Multistage Centrifugal Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

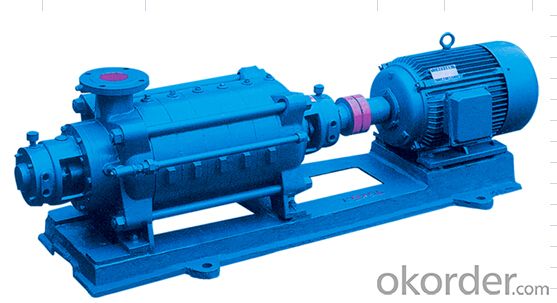

DG High Pressure Multistage Centrifugal Boiler Feed Water Pump

1.Structure of DG High Pressure Multistage Centrifugal Boiler Feed Water Pump Description

Boiler Feed Centrifugal Multistage Water Pumpis used for transporting pure water (particles density shall be max.1%by volumeand granular size shall be max 0.1mm in dimeter) of the liquids with physical and chemical properties similar to pure water. Type MD pump is applied with wear resist material, especially suitable for mineral drainage. The particles density shall be max. 1.5% (Max. of the granular diameter is 0.5 mm).The liquid temperature ofD, MD pumps shall be lower than 80°C.

2.Main Features of the DG High Pressure Multistage Centrifugal Boiler Feed Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. DG High Pressure Multistage Centrifugal Boiler Feed Water Pump images

4. DG High Pressure Multistage Centrifugal Boiler Feed Water Pump Specification

Item | Multistage Pump |

Multistage Pump | Horizontal Multistage Pump For Pure Water |

Model | CMD |

Material | Cast iron,Stainless steel |

Mode | Horizontal |

Color | Blue |

Temperature | <=80°c< span=""> |

Seal | packing seal |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Hot and cold pure water |

Outlet Diameter | 40-500mm |

Capacity | 6-1250 m3/h |

Head | 75-1800m |

Rotation Speed | 1450-2950r/min |

Power | 5.5-2400kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- For the first time, the pump and motor were placed on the base and not fastened (Cu Zhaozheng);Second times, the pump and motor have been tightened, the inlet and outlet flange bolts are not fastened;Third times, the pump runs 24 hours later.

- Q: What is a solution pump?

- Principle and structure features of canned motor pumpThe ordinary centrifugal pump is driven by coupling the pump impeller shaft is connected with the motor shaft, the impeller and the motor rotates while working and shielding pump is a kind of non seal pumps, pump and motor is sealed in a medium filled by pumping the pressure vessel, the pressure vessel only static seal and, by a group of wires to provide a rotating magnetic field and drive the rotor. This structure eliminated the traditional centrifugal pump with a rotary shaft sealing device, it can do no leakage.The pump and motor pump together, motor rotor and pump impeller fixed on the same shaft, use of shielding the rotor and the stator of the motor rotor separated in the medium, its power is transferred to the rotor through the stator magnetic field.

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- High speed rotating impeller blade drives the liquid to rotate, and the liquid is thrown out so as to achieve the purpose of conveying. There are many medium for transportation, such as oil, water, chemicals and so on. The pump shaft and the motor shaft are of the same shaft, the pump and the motor are made into an integral body and immersed in water. The medium of transportation is water.

- Q: Double floor sewage pump circuit diagram of a small problem

- Q 2, SA and SS are select switches, and different positions indicate the same difference between the two nodes. SA hits the left position 13, 14 to connect, hits to the right position 21, 22 to connect. SS hit the middle position, 5 and 6 turn on, 7 and 8 turn on; hit the right position; 1 and 2 turn on; 11 and 12 turn on; hit the left seat; 9 and 10 turn on; 3, 4 turn on.

- Q: Concrete pump 125 pipe wall thickness

- Concrete pump diameter 125mm, pipe wall thickness is generally 4mm, also have 4.25mm, 4.5mm, 4.75mm, need to be in accordance with the rules of transport.

- Q: What does centrifugal pump mean horizontally?

- Centrifugal pump horizontal opening meaning: pump shell and pump body along the pump blade horizontal central line is divided into the upper and lower halves, so that the maintenance of pump leaves when the pump top cover can be separated from the pump and bearing as a whole. No need to remove the pipe.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Maximum theoretical vertical transfer distance is m 270Maximum theoretical level conveying distance m 1200Distributing valve form S pipe valve (whole casting)

- Q: What is the main difference between SK water ring vacuum pump and 2BV water ring vacuum pump?

- The 2BV vacuum pump belongs to the machine pump coaxial type direct connection design. It saves space and is easy to install;The use of mechanical seals as standard configuration eliminates leakage and easy maintenance;Smooth running, low noise to 62 decibels;

- Q: Harm of air pump and pump

- Minimum starting current when centrifugal pump of such a small impact on the grid but long closed operation will make the liquid in the pump to the pump overheating temperature is too high will lead to the problem of the seal to a certain temperature will cause deterioration of oil bearing bearing caused by excessive wear and even bite dead

- Q: How accurate is the metering pump?

- In addition, when the oil supply is too large or the pipeline pressure rises unexpectedly, the volume of the liquid in the hydraulic chamber can be changed, thereby affecting the stability of the flow and reducing the metering accuracy of the pump. In order to solve the problem of how to stabilize the measurement accuracy of metering pump metering pump flow, how stable, the three valve device. The so-called actual refers to the combination of three functions including compensation, discharge and safety protection device or device supporting the hydraulic chamber, according to its action principle is different, is divided into automatic compensation and forced compensation two three valve device.

Send your message to us

Multistage Centrifugal Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords