Steel Frame Formworks Used in Different Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

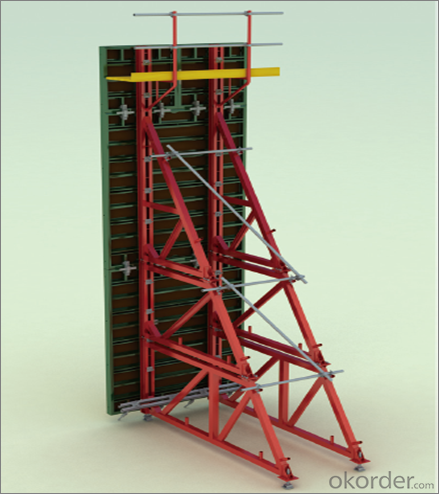

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How does steel frame formwork handle concrete pouring in rainy weather conditions?

- Steel frame formwork is well-suited to handle concrete pouring in rainy weather conditions. Its sturdy structure and robust design ensure that it can withstand the additional weight and pressure exerted by wet concrete. Additionally, steel is highly resistant to moisture and does not corrode easily, minimizing the potential for damage. This makes it a reliable choice for rainy weather conditions, as it can maintain its integrity and provide the necessary support for proper concrete pouring and curing.

- Q: How does steel frame formwork affect the overall weight of a construction project?

- Steel frame formwork can significantly affect the overall weight of a construction project. Compared to traditional timber formwork, steel frame formwork is generally much lighter. This reduced weight has several advantages. Firstly, it makes the transportation and handling of the formwork much easier and more efficient. Steel frame formwork can be easily dismantled, transported, and reassembled at different locations, which is especially beneficial for large-scale construction projects that require frequent formwork repositioning. Secondly, the reduced weight of steel frame formwork allows for a quicker and more streamlined construction process. The lighter formwork can be easily lifted and moved by construction workers, allowing for faster installation and removal. This efficiency translates into shorter construction times and reduced labor costs. Additionally, the lighter weight of steel frame formwork has a positive impact on the load-bearing capacity of the overall structure. By reducing the weight of the formwork, the structural design can allocate a greater proportion of the load-bearing capacity to the actual building materials, such as concrete or steel beams. This results in a more robust and efficient construction, with greater durability and safety. Overall, steel frame formwork significantly reduces the overall weight of a construction project, resulting in easier transportation, faster construction, and improved load-bearing capacity. Its lightweight nature contributes to the overall efficiency, cost-effectiveness, and quality of the construction process.

- Q: Can steel frame formwork be used for both single-sided and double-sided concrete pouring?

- Indeed, steel frame formwork proves itself as a viable option for both single-sided and double-sided concrete pouring endeavors. Its adaptability and ease of adjustment allow for seamless accommodation of varying pouring needs. When it comes to single-sided pouring, the formwork is skillfully positioned on a solitary side of the structure, whereas for double-sided pouring, the formwork assumes its rightful place on both sides. In either case, the steel frame formwork dutifully offers the essential support and stability required to contain the concrete and ensure its proper setting. Furthermore, its durability enables it to withstand the considerable pressure exerted by the concrete, rendering it suitable for both types of pouring operations.

- Q: How much is the glass door with a frame

- The stainless steel frame (304 2.2) toughened glass (6 mm glass) 420 yuan / square meter manual 60

- Q: Can steel frame formwork be used for both cast-in-place and precast concrete elements?

- Yes, steel frame formwork can be used for both cast-in-place and precast concrete elements. Steel frame formwork is a versatile and reusable system that can be easily adjusted and customized to accommodate various shapes and sizes of concrete elements. It provides strong support and stability during the pouring and curing process, ensuring accurate and precise results for both cast-in-place and precast concrete construction. The steel frames can be easily assembled, disassembled, and transported, making them suitable for use in different construction projects. Additionally, steel frame formwork can withstand the high pressures and forces exerted by the concrete during casting, ensuring the structural integrity of the elements. Overall, steel frame formwork is a reliable and efficient solution that can be used for both cast-in-place and precast concrete elements.

- Q: How does steel frame formwork handle concrete pouring and curing processes?

- Steel frame formwork is a popular choice in construction due to its durability, strength, and adaptability. When it comes to handling concrete pouring and curing processes, steel frame formwork offers several advantages. Firstly, steel frame formwork provides a stable and rigid structure that can withstand the pressure and weight of wet concrete. The steel frames are designed to support the weight of the concrete, ensuring that it does not deform or collapse during the pouring process. This stability is crucial to ensure the structural integrity of the concrete elements being formed. Additionally, steel frame formwork allows for precise control over the pouring process. The frames can be easily adjusted and aligned to achieve the desired shape and dimensions of the concrete element. This level of flexibility ensures that the concrete is poured accurately, minimizing the need for rework or corrections later on. Furthermore, steel frame formwork facilitates the curing process of the concrete. The frames can be left in place while the concrete sets and cures, providing continuous support and protection. This is particularly important in large-scale construction projects where the concrete needs time to harden and gain strength. The steel frames also act as a barrier against external factors such as temperature changes, preventing rapid drying or excessive moisture loss during the curing process. Moreover, steel frame formwork is reusable and can be easily disassembled and reassembled for multiple construction projects. This not only reduces construction costs but also minimizes waste and environmental impact. In summary, steel frame formwork is specifically designed to handle the concrete pouring and curing processes efficiently. Its stability, flexibility, and durability make it an ideal choice for construction projects, ensuring the successful execution of concrete elements while maintaining the structural integrity and quality of the final product.

- Q: Can steel frame formwork be used for both flat and sloped slab construction?

- Yes, steel frame formwork can be used for both flat and sloped slab construction.

- Q: Steel frame wood fire doors can replace steel fire door

- Can not, wood fire doors fire rating is relatively low, can not replace the steel fire doors

- Q: How does steel frame formwork prevent the formation of concrete shrinkage cracks?

- Steel frame formwork prevents the formation of concrete shrinkage cracks by providing strong and rigid support to the concrete during the curing process. It ensures that the concrete remains in its desired shape and position, preventing any movement or displacement that could lead to crack formation. Additionally, the steel frame formwork helps in evenly distributing the forces and stresses exerted by the curing concrete, minimizing the potential for shrinkage cracks to develop.

- Q: How does steel frame formwork contribute to the overall sustainability of the construction industry?

- Steel frame formwork contributes to the overall sustainability of the construction industry in several ways. Firstly, steel is a highly durable material that can withstand the rigors of construction and can be reused multiple times. This means that steel frame formwork can be used for multiple projects, reducing the need for new formwork materials and minimizing waste. Additionally, steel frame formwork allows for efficient construction processes. The use of steel frames provides a strong and stable support system for concrete during the pouring and curing stages, resulting in high-quality structures. The precision and accuracy of steel formwork also ensure that less material is wasted, reducing the overall environmental impact of construction projects. Furthermore, steel is a recyclable material, meaning that at the end of its lifespan, it can be melted down and used to create new steel products. This promotes a circular economy and reduces the demand for virgin materials, ultimately saving energy and reducing greenhouse gas emissions associated with the production of new materials. Lastly, steel frame formwork can contribute to the sustainability of the construction industry by reducing the overall construction time. The use of prefabricated steel formwork systems allows for faster and more efficient construction processes, minimizing disruption to the environment and local communities. In conclusion, steel frame formwork contributes to the overall sustainability of the construction industry through its durability, reusability, recyclability, and efficiency. By reducing waste, conserving resources, and promoting a circular economy, steel formwork helps to minimize the environmental impact of construction projects and supports the long-term sustainability of the industry.

Send your message to us

Steel Frame Formworks Used in Different Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches