Prefabricated steel structure warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Prefabricated steel structure warehouse materials:

| Material | Specification |

| Length | Single slope, double slope, muti slope |

| Width | Single span, double-span, Multi-span |

| Height | single floor, double floors |

| Column | Q235, Q345 welded H section steel |

| Beam | Q235, Q345 welded H section steel |

| Purlin | Q235 C channel or Z channel |

| Knee brace | Q235 angle steel |

| Vertical and transversal support | Q235 angle steel, round bar or steel pipe |

| Tie bar | Q235 steel pipe |

| Brace | Q235 round bar |

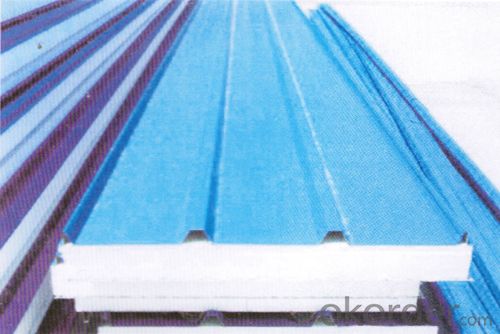

| Cladding system | EPS, PU, Fiber glass wool sandwich panels or corrugated steel sheet with fiber glass wool insulation. available in Diferent colors&gauge |

| Partition wall | sandwich panels (EPS, PU, Fiber glass wool etc.) available in Diferent colors&gauges |

| Door | sandwich panel sliding door or roller door |

| Gutter | stainless steel or color steel sheet |

| Rainspout: | PVC |

| Live load on roof | In 120kg/Sqm (Color steel panel surrounded) |

| Wind resistance grade | 12 grades |

| Earthquake-resistance | 8 - 9 grades |

| Structure usage | Up to 50 years |

| Finishing options | vast array of colors and textures available |

| Paint Options | Gray paint, red paint, white paint, expoxy zinc etc. Or Galvanized |

- Q: How do steel structures provide resistance against wind-borne debris impact?

- Steel structures provide resistance against wind-borne debris impact due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the force and impact of flying debris during high winds. Additionally, steel structures can be designed to have a streamlined shape or incorporate features such as deflectors or barriers, which help to divert or minimize the impact of debris. Overall, steel's robust nature and ability to absorb energy make it an ideal material for withstanding wind-borne debris impact.

- Q: How does steel perform in terms of thermal insulation?

- Steel is not typically known for its thermal insulation properties. In fact, steel is considered to be a good conductor of heat. This means that it is more likely to transfer heat rather than insulate against it. Steel's high thermal conductivity allows it to quickly absorb and distribute heat, making it unsuitable for applications where thermal insulation is a primary requirement. However, when used in combination with other insulating materials, such as insulation foam or mineral wool, steel can contribute to the overall insulation performance of a structure or product. Additionally, steel can be used as a thermal bridge, where it serves as a path for heat transfer, which can be undesirable in some cases. Overall, while steel itself may not excel in terms of thermal insulation, it can be effectively used in conjunction with other materials to achieve desired insulation levels in various applications.

- Q: What is the purpose of steel beams in structures?

- The purpose of steel beams in structures is to provide structural support and stability. Steel beams are used to carry and distribute the weight of the building or structure, ensuring that it remains strong and safe. They help to transfer loads from the roof, walls, and floors down to the foundation, allowing for larger open spaces and flexibility in architectural design. Additionally, steel beams have excellent strength-to-weight ratio, making them ideal for withstanding heavy loads and resisting deformation or collapse.

- Q: How are steel structures used in warehouses and storage facilities?

- Warehouses and storage facilities commonly utilize steel structures because of their strength, durability, and cost-effectiveness. These structures create a strong framework that can support heavy loads, allowing for efficient storage and organization of goods. In warehouses, steel structures are employed to construct large open spaces that can accommodate various storage systems, such as pallet racks, mezzanines, and shelving units. The high strength-to-weight ratio of steel enables the construction of tall, spacious buildings without the need for excessive support columns, maximizing storage space. Steel structures also offer flexibility in terms of layout and design. They can be easily modified or expanded to adapt to changing storage needs. The use of steel allows for wide-span structures, resulting in fewer interior columns and more open floor space. This facilitates efficient movement of goods and equipment within the facility, reducing material handling time. Furthermore, steel structures provide enhanced fire resistance compared to other building materials. This is particularly important in warehouses and storage facilities where the risk of fires is higher due to the presence of flammable materials. Steel is non-combustible and does not contribute to the spread of fire, ensuring the safety of stored goods and personnel. Additionally, steel structures are resistant to pests, such as termites and rodents, which can cause damage to the building and stored items. Steel does not rot or warp, ensuring the long-term integrity of the structure. This reduces maintenance and repair costs, making steel structures a cost-effective choice for warehouses and storage facilities. To summarize, steel structures are widely used in warehouses and storage facilities due to their strength, durability, flexibility, and cost-effectiveness. They provide a solid framework for efficient storage, maximize available space, offer fire resistance, and require minimal maintenance. These advantages make steel structures the optimal choice for businesses seeking to optimize their storage capabilities.

- Q: What does steel structure HW stand for?

- H is divided into hot-rolled H steel and welded H steel (H) two, hot-rolled H steel is divided into wide flange, H steel (HW), flange H (HM) and narrow flange H (HN) three.

- Q: What are the considerations for designing steel storage tanks?

- When designing steel storage tanks, there are several key considerations that need to be taken into account. Firstly, the structural integrity and stability of the tank must be ensured, as it will be holding a significant amount of weight. This involves selecting the appropriate steel material and thickness, as well as considering factors such as wind and seismic loads. Secondly, the tank design should consider the intended purpose and contents of the storage. Different materials may require specific design features to prevent corrosion, leakage, or contamination. Adequate ventilation and insulation may also be necessary, depending on the stored contents. Thirdly, the design should account for the tank's intended location and environmental conditions. Factors such as temperature variations, potential exposure to chemicals or harsh weather, and drainage requirements need to be considered to ensure the tank's durability and longevity. Additionally, safety considerations are crucial when designing steel storage tanks. This includes incorporating proper access points, such as ladders or platforms, and ensuring adequate safety features to prevent accidents or spills. Lastly, regulatory compliance is crucial. Designers must adhere to applicable codes, standards, and regulations related to the construction and operation of storage tanks. This ensures that the tank meets all necessary safety and environmental requirements. Overall, designing steel storage tanks requires careful consideration of structural integrity, material compatibility, environmental factors, safety, and regulatory compliance.

- Q: What is the role of steel trusses in a structure?

- Structural support and stability in a building or structure are crucially provided by steel trusses. These trusses are composed of interconnected steel members, typically in a triangular shape, that are designed to effectively distribute the load and resist the forces acting on the structure. The primary function of steel trusses is to bear and transfer the weight of the roof, floors, and other loads to the walls or columns of the structure. By evenly distributing the load, trusses prevent excessive stress concentration on any specific area, ensuring the overall structural integrity. Steel trusses are also highly durable and have a high strength-to-weight ratio, making them perfect for large-span structures like warehouses, factories, gymnasiums, and even bridges. Their strength enables them to withstand heavy loads and adverse weather conditions while maintaining their shape and stability over time. Furthermore, steel trusses offer design flexibility. They can be customized to fit various architectural styles and accommodate different roof shapes and configurations. This adaptability allows architects and engineers to create unique and aesthetically pleasing structures. Moreover, steel trusses are known for their easy installation and quick construction. Prefabricated trusses can be manufactured off-site, reducing construction time and labor costs. This makes steel trusses a cost-effective solution for many construction projects. In conclusion, steel trusses play a crucial role in providing robust support, efficient load distribution, structural stability, and design possibilities. Their strength, durability, and versatility make them an essential component in modern construction, contributing to the safety and longevity of buildings and structures.

- Q: How are steel structures used in the construction of retail centers and shopping complexes?

- Steel structures are commonly used in the construction of retail centers and shopping complexes due to their strength, durability, and versatility. Steel provides a high load-bearing capacity, allowing for large open spaces without the need for excessive columns or support walls. This enables architects and designers to create open, flexible layouts that can easily be adapted to accommodate changing tenant needs. Additionally, steel structures are resistant to fire, earthquakes, and other natural disasters, ensuring the safety of shoppers and employees. The use of steel also allows for faster construction times, reducing overall project costs and enabling retail centers and shopping complexes to open sooner.

- Q: What are the different types of steel stairs and railings used in structures?

- There are several different types of steel stairs and railings that are commonly used in various structures. These include: 1. Straight stairs: Straight stairs are the most basic and common type of staircase found in structures. They consist of a straight flight of stairs that connects two levels without any turns or curves. 2. L-shaped stairs: L-shaped stairs, also known as quarter-turn stairs, are designed to change direction at a landing. They are commonly used when space is limited or when there is a need to change the direction of the staircase. 3. U-shaped stairs: U-shaped stairs, also known as half-turn or switchback stairs, consist of two parallel flights of stairs that change direction at a landing, forming a U-shape. They are often used in larger structures where space is not a constraint. 4. Spiral stairs: Spiral stairs are a compact and visually appealing option that consists of a central column with steps spiraling around it. They are commonly used in structures with limited space or as a decorative feature. 5. Cantilevered stairs: Cantilevered stairs are a modern and minimalist design that gives the illusion of floating stairs. They are supported by a hidden structure, usually a wall or a beam, and do not require visible support underneath. 6. Glass railings: Glass railings are a popular choice for modern structures as they provide an unobstructed view and a sleek, contemporary look. They are often used in combination with steel frames or posts for added strength and stability. 7. Cable railings: Cable railings consist of horizontal or vertical cables that are tensioned between steel posts. They offer a sleek and minimalist appearance and are commonly used in contemporary structures or areas where visibility is important, such as balconies or outdoor decks. 8. Pipe railings: Pipe railings are made of steel pipes and are commonly used in industrial or commercial structures. They are durable, easy to install, and provide a sturdy and functional railing option. Overall, the choice of steel stairs and railings depends on the specific requirements of the structure, architectural design, and personal preferences. Different types of steel stairs and railings offer a range of options in terms of functionality, aesthetics, and space utilization.

- Q: What are the potential environmental impacts of steel structure manufacturing and construction?

- The steel structure manufacturing and construction industry can have several potential environmental impacts. One significant impact is the emission of greenhouse gases during the production of steel. Steel is primarily made from iron ore, which requires a substantial amount of energy and emits carbon dioxide (CO2) during the extraction and refining process. The CO2 emissions contribute to climate change and global warming. Another environmental concern is the extraction of raw materials. Steel production requires large quantities of natural resources, such as iron ore, coal, and limestone. The extraction of these materials can lead to habitat destruction, deforestation, and soil erosion. Mining activities may also cause water pollution, as chemicals used in the extraction process can contaminate nearby water sources. The manufacturing process also generates waste and pollutants. Steel mills produce various types of waste, including slag, dust, and emissions from furnaces. These by-products can harm air quality and contaminate nearby soil and water if not properly managed. Steel structures also have a significant impact during the construction phase. The transportation of steel components to the construction site requires energy and contributes to carbon emissions. Additionally, the construction process itself can lead to habitat destruction, noise pollution, and the generation of construction waste. However, there are steps that can be taken to mitigate these environmental impacts. The steel industry is continuously working on improving efficiency and reducing its carbon footprint. Techniques such as recycling steel scrap and using cleaner energy sources can help reduce the environmental impact of steel production. In construction, adopting sustainable practices such as using environmentally friendly materials, optimizing transportation routes, and minimizing waste generation can also mitigate the impact of steel structure construction on the environment. Additionally, designing structures that are energy-efficient and have a long lifespan can reduce the overall environmental footprint of steel structures. Overall, while the steel structure manufacturing and construction industry has potential environmental impacts, there are ways to mitigate these effects through sustainable practices and continuous improvement in manufacturing processes.

Send your message to us

Prefabricated steel structure warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords