Light Steel Frame Formwork for Lower Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. CMAX Light Steel Frame Formwork Description

CMAX Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of Light Steel Frame Formwork

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

- We can special design according to any requirements.

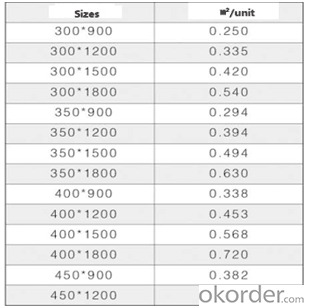

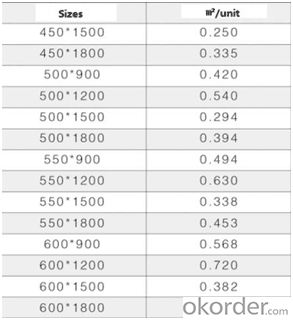

3. Light Steel Frame Formwork Specifications

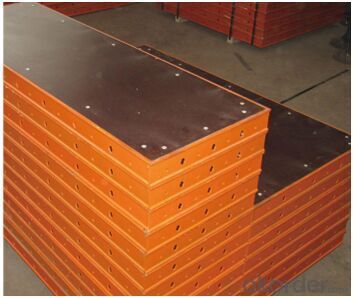

4. Light Steel Frame Formwork Images

5. FAQ of Light Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: What are the different types of formwork anchors used with steel frame formwork systems?

- There are several types of formwork anchors used with steel frame formwork systems. These anchors are essential for providing stability and support to the formwork during the concrete pouring process. Some of the different types of formwork anchors include: 1. Loop Ties: Loop ties are commonly used for attaching formwork panels to the steel frame. They consist of a looped wire that is inserted through the formwork and secured to the frame using tie rods or other fastening methods. 2. Adjustable Clamps: Adjustable clamps are used to secure the formwork panels to the steel frame. These clamps can be easily adjusted to accommodate different panel thicknesses and provide a tight connection. 3. Wedges: Wedges are used to secure the formwork panels to the steel frame. They are inserted into specially designed slots on the frame and provide a strong and secure connection. 4. C-clamps: C-clamps are used to attach formwork panels to the steel frame. They have a C-shaped design that allows them to easily slide onto the frame and provide a secure connection. 5. Formwork Brackets: Formwork brackets are used to support the formwork panels and provide additional stability. These brackets are attached to the steel frame and can be adjusted to the desired height and angle. 6. Formwork Ties: Formwork ties are used to connect multiple formwork panels together. They are inserted through the panels and secured to the steel frame using tie rods or other fastening methods. 7. Combination Anchors: Combination anchors are versatile anchors that can be used for various applications. These anchors combine different elements such as loops, clamps, and wedges to provide a secure connection between the formwork panels and the steel frame. These are just a few examples of the different types of formwork anchors used with steel frame formwork systems. The choice of anchor will depend on factors such as the formwork design, load requirements, and specific project needs. It is important to select the appropriate anchor to ensure the stability and safety of the formwork during the concrete pouring process.

- Q: How does steel frame formwork handle concrete pouring at different heights?

- Steel frame formwork is a versatile and reliable system that can easily handle concrete pouring at different heights. The key to its effectiveness lies in its adjustable nature and strong structural design. Firstly, steel frame formwork is designed to be adjustable, allowing it to be easily adapted to different heights. The frames can be extended or shortened to the desired level, ensuring that the formwork fits securely and firmly against the concrete structure. This adjustability feature is particularly useful when pouring concrete at different heights, as it allows for seamless transitions and ensures a consistent and uniform finish. Additionally, the steel frame formwork system is built with durability and strength in mind. Steel is a robust material that can withstand the weight and pressure of the concrete during pouring. It provides excellent support and stability, ensuring that the formwork remains in place and does not deform or collapse under the weight of the concrete. This is crucial when pouring concrete at different heights as it guarantees the safety and integrity of the structure. Moreover, steel frame formwork is versatile and can be easily customized to accommodate various architectural designs and requirements. It can be used for both horizontal and vertical concrete placements, making it suitable for different types of construction projects. Whether pouring concrete at ground level or at elevated heights, the steel frame formwork system can be adapted to meet the specific needs of each situation. In conclusion, steel frame formwork is a reliable and adaptable system that handles concrete pouring at different heights with ease. Its adjustable nature and strong structural design ensure that it provides secure support and stability during the pouring process. This versatility and durability make steel frame formwork an ideal choice for construction projects requiring concrete placement at varying heights.

- Q: Are there any limitations on the height of structures that can be constructed using steel frame formwork?

- Yes, there are limitations on the height of structures that can be constructed using steel frame formwork. The height limitation primarily depends on the design and engineering considerations, as well as the capabilities of the steel frame formwork system being used. One of the main factors that can limit the height is the load-bearing capacity of the steel frame formwork. The formwork needs to be able to support the weight of the concrete and any additional loads, such as construction equipment or workers. If the height of the structure exceeds the load-bearing capacity of the formwork, it can lead to structural instability and potential collapse. Additionally, the stability and rigidity of the steel frame formwork system play a crucial role in determining the maximum height. As the height increases, the formwork system needs to be able to withstand the lateral forces, wind loads, and other external factors that can affect the stability of the structure. If the formwork system is not designed to handle these forces, it can compromise the safety and integrity of the construction. Moreover, the availability of suitable equipment and technology can also impose limitations on the height of structures constructed using steel frame formwork. Taller structures may require specialized equipment, such as high-capacity cranes or lifting systems, to assemble and dismantle the formwork. If such equipment is not available or feasible, it can restrict the height that can be achieved using steel frame formwork. Lastly, local building codes and regulations also often dictate the maximum height of structures. These regulations are put in place to ensure the safety and stability of buildings and to prevent any potential risks to the surrounding environment. It is important to adhere to these regulations and obtain appropriate permits when constructing tall structures using steel frame formwork. In conclusion, while steel frame formwork offers versatility and strength in construction, there are limitations on the height of structures that can be built using this system. The load-bearing capacity, stability, availability of equipment, and local regulations are some of the factors that determine the maximum height achievable. It is essential to consult with experienced engineers and adhere to safety guidelines to ensure the successful construction of tall structures using steel frame formwork.

- Q: How long does it take to assemble steel frame formwork?

- The assembly time for steel frame formwork can vary depending on several factors, including the size and complexity of the structure, the workers' experience and skill level, and the availability of equipment. On average, completing the assembly process can take anywhere from a few days to a couple of weeks. For smaller or simpler structures, setting up and securing the steel frames may only take a few days. During this stage, the frames are positioned according to the design specifications, securely connected, and checked for levelness and alignment. Any necessary adjustments or modifications may also be made at this time. However, for larger or more complex structures, the assembly process can take longer. This is due to a higher number of steel frames to install and align, additional bracing and support systems to incorporate, and more intricate connections to make. In such cases, it may take several weeks to complete the assembly process, especially if there are any unforeseen challenges or delays. It is important to note that the assembly time mentioned here specifically refers to the steel frame formwork itself and does not include tasks such as pouring and curing the concrete, which will add extra time to the overall construction timeline. To determine the precise assembly time for steel frame formwork in a particular project, it is advisable to consult experienced construction professionals who can assess the project requirements and provide a more accurate estimate.

- Q: How does steel frame formwork contribute to the overall aesthetics of a concrete structure?

- The overall aesthetics of a concrete structure are enhanced by steel frame formwork in various ways. To begin with, the placement of concrete becomes more precise and accurate with steel frame formwork, resulting in a smoother and more uniform finish. This is particularly crucial when the exposed concrete surface is intended to be a prominent design feature. Additionally, steel frame formwork offers flexibility in shaping and molding the concrete. The steel frames can be easily adjusted and customized to create different shapes, curves, and patterns, opening up more creative design possibilities. This allows architects and designers to create concrete structures that are unique and visually appealing, setting them apart from conventional construction methods. Furthermore, steel frame formwork contributes to achieving a consistent and level surface finish across the entire structure. The strong and sturdy nature of steel frames ensures that the formwork remains stable and does not deform during the concrete pouring process. As a result, there is no risk of uneven surfaces or imperfections, resulting in a visually pleasing and professional appearance. Moreover, steel frame formwork also enhances the durability and longevity of the concrete structure. The use of steel frames provides robust support and reinforcement to the concrete, making it more resistant to external forces and potential damage. This guarantees that the structure maintains its aesthetic appeal over time, as the concrete surface remains intact and free from cracks or deterioration. In conclusion, steel frame formwork plays a crucial role in enhancing the overall aesthetics of a concrete structure. It enables precise and accurate concrete placement, offers design flexibility, ensures a consistent and level finish, and contributes to the durability and longevity of the structure. By combining functionality and aesthetics, steel frame formwork helps create visually stunning and architecturally impressive concrete structures.

- Q: How does steel frame formwork compare to traditional timber formwork?

- Steel frame formwork is generally considered to be superior to traditional timber formwork in several aspects. Firstly, steel frame formwork offers higher strength and durability, ensuring a longer lifespan and reducing the need for frequent replacements. Additionally, steel frame formwork provides greater stability and resistance to deformation, resulting in more accurate and consistent concrete structures. Moreover, steel frame formwork is typically easier to assemble and disassemble, saving both time and labor costs. Lastly, steel frame formwork offers better reusability, making it a more sustainable and cost-effective option in the long run. Overall, steel frame formwork outperforms traditional timber formwork in terms of strength, durability, stability, ease of use, and sustainability.

- Q: How does steel frame formwork handle the placement of stairs and escalators within the concrete structure?

- A versatile and flexible system, steel frame formwork effectively handles the placement of stairs and escalators in concrete structures. When constructing stairs, steel frame formwork provides reliable support. The steel frames easily adjust to desired dimensions and designs, allowing for various types of staircases such as straight flights, spiral stairs, or curved designs. This flexibility promotes creativity in architectural designs and ensures seamless integration into the overall structure. For escalators, steel frame formwork offers necessary strength and stability. It can be designed to match escalator dimensions and configurations, providing a secure framework for installation. The engineered steel frames withstand dynamic forces and vibrations associated with escalator operations, ensuring long-term durability and safety. Additionally, steel frame formwork allows for efficient and speedy construction of stairs and escalators in concrete structures. Prefabricated steel frames are easily assembled and adjusted on-site, reducing construction time and labor costs. The modular system enables quick dismantling and reassembly, ideal for projects requiring frequent changes or modifications in stair and escalator positioning. Overall, steel frame formwork is the preferred choice for architects, contractors, and engineers in constructing buildings with stairs and escalators. Its flexibility, strength, and efficiency make it an ideal solution for incorporating these vertical transportation systems.

- Q: How does steel frame formwork handle different types of concrete mixes and aggregates?

- Steel frame formwork is a versatile and robust system that can handle different types of concrete mixes and aggregates effectively. Its strong and rigid structure ensures the containment of various types of concrete mixes, including lightweight, normal weight, and heavyweight concrete. Additionally, the adjustable height and width of the steel frames allow for accommodating different aggregate sizes, whether it is fine or coarse aggregates. The stability and durability of steel frame formwork make it suitable for handling the varying characteristics of concrete mixes and aggregates, ensuring a reliable and consistent construction process.

- Q: What are the different types of corner systems available for steel frame formwork?

- There are several different types of corner systems available for steel frame formwork, each with their own unique features and benefits. 1. Adjustable Corner System: This type of corner system allows for easy adjustment and flexibility in forming corners of various angles. It typically consists of adjustable steel brackets or connectors that can be modified to accommodate different corner angles. This system is ideal for projects that require frequent changes in corner angles or for irregularly shaped structures. 2. Standard Corner System: The standard corner system is a traditional method of forming corners using steel angles or channels. It is a simple and cost-effective solution for forming right-angle corners. This system is commonly used in projects where the corner angles are fixed and do not require any adjustment. 3. Pre-fabricated Corner System: This type of corner system consists of pre-fabricated steel corner units that are designed to fit perfectly into the formwork system. These units are manufactured off-site and can be easily assembled and installed on-site. They provide a quick and efficient solution for forming corners, saving time and labor costs. 4. Magnetic Corner System: The magnetic corner system utilizes magnets embedded in steel plates to create a strong and secure connection between the formwork panels at corners. This system eliminates the need for additional corner connectors or brackets, resulting in faster installation and easier dismantling. It is particularly beneficial for repetitive use in projects where corners need to be formed quickly and efficiently. 5. Hinged Corner System: The hinged corner system allows for easy adjustment and manipulation of corner angles. It consists of hinged steel plates or brackets that can be folded or unfolded to form corners at different angles. This system is commonly used in projects where the corner angles need to be adjusted frequently, such as in architectural structures or curved walls. Overall, the choice of corner system depends on the specific requirements of the project, including the desired corner angles, ease of installation, adjustability, and cost-effectiveness. Consulting with a professional formwork engineer or supplier can help determine the most suitable corner system for a particular steel frame formwork project.

- Q: How does steel frame formwork compare to plastic formwork?

- Steel frame formwork is generally considered to be more durable and long-lasting compared to plastic formwork. It offers higher strength and stability, making it ideal for heavy-duty applications and large-scale construction projects. Steel formwork is also reusable, which reduces the overall cost and waste generated. On the other hand, plastic formwork is lightweight and easier to handle, making it suitable for smaller projects and quick installations. However, it may not withstand heavy loads or harsh weather conditions as well as steel formwork. Ultimately, the choice between steel frame formwork and plastic formwork depends on the specific requirements and scale of the construction project.

Send your message to us

Light Steel Frame Formwork for Lower Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches