Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Duty Whole Steel Formwork

55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Light Duty Whole Steel Formwork

-Clean and tidy steel panel

-Light weight

-Reduced and Competitive cost

-Solid Steel panel

-Easy to dismantle

-Repeated use of 20 times

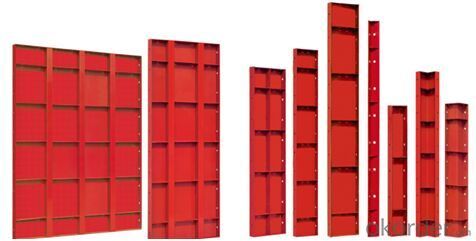

3. Light Duty Whole Steel Formwork images

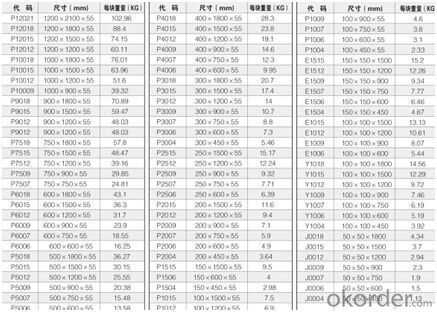

4. Light Duty Whole Steel Formwork Specifications

5. FAQ of Light Whole Steel Formwork

1) What can we do for you?

.We can ensure the quality of the Heavy Duty Whole Steel Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel formwork be used for both straight and curved concrete elements?

- Yes, steel formwork can be used for both straight and curved concrete elements. Steel formwork is highly versatile and can be easily adjusted and shaped to accommodate different design requirements. It offers excellent strength and durability, making it suitable for constructing both straight and curved concrete elements. The flexibility of steel formwork allows for the creation of complex and intricate shapes, making it ideal for projects that require curved elements such as architectural features, curved walls, or circular structures. Additionally, steel formwork provides a smooth and uniform surface finish, ensuring high-quality concrete results for both straight and curved elements.

- Q: How does steel formwork handle different concrete crack control measures?

- Steel formwork offers versatility and durability when it comes to dealing with various concrete crack control measures. One of its main benefits lies in its ability to provide a sturdy structure that effectively withstands the forces exerted during concrete pouring and curing. This rigidity plays a vital role in reducing the occurrence of cracks in the concrete. When considering crack control measures, steel formwork brings several advantages. Firstly, its smooth surface allows for easy placement and compaction of the concrete, minimizing the chances of voids and air pockets that can lead to cracking. Furthermore, steel formwork can be specifically designed to accommodate different reinforcing measures, such as rebar and mesh, further enhancing crack control. Additionally, steel formwork allows for precise control over the curing process. Contractors can regulate the rate of concrete hydration by utilizing steel forms, which is crucial in crack control. Proper curing techniques, including the application of curing compounds or the implementation of thermal insulation, can be easily executed with steel formwork, guaranteeing optimal conditions for crack prevention. In terms of crack repair, steel formwork offers an advantage by providing easy access to the concrete surface. In the event of cracks, repairs can be conducted by directly injecting epoxy or other suitable materials into the affected areas. The rigidity of steel formwork ensures that the repaired sections maintain their structural integrity and prevent further cracking. Overall, steel formwork proves to be a dependable solution for managing various concrete crack control measures. Its rigidity, smooth surface, and compatibility with reinforcing measures make it highly efficient in minimizing cracks during the pouring, curing, and repair stages of concrete construction.

- Q: Are there different sizes of steel formwork available?

- Indeed, a variety of sizes of steel formwork can be found. Steel formwork, a versatile construction material, sees extensive use in a multitude of building endeavors. Its inherent strength, durability, and stability render it well-suited for diverse applications. Customization of steel formwork to match specific project demands facilitates the creation of various shapes and structures, enabling flexibility. Moreover, the utilization of steel formwork facilitates efficient construction procedures, owing to its effortless assembly and disassembly, rendering it suitable for projects of all scales, be they small or large.

- Q: How does steel formwork prevent concrete shrinkage and cracking?

- Steel formwork helps prevent concrete shrinkage and cracking by providing strong and rigid support during the curing process. When concrete is poured into the steel formwork, it takes the shape of the structure being built and hardens over time. The steel formwork acts as a mold, holding the concrete in place and preventing it from shrinking or cracking as it dries. One of the main causes of concrete shrinkage and cracking is the loss of moisture during the curing process. As the water in the concrete evaporates, it causes the material to shrink. This shrinkage can lead to cracks forming in the concrete if it is not properly supported. Steel formwork helps prevent this shrinkage by providing a tight and secure enclosure for the concrete. It ensures that the concrete retains its moisture and does not dry out too quickly. This slow and controlled drying process allows the concrete to cure evenly and reduces the likelihood of shrinkage and cracking. Additionally, steel formwork provides stability and support to the concrete, preventing it from moving or shifting as it hardens. This stability helps to distribute the forces and stresses evenly, reducing the risk of cracking or structural failure. Furthermore, the smooth and rigid surface of steel formwork helps to achieve a high-quality finish on the concrete. This prevents any irregularities or imperfections that may weaken the structure or make it more susceptible to cracking. In summary, steel formwork plays a crucial role in preventing concrete shrinkage and cracking by providing support, stability, and moisture retention during the curing process. Its strong and rigid structure ensures that the concrete remains intact and achieves a high-quality finish, reducing the risk of structural issues and enhancing the durability of the construction.

- Q: How long does steel formwork last?

- Various factors, including the quality of the steel used, the frequency and type of usage, and the maintenance practices employed, can affect the lifespan of steel formwork. Typically, steel formwork is renowned for its durability and longevity, and with proper maintenance, it can endure for numerous years or even decades. When steel formwork is consistently maintained and handled correctly, it can endure multiple uses and continue to function effectively. However, it is important to acknowledge that over time, steel formwork may experience wear and tear due to constant exposure to concrete, which can result in surface corrosion or deterioration. To address this, protective coatings can be applied or the formwork can be cleaned after each use. Moreover, external factors like environmental conditions and the type of concrete used can also impact the lifespan of steel formwork. Exposure to harsh weather conditions or chemicals can expedite the corrosion process, potentially reducing the formwork's lifespan. To ensure the durability of steel formwork, it is crucial to invest in high-quality steel with proper anti-corrosion properties, conduct regular inspections, and perform necessary maintenance and repairs as required. By adhering to these practices, steel formwork can endure for a significant period, making it a cost-effective and dependable choice for construction projects.

- Q: How does steel formwork handle different concrete slump flow measurements?

- Steel formwork offers versatility and durability when dealing with various measurements of concrete slump flow. Slump flow is a gauge of concrete's consistency and workability, indicating its capacity to flow and fill the formwork. Designed to be rigid and robust, steel formwork can withstand the weight and pressure of poured and cured concrete. This ensures that it effectively contains and supports concrete with different slump flow measurements, preventing any deformation or failure. One advantage of steel formwork lies in its ability to easily adapt to changes in concrete slump flow. It can be adjusted or modified to accommodate varying levels of fluidity and workability. By tightening or loosening the formwork panels, the desired shape and size can be achieved, ensuring proper containment and shaping of the concrete, regardless of its slump flow measurement. Furthermore, steel formwork provides a smooth and uniform surface for the concrete, which is crucial for achieving a high-quality finish. The steel's rigid structure guarantees that the formwork remains in place during the pouring process, minimizing the risk of any movement or displacement that could negatively affect the concrete's performance and appearance. Additionally, steel formwork is resistant to moisture and chemicals, which are often present in concrete mixtures. This resistance ensures that the formwork remains in excellent condition even when exposed to different slump flow measurements, preventing any degradation or corrosion that could compromise its strength and stability. Overall, steel formwork proves to be a dependable and efficient choice for handling different measurements of concrete slump flow. Its strength, adaptability, and resistance to moisture and chemicals make it well-suited for containing and shaping concrete with varying levels of workability, ensuring successful construction projects.

- Q: How does steel formwork affect the cost of construction?

- The overall cost of construction can be significantly influenced by steel formwork. Despite the need for a greater initial investment compared to traditional formwork materials like wood or plywood, steel formwork offers several advantages that can help counterbalance the increased cost. To begin with, steel formwork is highly durable and long-lasting, enabling it to be reused multiple times. Unlike wood or plywood formwork, steel formwork does not warp, rot, or deteriorate over time. This ability to be reused reduces the necessity for frequent formwork replacements, resulting in material cost savings in the long term. Moreover, steel formwork provides exceptional strength and stability, allowing for the construction of intricate and high-quality concrete structures. This strength permits the usage of thinner formwork elements, reducing the overall weight of the formwork system. Consequently, less labor and equipment are required for handling and installation, resulting in cost savings in terms of manpower and machinery. Furthermore, steel formwork facilitates faster construction cycles. The smooth and precise surface finish provided by steel formwork diminishes the need for extensive finishing work. This streamlined construction process saves time, ultimately reducing labor costs and project timelines. Additionally, steel formwork enhances safety on construction sites. Its robust nature and secure connections guarantee stability during concrete pouring and curing, minimizing the risk of accidents or structural failures. This improved safety aspect can help decrease insurance costs and potential legal liabilities. Lastly, steel formwork is highly adaptable and customizable. It can be easily modified and adjusted to accommodate various design requirements, making it suitable for a wide range of construction projects. This flexibility optimizes material usage and ensures minimal wastage, thereby reducing overall construction costs. In conclusion, although steel formwork may initially incur a higher cost, its long-term benefits such as reusability, strength, speed, safety, and adaptability contribute to overall cost savings in construction projects. Its durability and efficiency make it a cost-effective choice that can positively impact the quality, timeline, and budget of any construction undertaking.

- Q: How much time does it take to install steel formwork?

- The amount of time it takes to install steel formwork can vary depending on several factors such as the size and complexity of the project, the level of experience and skill of the workers, and the availability of necessary equipment and resources. However, on average, the installation of steel formwork can take anywhere from a few hours to a few days. Smaller and simpler projects may be completed relatively quickly, while larger and more intricate projects may require more time and effort. It is important to carefully plan and coordinate the installation process, considering factors such as the number of formwork panels, their size and weight, and the necessary support systems. Additionally, factors such as weather conditions and site-specific challenges may also impact the time required for installation.

- Q: What is the 86 series steel formwork

- Steel template (also called undismantled Mould Network) can replace the wood template, significantly reduced usually with wood, plywood, steel plate or other traditional sealing template on the pore water pressure and the pressure in the bubble concrete elimination; steel template (undismantled Mould Network) structure of concrete casting, forming an ideal rough interface. Do not need to rough cutting operations can enter the next construction processThe utility model can be placed before installing the reinforcing steel bar, and can also be placed after installing the reinforcing steel bar. If it is installed before the installation of steel, easy installation and easy to install; concrete pouring process can be visually monitored, thereby reducing the risk of the emergence of pores and honeycomb structure and other phenomena.

- Q: What are the typical safety certifications for steel formwork systems?

- There are several safety certifications that are typically required for steel formwork systems to ensure their quality and compliance with safety standards. These certifications include: 1. ISO 9001: This certification ensures that the manufacturer of the steel formwork system has implemented a quality management system, which includes procedures for design, production, and installation processes. It guarantees that the system meets the required standards and specifications. 2. European Conformity (CE) Marking: This certification is mandatory for steel formwork systems sold in the European Union. It confirms that the product complies with the essential health and safety requirements of the EU directives. The CE marking ensures that the steel formwork system has undergone rigorous testing and meets the necessary safety standards. 3. Occupational Safety and Health Administration (OSHA) Compliance: In the United States, steel formwork systems must comply with the safety regulations set by OSHA. These regulations include requirements for fall protection, scaffolding safety, and other related safety measures. Compliance with OSHA standards ensures the safety of workers involved in the installation and use of the steel formwork system. 4. American National Standards Institute (ANSI) Certification: ANSI provides standards and certifications for various products, including steel formwork systems. ANSI certification ensures that the system meets specific safety and performance requirements, providing reassurance to users that it has been rigorously tested and meets industry standards. 5. International Code Council Evaluation Service (ICC-ES) Certification: This certification provides independent verification that the steel formwork system complies with the International Building Code (IBC) requirements. It ensures that the system has been evaluated and deemed safe for use in construction projects. These safety certifications are essential for steel formwork systems to demonstrate their compliance with industry standards, ensuring the safety of workers and the reliability of the system during construction projects. It is crucial for manufacturers and suppliers to obtain these certifications to instill confidence in their products and facilitate their use in various construction projects worldwide.

Send your message to us

Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords