Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Whole Steel Formwork Description

CMAX Whole Steel Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort. 55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Construction Steel Formwork

- Simple structure, high loading capacity.

- Light weight, easy assemble.

- Excellent surface quality of formed concrete.

- We can special design according to any requirements.

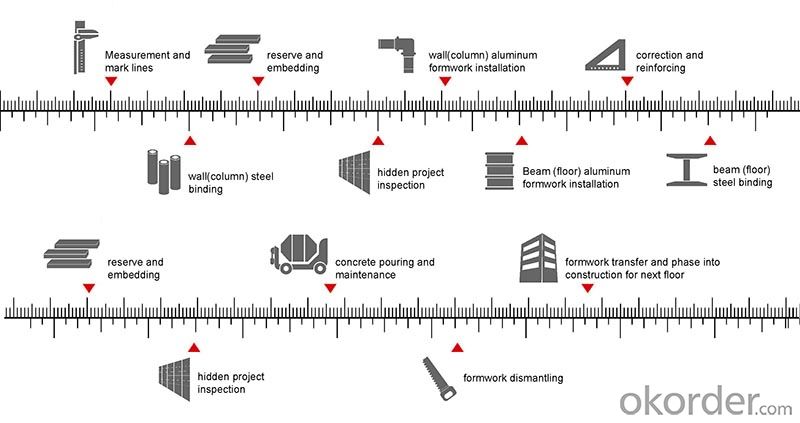

3. Construction Process

4. FAQ of Steel Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: What are the common design considerations for steel formwork?

- To ensure the efficiency and effectiveness of steel formwork design, several factors must be taken into account. Firstly, the load-bearing capacity of the formwork needs careful calculation and design to support the weight of fresh concrete and any additional loads without deformation or failure. This involves evaluating maximum expected load and selecting the appropriate steel grade and thickness. Secondly, the formwork should be easily assembled and disassembled, which is crucial for projects with tight schedules or limited space. Modular components that can be quickly and accurately connected should be used, allowing for efficient construction and easy removal after the concrete cures. Thirdly, the desired surface finish of the concrete should be considered in the formwork design. Proper alignment and leveling are necessary for a smooth and consistent finish. Additionally, the formwork should be designed to prevent leakage or seepage, which could cause imperfections or structural issues. Stability and rigidity are also important considerations. The formwork must withstand lateral pressure from the fresh concrete without significant deformation or displacement. Proper bracing and tie systems should be incorporated for stability during the pouring process. Safety should be prioritized in the formwork design, providing a safe working environment with adequate access, guardrails, and fall protection systems. Installation and removal of safety features should also be considered. Lastly, the reusability and durability of the steel components should be taken into account. The formwork should be designed to withstand repeated use and resist corrosion or wear. Maintenance and storage considerations are also important for prolonging the lifespan of the formwork. In conclusion, the design of steel formwork should consider load-bearing capacity, ease of assembly and disassembly, surface finish requirements, stability and rigidity, safety, reusability, and durability. By carefully considering these factors, well-designed steel formwork can contribute to the successful and efficient construction of concrete structures.

- Q: Can steel formwork be used for both vertical and horizontal applications?

- Indeed, both vertical and horizontal applications can make use of steel formwork. Renowned for its versatility and strength, steel formwork proves itself suitable for a multitude of construction projects. It serves as an ideal tool for crafting formwork not only for vertical elements such as walls, columns, and beams, but also for horizontal elements like slabs and foundations. Thanks to its inflexible nature, steel formwork guarantees meticulous shaping and ensures the concrete remains securely in place during pouring and curing. Moreover, the reusability of steel formwork renders it an economical option for construction projects necessitating frequent formwork alterations or repetitive utilization.

- Q: What are the different types of sealing systems used with steel formwork?

- There are primarily three types of sealing systems used with steel formwork: mechanical seals, chemical seals, and hydraulic seals. Mechanical seals involve using gaskets, rubber strips, or other mechanical devices to create a tight seal between the formwork components. Chemical seals involve applying chemical sealants or adhesives to fill any gaps or joints in the formwork, ensuring a watertight seal. Hydraulic seals use hydraulic pressure to create a seal, typically achieved through the use of specialized hydraulic clamps or seals. Each sealing system has its advantages and disadvantages depending on the specific requirements of the construction project.

- Q: How does steel formwork contribute to the overall sustainability of a structure?

- Steel formwork contributes to the overall sustainability of a structure in several ways. Firstly, steel formwork is durable and reusable, which minimizes waste and reduces the need for new materials in subsequent construction projects. This not only reduces the environmental impact but also saves costs in the long run. Additionally, steel formwork allows for efficient and precise construction, which reduces the overall construction time and energy consumption. Lastly, steel formwork can withstand harsh weather conditions and has a longer lifespan, ensuring the longevity and resilience of the structure, thus reducing the need for frequent repairs or replacements.

- Q: How does steel formwork contribute to the overall safety of workers?

- Steel formwork contributes to the overall safety of workers in several ways. Firstly, steel formwork is known for its strength and durability, providing a stable and secure structure for workers to perform their tasks. This stability minimizes the risk of accidents and collapses, ensuring the safety of workers. Additionally, steel formwork is designed to be fire-resistant, offering protection in case of fire emergencies. This feature significantly reduces the risk of injuries and provides workers with valuable time to evacuate the area safely. Moreover, steel formwork is engineered to be resistant to various weather conditions, such as strong winds and heavy rains. This resistance prevents formwork from becoming unstable or collapsing during adverse weather, minimizing the risk of accidents and injuries for workers on-site. Furthermore, steel formwork is typically designed with safety features such as non-slip surfaces and handrails, enhancing worker safety by providing better grip and stability when moving around the structure. These features help prevent slips, trips, and falls, which are common causes of accidents on construction sites. Another important aspect is that steel formwork is reusable and can be easily assembled and disassembled. This reduces the need for workers to carry heavy materials or tools, decreasing the risk of strain injuries and fatigue-related accidents. Lastly, steel formwork is designed to ensure proper support and alignment, minimizing the risk of structural failures or collapses during concrete pouring. This precise alignment ensures the stability of the structure and reduces the likelihood of accidents that could endanger workers' safety. In conclusion, steel formwork plays a crucial role in enhancing the overall safety of workers. Its strength, durability, fire resistance, weather resistance, non-slip surfaces, and proper support contribute significantly to creating a secure working environment, reducing the risk of accidents, injuries, and structural failures.

- Q: What are the different types of lifting systems used in steel formwork?

- There are several types of lifting systems used in steel formwork, including manual lifting systems, mechanical lifting systems, and hydraulic lifting systems. Manual lifting systems involve the use of manual labor and equipment, such as cranes or hoists, to lift and move the steel formwork. Mechanical lifting systems utilize mechanical devices, such as electric winches or chain blocks, to lift and transport the formwork. Hydraulic lifting systems utilize hydraulic power to lift and lower the steel formwork, providing greater control and precision in the lifting process.

- Q: How does steel formwork contribute to the overall durability of a structure?

- There are several ways in which steel formwork enhances the overall durability of a structure. Firstly, its resistance to wear and tear allows it to withstand the heavy loads and pressures exerted during construction, preventing any deformations or damages. This ensures accurate construction and maintains the structure's integrity. Furthermore, steel formwork exhibits excellent dimensional stability, retaining its shape and size even under extreme conditions like high temperatures or moisture exposure. This stability ensures that the concrete poured into the formwork maintains its desired shape and structural strength, resulting in a more durable structure. Additionally, steel formwork offers superior strength and rigidity compared to other materials. This strength allows it to support heavy concrete loads without any deformation or collapse, ensuring the stability and security of the structure. This is particularly important for large-scale structures such as bridges or high-rise buildings, where the formwork must bear significant loads for extended periods. Moreover, steel formwork is highly resistant to corrosion, a common cause of deterioration in construction materials. This resistance protects the formwork from environmental factors like moisture or chemicals, enhancing the structure's overall durability by minimizing the risk of corrosion-related damages. Lastly, the reusability of steel formwork contributes to both the sustainability of the construction process and cost-effectiveness. By being able to reuse the formwork multiple times, the need for additional materials and resources is reduced, resulting in less waste and lower construction costs. Additionally, the ability to properly maintain and inspect the formwork before each reuse enhances its durability and longevity. In conclusion, steel formwork is crucial in enhancing the overall durability of a structure. Its resistance to wear and tear, dimensional stability, strength, corrosion resistance, and reusability all contribute to the construction of a strong and long-lasting structure, ensuring its integrity and minimizing the risk of structural failures or damages over time.

- Q: Can steel formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel formwork can be used for both cast-in-place and precast concrete construction. Steel formwork is versatile and durable, making it suitable for various construction methods. It can be easily assembled and disassembled, allowing for efficient use in both cast-in-place and precast concrete projects.

- Q: Can steel formwork be used for curved or irregularly shaped structures?

- Yes, steel formwork can be used for curved or irregularly shaped structures. Steel formwork is highly flexible and can be easily customized to match the desired shape or form of the structure. Its strength and durability make it suitable for various construction projects, including those that involve unique or unconventional designs.

- Q: How does steel formwork affect the overall fire resistance of a building?

- The overall fire resistance of a building is not directly influenced by steel formwork. The primary determinant of fire resistance in a building is the materials used for structural components like columns, beams, and floors. However, steel formwork can indirectly affect the fire resistance of a building in several ways. To begin with, steel formwork is commonly employed in the construction of concrete structures. Concrete possesses excellent fire resistance properties since it is a non-combustible substance. When steel formwork is utilized to shape concrete, it aids in the creation of a fire-resistant structure by providing a robust and enduring framework for the concrete to be poured into. Consequently, this guarantees that the structure will remain intact even under high temperatures and prevent the building from collapsing in the event of a fire. Furthermore, steel formwork can also contribute to a building's fire resistance due to its ability to withstand extreme heat. Unlike other formwork materials like wood or plastic, steel formwork is less susceptible to burning or melting. As a result, even in the occurrence of a fire, the steel formwork will not contribute to the propagation of flames or the emission of toxic fumes. This aspect helps to contain the fire and minimize its impact on the overall fire resistance of the building. Lastly, steel formwork can indirectly impact a building's fire resistance by facilitating the installation of fire protection measures. By providing a smooth and sturdy surface, steel formwork allows for the easy application of fire-resistant coatings such as intumescent paint or fireproof sprays. These coatings enhance the fire resistance of the structure by adding an extra layer of protection against heat transfer and fire spread. In conclusion, although steel formwork itself does not directly affect the fire resistance of a building, it plays a vital role in constructing a fire-resistant structure. This is achieved through its provision of a sturdy framework for concrete, its ability to withstand high temperatures, and its facilitation of the installation of fire protection measures.

Send your message to us

Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches