Steel Frame Formwork withAllowable Pressure 60KN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

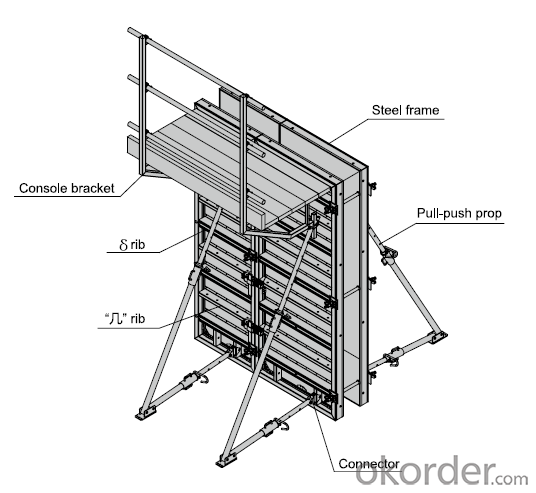

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

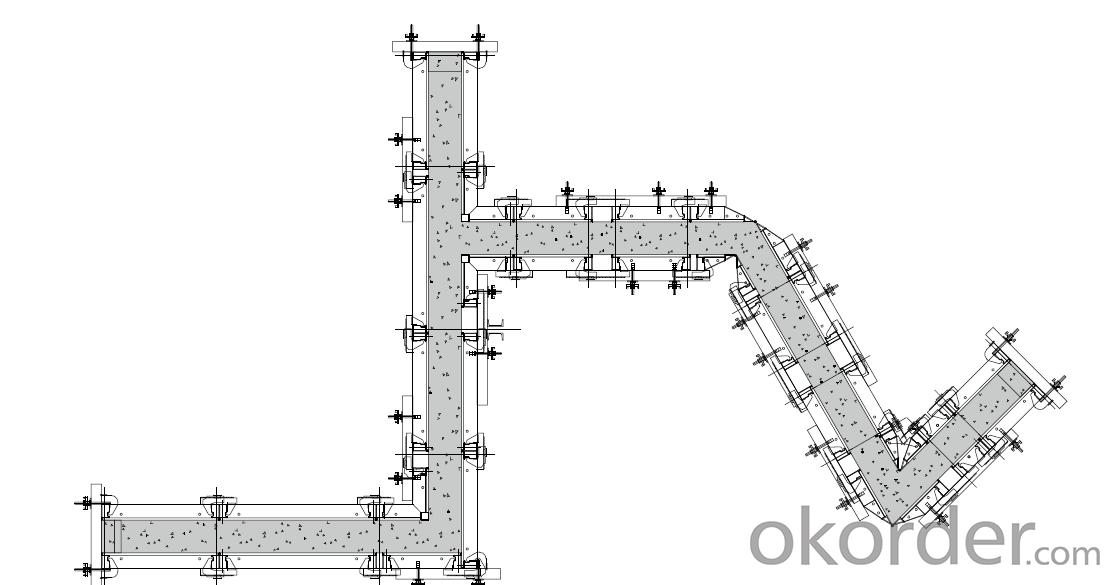

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How long does it take to assemble steel frame formwork?

- The assembly time for steel frame formwork can vary depending on several factors, including the size and complexity of the structure, the workers' experience and skill level, and the availability of equipment. On average, completing the assembly process can take anywhere from a few days to a couple of weeks. For smaller or simpler structures, setting up and securing the steel frames may only take a few days. During this stage, the frames are positioned according to the design specifications, securely connected, and checked for levelness and alignment. Any necessary adjustments or modifications may also be made at this time. However, for larger or more complex structures, the assembly process can take longer. This is due to a higher number of steel frames to install and align, additional bracing and support systems to incorporate, and more intricate connections to make. In such cases, it may take several weeks to complete the assembly process, especially if there are any unforeseen challenges or delays. It is important to note that the assembly time mentioned here specifically refers to the steel frame formwork itself and does not include tasks such as pouring and curing the concrete, which will add extra time to the overall construction timeline. To determine the precise assembly time for steel frame formwork in a particular project, it is advisable to consult experienced construction professionals who can assess the project requirements and provide a more accurate estimate.

- Q: Is the bamboo plywood and wood plywood the same?

- Bamboo plywood and wood plywood is not the same. Mainly different substrate

- Q: Can steel frame formwork be used in projects with limited construction resources or equipment?

- Yes, steel frame formwork can be used in projects with limited construction resources or equipment. Steel frame formwork is known for its durability and strength, making it suitable for various construction projects. Additionally, it can be easily reused multiple times, reducing the need for frequent replacements and saving costs. Its versatility allows it to be used in diverse construction scenarios, regardless of limited resources or equipment availability.

- Q: Can steel frame formwork be used for both residential and commercial projects?

- Steel frame formwork is versatile and can be utilized for both residential and commercial projects. This type of formwork offers numerous benefits, including its strength, durability, and flexibility, making it ideal for a wide range of construction endeavors. It can be employed to construct various types of concrete structures, such as walls, columns, slabs, and beams, which are commonly found in both residential and commercial buildings. Furthermore, steel frame formwork is reusable, providing a cost-effective solution for construction projects of various sizes. Consequently, whether it is a small residential dwelling or a large-scale commercial complex, steel frame formwork can be effectively utilized to ensure efficient and high-quality concrete construction.

- Q: Can steel frame formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel frame formwork can be used for both cast-in-place and precast concrete construction. Steel frame formwork provides a versatile and durable solution that can be easily adjusted and reused for different construction projects. It ensures precise and accurate shaping of concrete elements, whether they are cast on-site or produced in a precast facility.

- Q: What are the safety precautions for transporting steel frame formwork?

- Some safety precautions for transporting steel frame formwork include securing the frames properly to prevent shifting or falling during transport, using appropriate lifting equipment and techniques to avoid injuries, ensuring that the load is within the weight capacity of the vehicle, and following all relevant transportation regulations and guidelines. It is also essential to inspect the formwork for any damages or defects before transportation to prevent accidents or structural failure.

- Q: Can steel frame formwork be used in high-rise construction?

- Indeed, high-rise construction can make use of steel frame formwork. This option proves to be versatile and sturdy when it comes to erecting tall buildings. It possesses the necessary strength and stability to withstand the weight and pressure exerted by the concrete during the construction phase. Assembling and disassembling steel frame formwork is a straightforward task, which makes it suitable for repetitive use in high-rise projects. Furthermore, its adjustable features allow for accommodating various shapes and sizes of concrete structures. Employing steel frame formwork in high-rise construction guarantees efficiency and safety, resulting in accelerated project completion and improved structural integrity.

- Q: What are the different types of formwork connections used with steel frame formwork?

- Steel frame formwork can be used with several different types of connections to securely join the formwork panels together during the concrete pouring process. Some commonly used connections include the following: 1. Wedge connections: Steel wedges are inserted into pre-drilled holes in the formwork panels and tightened to hold the panels securely. 2. Bolted connections: Bolts, nuts, and washers are used to join the formwork panels. Holes are drilled in the panels and bolts are inserted through them, with nuts and washers tightened to secure the panels. 3. Pin and wedges connections: Steel pins are inserted into holes in the formwork panels, and wedges are driven into slots on the pins to hold the panels together. 4. Clamping connections: Clamps or clamping devices are used to join the formwork panels. These clamps are tightened around the panels, applying pressure for a secure connection. 5. Magnetic connections: Magnets embedded within the formwork panels create a strong bond between them, eliminating the need for additional connectors. 6. Hook and loop connections: Straps with hook and loop fasteners are used to join the formwork panels. These straps are wrapped around the panels, providing a secure connection. The choice of formwork connection depends on factors such as project requirements, the formwork system being used, and the desired level of ease and speed of assembly. Each type of connection has its own advantages and disadvantages.

- Q: Can steel frame formwork be used in projects with strict environmental regulations?

- Yes, steel frame formwork can be used in projects with strict environmental regulations. Steel is a highly sustainable and recyclable material, and using steel frame formwork can help minimize the environmental impact of construction projects. Additionally, steel frame formwork offers durability and reusability, reducing waste generation and promoting a more sustainable construction process.

- Q: How does steel frame formwork facilitate the construction of walls and columns?

- Steel frame formwork facilitates the construction of walls and columns by providing a sturdy and reusable structure for pouring concrete. The steel frames can be easily assembled and disassembled, allowing for efficient and rapid construction. Additionally, the formwork provides accurate dimensions and smooth finishes, ensuring high-quality and precise construction of walls and columns.

Send your message to us

Steel Frame Formwork withAllowable Pressure 60KN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords