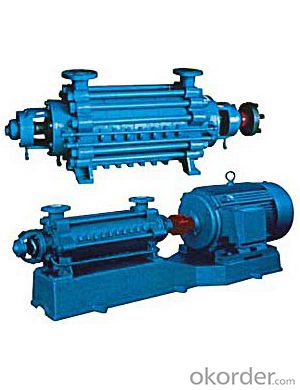

Multistage Boiler Feed Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Multistage Boiler Feed Centrifugal Water Pump

Operation parameters of Multistage Boiler Feed Centrifugal Water Pump

(1). Flow range: Q=6.3~450 m3/h

(2). Lift range: H=75~603m

(3). Diameter range: φ40~φ250mm

(4). Temperature range: 0 ~105°C

Product overview of Multistage Boiler Feed Centrifugal Water Pump

D pump is single-suction multi-stage sub-type centrifugal pump

(1). it is used to suction deliver water and the other liquid whose physical and chemical properties similar to water.

(2). If Change the material of impeller , seal ring, shaft sleeve and other parts, they also can be used to pump corrosive media,the liquid maximum temperature should not exceed 80°C.

MD wear-resistant multi-stage centrifugal pump is a wear-resistant multi-stage centrifugal pump

(1). It is designed on the basis of D single-suction multi-stage water centrifugal pump .

(2). MD pump is efficient , energy saving , wear-resistant and reliable,

(3). Drain the mine well water whose solid particle content is no more than 1.55 (particles diameter less than 0.5mm)and other similar liquid, the liquid temperature not exceed 80°C.

Product purpose of Multistage Boiler Feed Centrifugal Water Pump

(1). D, MD type multi-stage centrifugal pump is suitable for mine drainage, factory and city water supply.

(2). DG type boiler-feed pump is suitable for small boiler, cities and towns water supply, and other occasions.

Product features of Multistage Boiler Feed Centrifugal Water Pump

(1). with high efficiency, small size and other advantages,

(2). the components insist on high-precision processing technology,

(3). pump shaft of quenching and tempering treatment,

(4). the entire pump with excellent performance,

(5). and the products meet GB/T5657-95( centrifugal pump technical conditions standard

FAQ

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

- Q: Variable flow variable frequency water pump how to adjust the flow?

- Flow plus transmitter control

- Q: 95 mustang leaking water pump changed the pump and its running backward now

- Belt is routed incorrectly. Do not feel bad as this is actually a common mistake. Another possibility is the Parts Store sold you the wrong pump. This engine (5.0 I assume) was availiable in multiple vehicles and the Mustang was the only one I know of that had some that turned backwards

- Q: What is the 10KV pump unit?

- 10KV should refer to the motor start voltage value, ultra high voltage start, the general pump more than 160KW of the motor, the voltage used in 6KV, you motor should be more than 300KW

- Q: I have a Goulds JPlus water pump inside my home. Last night, my wife and I heard it going on and off repeatedly when we went to bed. I have two shallow wells hooked up to it, so I switched wells even though I didn't believe the one I was on was dry (it was supplying H2O fine).Still no luck, so I turned it off at the breaker and shut off the valve between the tank and pressure switch. Today, the pump pressure gets to between 50 and 60, then goes off. It then loses pressure v ery quickly (approx 10-20 seconds) and goes back on when the pump switch hits the lower threshold. It sounds like the water is running back through the pump and out of the house when it goes off unless I turn the shut off valve I spoke of earlier. I changed the pressure switch and no difference.I can, however, turn it on and shower, flush, etc. I just then have to go down and turn the pump back off.Any help would be greatly appreciated!

- If there is space try to hit the head of the bolt with a hammer, the shock from the hammer blow will help you to loosen the bolt. Failing that the next thing to try is an allen key socket, with this you can use a long strong arm to apply extra torque to the bolt. Be carefully not to open up the head of the bolt as this can be a major pain. If you still cannot get it out then if the water pump is to be replaced try to get an angle grinder on the bolt to cut its head off. Once the head is off and the pump is out you can use a stud extractor of a good vice grip to remove the stub of bolt left over.

- Q: how to change water pump on 1998 hyundai sonata?

- it really easy, first go to any car parts store near u, i recommand (napa) auto parts. u may ask for a book to look or ask for print out instruction. any way u need a wrench and some tools, look in the front, there r u radiator, follow the hose that came out and it will go to u engine and right there is u water pump, take the hose out and take water pump out and put the new one in, but some time it not the water pump, it could be the bell, or just the termostat locate on top of weter pump or to the side it the out water to go to engine , so how u know u water pump broke, but u want to save money get u phone book out and look for used auto parts and order u water pump around ($20) and just go to library and look for auto book and go from there, or go to auto zone ,they have print out for u, ...should na drive toyota

- Q: my water pump went bad on my 1997 chevy cavalier, causing it to leak all the coolant it had in the system. i put water in it til i could get new water pump. changed out water pump. attempted getting air out of system. put more concentrated coolant in system than i did water. bad guessing on my part. ran car around block 5 times. it was fine. this morning on the way to work, it started overheating again. my thoughts : more air in system that's not coming out? thermostat REALLY went bad at same time as water pump???? overheating all because of a little too much coolant??? for some crazy reason, my system needs to be suddenly flushed? Your thoughts? one last thing, the car has always ran perfectly normal temp til water pump went bad.

- Check your radiator,check your radiator fan to see if it works! Sometimes they go bad or their sensor won't work anymore and the car is overheating the sensor doesn't pick that up and the fan won't start! That's make the car overheating!

- Q: I have a leak coming from the water pump that flows down on the side of the AC compressor before landing on the ground. I cannot verify exactly where the leak is coming from on the pump, but I am sure it is the pump leaking because it also sounds bad like rattling. My question is do I have to remove any other components, such as the AC compressor to be able to remove the water pump. I would be great full for any suggestions.Regards,Steph

- Mercedes Benz Water Pump

- Q: How can the pump be stationary?

- 1, the pump can move under the premise of turning disc. Pump should be empty load start, that is, in the closing of the export valve in the state of start, there will be no rotation of the situation.2, look at the voltage of the circuit is normal, whether the lack of phase.

- Q: Replaced the water pump in my 89 f150 and now I have a pretty steady leak coming out. I don't know where the leak is coming from, but its running down the lower hose and dripping off it. I've replaced the lower hose and water pump, what could be causing this?

- Forgot the water pump gasket or sealant. Didn't torque the bolts. Didn't clean off the old gasket good enough. Left a piece of debris on the sealing surface. Didn't get the hose all the way on the water pump, didn't tighten the clamp enough. Check the simple things first. It's got to be one of those since the pump is new. Although not all new things work!! Sometimes you get a bad one especially if rebuilt.

- Q: I have a small leak in my water pump and my check engine light is on throwing a P0303 code and it appears the two might be related.

- Goofy cooling system sealers will not stop water-pump leaks. Think about it a minute! How can a cooling system sealer work on a moving water-pump in-put shaft, worn out bearing and leaking shaft seal? Apparently, you haven't read the complete list of the dozen or more causes of a P0303 code. The dealer of the car will be able to pinpoint the exact cause of the code.

Send your message to us

Multistage Boiler Feed Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords