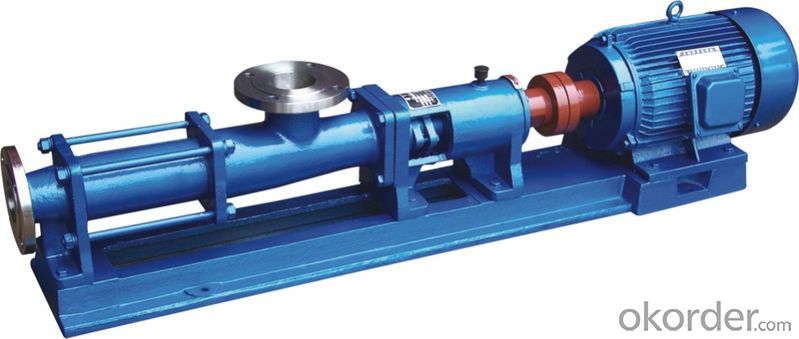

Positive Cavity Screw Pumps for Sewage Sludge and Polymer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Wide application, it can be used for conveying of flowing materials, even non-flowing materials

◆ Continuous conveying, small pulsating quantity

◆ The media is not stirred in the pump and is free from squeezing and cutting

◆ The flow is in direct proportion to the rotating speed, variable output, measurement feeding

◆Elastic stator, certain abrasion resistance

Conveying Medium of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Various viscous media (the highest viscosity reaches 106 mm2/s)

◆ Fluids with various concentrations and dewatered and dried materials

◆ The media containing solid particles, fibers and suspended solids

Multiple Configurations of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Materials: The parts can be made from different kinds of metals and rubber materials

◆ Drive: Motor speed reduction, motor speed regulation, mechanical speed regulation

FAQ

◆Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

◆Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

◆Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

◆Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: 2 different pulleys are in the way of the 2 remaining long bolts. at each end of the pump. tensioner did not need to be moved as belt is already off. Motor mount is 1/2 way removed and motor has dropped slightly gt; Am reading a jack must be placed under motor with wood via oil pan ( am hoping no other damage was done) Am told there is a certain device available to remove the pulleys? ... -Would appreciate anyone's info and advice on the remaining steps to this procedure on this make and model engine. as I have come into it obviously with it having begun the wrong way!! Thanks!!

- Are you sure? Try using a search engine (could be Bing, Yahoo, Google).

- Q: A pump parameter is the maximum flow per hour 960L, followed by the standard flow of 480 what do you mean?

- According to my estimate, a pump has the best working point, then this standard flow I think should refer to the best working point, that is to say you want to flow 480l/h, choose this pump is best

- Q: Water is pumped out of a holding tank at a rate of 6-6e^(-.09t) liters/minute, where t is in minutes since the pump is started. If the holding tank contains 1000 liters of water when the pump is started, how much water does it hold one hour later??Round your answer to one decimal place.

- Three okorder /

- Q: Hi, what is the difference between an Air pump and a Water pump. What are the functions of each? Does a tank filter come with an air pump? Is an Air pump or Water pump required?

- Air Pump For Water

- Q: I have a new water pump with its new gasket to be installed tomorrow. Do I still need to apply a gasket sealer (blue RTV silicone) on the gasket itself? If I do, do I need to apply it on both sides of the gasket? Thank you.

- that completely depends on the year/make and model, and type of gasket that it uses.

- Q: how often do i need to change a timing belt and water pump on my car? also, how much should it cost? should i have it done at the dealers or at a small mechanic shop if i chose to? which would be best? what are steps when having timing belt change?

- If it's Japanese, every 90,000 miles. If American, every 60,000 miles. Just recently changed belt and water pump on my Honda for $400 at an independent. Dealer is more expensive.

- Q: Mercedes 2000 ml 320. I changed radiator and water pump now car only runs half as worm than it used to. So now heat blows cold to little warm depending on how cold out side

- I don't mean to be a cheak but did you put all the pipes back where they should be and did you put the thermostat back in?

- Q: A water pump that consume 2kW of electric power when operating is claimedto take in water from a lake and pump it to a pool whose free surface is 30 m above the free surface of the lake at a rate of 50 L/s. Determine if this claim is reasonable.You have to show the minimum power required is 14.7 kWand i can't get it.

- A liter of water mas a mass of 1Kg. How much work must be done to raise 50 Kg of water through a height of 30 m? You can say: Work done (W) = potential energy gained (mgh), Or you can say that Work done is the weight force (mg) * the distance moved against the force (h) Either way, W = m * g * h where m is the mass; g is the acceleration due to gravity {9.8 m/s?}; h is the height W = 50 * 9.8 * 30 = 14700 J If you need to do that amount of work in one second, that's a rate of working of 14700 J/s A joule/second is a watt. Minimum power required = 14700 W = 14.7 kW

- Q: We have 2 1995 E320's that are heating up way too high when running. One has been diagnosed at the repair shop for a malfunctioning fan clutch. They also said that as the car was running hot the water pump and thermostat should also be replaced (??) The water pump is 5.5 hours of labor and I cannot afford it right now. I was wondering how hard to replace it myself. Thanks

- I have a 94 E320 in the shop right now with the same issue , running hot but not overheating and i wouldn't even consider replacing the water pump cause i have found the fan clutch not engaging at all . and you need a second opinion . is it possible for a water pump to cause this issue ....yes....is it likely.....NO if the fan clutch is engaging and the car still runs hot but does not overheat the thermostat is most likely not opening completely (sticking) and not allowing proper coolant flow . or you may have an inaccurate CTS .(coolant temp sensor) either way find a place who can properly diagnose your car . i hope this helps you

- Q: hooking up a water pump to my tank and need a power supply

- can you be a bit more descriptive have you a pump but no way of powering it if so what type of pump what voltage where is pump

Send your message to us

Positive Cavity Screw Pumps for Sewage Sludge and Polymer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords