels, can help reduce the environmental impact of the structure. Lastly, incorporating smart building technologies and energy management systems can further enhance energy efficiency by enabling real-time monitoring, control, and optimization of energy usage. Overall, through a holistic approach that encompasses insulation, natural lighting and ventilation, sustainable materials, and smart technologies, steel structures can be designed to achieve optimal energy-efficient performance.

- Q: What is the role of steel canopies in a residential structure?

- The role of steel canopies in a residential structure is to provide protection and shelter from the elements, such as rain or sun, while also adding aesthetic value to the overall design. They serve as a functional and decorative element, enhancing the outdoor space and providing shade and cover for entryways, patios, or outdoor living areas. Additionally, steel canopies offer durability and strength, ensuring long-lasting protection and support for the structure.

- Q: What are the design considerations for steel structures in seismic retrofit projects?

- Design considerations for steel structures in seismic retrofit projects include: 1. Seismic forces: The steel structure needs to be designed to withstand the potential seismic forces that can occur during an earthquake. This involves analyzing the expected ground motion and determining the appropriate design parameters, such as the design acceleration and response spectrum. 2. Structural capacity: The existing steel structure needs to be assessed for its current capacity and potential deficiencies. This evaluation helps determine if additional reinforcement or strengthening measures are required to ensure the structure can withstand the seismic forces. 3. Ductility and energy dissipation: Steel structures should be designed to have sufficient ductility, which is the ability to deform without sudden failure. This allows the structure to absorb and dissipate energy during an earthquake, reducing the potential for damage. This may involve adding supplemental steel braces or dampers to enhance the structure's ability to absorb seismic energy. 4. Connection design: The connections between steel members play a critical role in the overall behavior of the structure during an earthquake. Proper connection design is crucial to ensure that they can accommodate the expected seismic forces and maintain the integrity of the structure. 5. Retrofit techniques: Various retrofit techniques can be employed for steel structures, such as adding steel bracing, installing steel plate shear walls, or using external post-tensioning systems. The selection of the most suitable retrofit technique depends on the specific requirements and constraints of the project. 6. Code compliance: All design considerations for steel structures in seismic retrofit projects should comply with the relevant building codes and standards. These codes provide guidelines and requirements for seismic design and retrofitting, ensuring the safety and performance of the structure during earthquakes.

- Q: What are the different types of steel framing systems?

- There are several different types of steel framing systems, including light gauge steel framing, structural steel framing, and cold-formed steel framing. Light gauge steel framing is commonly used in residential and commercial buildings, consisting of thin steel sheets formed into studs and tracks. Structural steel framing, on the other hand, is used in large-scale industrial and commercial projects, utilizing heavy steel beams and columns for structural support. Lastly, cold-formed steel framing involves bending and shaping thin steel sheets into structural members, commonly used in non-load-bearing walls and partitions.

- Q: How are steel structures used in mining and mineral processing?

- Due to their durability, strength, and versatility, steel structures find extensive use in the mining and mineral processing industry. They serve multiple functions throughout the mining process, ranging from exploration and extraction to transportation and processing. In the exploration phase, steel structures are employed to create mine shafts and tunnels, ensuring stability and support for miners' safety and facilitating efficient mineral extraction from underground. Additionally, steel structures are utilized in constructing drilling rigs and equipment, enabling the exploration of new mineral deposits. During the extraction phase, steel structures are indispensable in the form of mining equipment, such as crushers, conveyors, and screens. These structures provide a robust framework for machinery, allowing for the efficient processing of ores and minerals. Steel is also used to construct storage facilities, including silos and bins, responsible for storing extracted minerals before further processing. Steel structures play a crucial role in transporting minerals within mining sites. Conveyor systems, often composed of steel, are employed to move bulk materials like coal, iron ore, and copper from one location to another. These structures are specifically designed to endure heavy loads and harsh conditions, ensuring the seamless flow of materials during mining and mineral processing operations. In the mineral processing phase, steel structures find extensive use. Processing plants, such as smelters and refineries, predominantly utilize steel due to its fire resistance and ability to withstand high temperatures. Steel tanks and vessels are employed to store and process chemicals, acids, and other substances involved in mineral processing. Moreover, steel structures contribute significantly to the construction of support buildings, offices, and maintenance facilities within mining sites. These structures provide a secure and functional environment for the mining workforce, facilitating efficient operations and ensuring employee well-being. In summary, steel structures are of utmost importance in mining and mineral processing, providing the necessary support, stability, and durability required for various operations. Their versatility allows for the construction of a wide range of structures, from mine shafts to processing plants, guaranteeing the smooth and efficient extraction and processing of minerals.

- Q: What are the design considerations for steel transmission towers?

- When designing steel transmission towers, several key considerations need to be taken into account to ensure their structural integrity, reliability, and efficient performance. These design considerations can be categorized into various aspects, including the tower's load capacity, material selection, structural design, and environmental factors. 1. Load Capacity: Steel transmission towers must be designed to withstand the loads they will experience throughout their lifespan. This includes dead loads (the weight of the tower structure and its components), live loads (such as wind, ice, and earthquake loads), and dynamic loads (such as those induced by conductor movement or line faults). The tower's design should account for these loads to prevent structural failure and ensure long-term stability. 2. Material Selection: Steel is commonly used for transmission towers due to its strength, durability, and cost-effectiveness. When selecting the type of steel, factors such as yield strength, ductility, and corrosion resistance should be considered. The choice of steel grade and protective coatings can enhance the tower's resistance to environmental conditions, such as corrosion in coastal or industrial areas. 3. Structural Design: The structural design of steel transmission towers involves determining the appropriate size, shape, and configuration of the tower components to meet the load requirements. The tower's height, base width, leg profile, and cross-sectional shape should be optimized to ensure stability, minimize material usage, and facilitate ease of construction. The design should also consider factors such as tower grounding, foundation design, and the connection between tower segments. 4. Environmental Factors: Steel transmission towers are exposed to various environmental conditions that can affect their performance. Wind is a critical factor, and towers must be designed to withstand wind speeds based on local regulations and site-specific conditions. Ice accumulation is another consideration in colder climates, as it can increase the load on the tower. Environmental factors such as temperature variations, seismic activity, and soil conditions should also be evaluated during the design process. 5. Maintenance and Inspection: Design considerations should also account for ease of maintenance and inspection. Access points, ladder systems, and platforms should be included to allow for safe and efficient tower inspections and repairs. Designing towers with suitable maintenance provisions can help extend their service life and minimize downtime. In conclusion, the design considerations for steel transmission towers encompass load capacity, material selection, structural design, environmental factors, and maintenance requirements. By carefully addressing these considerations, engineers can create robust and reliable transmission towers that meet the needs of the electrical grid while ensuring public safety and minimizing operational costs.

- Q: What are the factors to consider when designing steel structures for transportation infrastructure?

- When it comes to designing steel structures for transportation infrastructure, careful consideration must be given to several factors. These factors encompass: 1. Load capacity: It is crucial for the structure to withstand the expected loads and forces it will encounter over its lifespan. This includes the weight of vehicles, pedestrians, as well as additional loads like wind, seismic activity, or potential impacts. 2. Durability: Transportation infrastructure typically faces harsh environmental conditions, such as weathering, temperature fluctuations, and chemical exposure. To ensure long-term durability, the chosen steel must resist corrosion and other forms of deterioration. 3. Design life: The structure should align with the intended use and expected lifespan of the transportation infrastructure. This will determine the necessary maintenance and potential need for future modifications or expansions. 4. Safety: Safety is of utmost importance in transportation infrastructure. The design should consider factors like fire resistance, crashworthiness, and the ability to evacuate safely during emergencies. 5. Construction constraints: The construction process must be feasible and efficient. Site conditions, access for equipment and materials, and any potential restrictions or regulations impacting the construction process should be taken into account. 6. Aesthetics: Steel structures in transportation infrastructure play a significant role in the project's overall visual appearance. The design should consider architectural elements, such as shape, color, and texture, to ensure visual harmony with the surrounding environment. 7. Sustainability: The design should incorporate sustainable practices, considering the increasing focus on environmental responsibility. This may involve using recycled steel, energy-efficient designs, and the ability to dismantle or repurpose the structure easily at the end of its lifespan. 8. Cost-effectiveness: The overall cost of the steel structure, including construction, maintenance, and potential future modifications, should be considered. The design should aim to achieve the desired functionality and durability while minimizing unnecessary expenses. By accounting for these factors, designers can ensure that steel structures in transportation infrastructure are safe, durable, visually appealing, and cost-effective, ultimately contributing to the project's overall success and longevity.

- Q: What are the design considerations for steel food processing plants?

- Some design considerations for steel food processing plants include ensuring proper food safety and hygiene standards, creating efficient and flexible layouts to optimize workflow, incorporating appropriate ventilation and temperature control systems to maintain product quality, choosing durable and corrosion-resistant materials to withstand harsh cleaning chemicals, and implementing effective waste management systems to comply with environmental regulations. Additionally, considering the accessibility and maintenance of equipment and machinery, as well as the scalability and future expansion possibilities, are also important factors in the design process.

- Q: How do steel structures perform in terms of seismic resilience?

- Steel structures are highly resilient to seismic activity. The inherent strength and ductility of steel allow it to absorb and dissipate seismic forces, minimizing damage and ensuring structural stability during earthquakes. Additionally, steel's lightweight nature reduces the overall mass of the structure, which decreases the seismic load and enhances its performance. Consequently, steel structures have proven to be reliable and effective in withstanding seismic events, making them an excellent choice for earthquake-prone regions.

Send your message to us

steel structure workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords