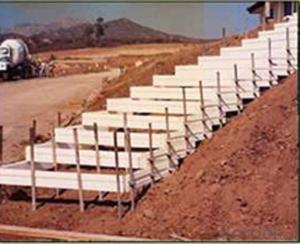

Scaffolding For Painters Formwork Scaffolding Bs1139 For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

- Q: Can steel frame formwork be used for both precast and cast-in-place concrete beams?

- Yes, steel frame formwork can be used for both precast and cast-in-place concrete beams. Steel frame formwork is a versatile and durable system that can be easily adapted to various construction methods. For precast beams, the steel frame formwork is used to create the mold or template in which the concrete is poured and cured. Once the concrete has hardened, the formwork can be removed, leaving behind a precast beam that can be transported and installed at the construction site. Similarly, for cast-in-place concrete beams, steel frame formwork is used to create the temporary mold or template in which the concrete is poured. The formwork provides support and shape to the concrete during the pouring and curing process. Once the concrete has set, the formwork can be removed, leaving behind a cast-in-place beam that is integrated into the overall structure. Steel frame formwork offers several advantages for both precast and cast-in-place beams. It provides high strength and stability, allowing for the construction of beams with complex shapes and sizes. The steel frame formwork can be easily assembled and disassembled, making it efficient and cost-effective. Additionally, steel frame formwork is reusable, which reduces waste and promotes sustainability in construction projects. In conclusion, steel frame formwork is a suitable choice for both precast and cast-in-place concrete beams. Its versatility, durability, and ease of use make it a preferred formwork system for various construction methods.

- Q: How does steel frame formwork compare to precast concrete formwork?

- Steel frame formwork and precast concrete formwork are two popular methods used in construction for forming concrete structures. Here is a comparison of both methods: 1. Construction Process: Steel frame formwork involves the use of steel frames, which are assembled on-site and then filled with concrete. Precast concrete formwork, on the other hand, involves manufacturing concrete panels or modules off-site and then transporting and installing them at the construction site. This difference in the construction process can impact the overall project timeline. 2. Customization: Steel frame formwork provides more flexibility in terms of customization. The steel frames can be easily adjusted and modified to accommodate different shapes and sizes, allowing for more complex architectural designs. Precast concrete formwork, although it can be customized to some extent, is limited by the precast modules' predetermined shapes and sizes. 3. Reusability: Steel frame formwork can be reused multiple times on different projects, making it a cost-effective option in the long run. The frames can be cleaned, repaired, and used again, reducing waste and construction costs. Precast concrete formwork, however, is not reusable and typically serves a single project. 4. Strength and Durability: Steel frame formwork is known for its high strength and durability, which makes it suitable for heavy-duty projects. The steel frames provide excellent support and stability, ensuring the structure's integrity. Precast concrete formwork also offers good strength and durability, but it may not be as robust as steel frame formwork in certain applications. 5. Cost: Steel frame formwork typically requires a higher initial investment due to the cost of materials and fabrication. However, its reusability can offset these costs in the long term. Precast concrete formwork may have a lower initial cost, but the lack of reusability makes it more expensive for multiple projects. 6. Construction Speed: Steel frame formwork allows for faster construction progress as the frames can be quickly assembled and disassembled on-site. Precast concrete formwork, on the other hand, may require additional time for manufacturing, transportation, and installation, which can impact the overall project schedule. In conclusion, both steel frame formwork and precast concrete formwork have their advantages and disadvantages. Steel frame formwork offers flexibility, reusability, and strength, while precast concrete formwork provides cost-effectiveness and faster installation in some cases. The choice between the two methods ultimately depends on the specific project requirements, budget, and timeline.

- Q: Are there any limitations to the size or shape of structures that can be constructed using steel frame formwork?

- Yes, there are limitations to the size and shape of structures that can be constructed using steel frame formwork. The size of the structure is limited by the length and dimensions of the steel frames available, as well as the weight-bearing capacity of the formwork system. Additionally, complex and intricate shapes may be challenging to achieve with steel frame formwork, as it is typically designed for more straightforward and repetitive structures.

- Q: Are there any environmental benefits to using steel frame formwork?

- Yes, there are several environmental benefits to using steel frame formwork in construction projects. Firstly, steel is a highly durable material that can be used repeatedly without losing its structural integrity. This means that steel formwork can be used for multiple construction projects, reducing the need for new formwork materials and minimizing waste generation. Additionally, steel frame formwork can be easily dismantled and reassembled, making it more versatile and adaptable for different construction needs. Furthermore, steel is a recyclable material, meaning that at the end of its life cycle, it can be recycled and used to produce new steel products. This reduces the demand for new steel production and the associated environmental impacts, such as mining and energy consumption. Moreover, steel frame formwork can contribute to energy efficiency in construction. Due to its superior strength and load-bearing capacity, steel formwork allows for the construction of more slender and lightweight structures. This leads to a reduction in the overall material used in construction, resulting in energy savings during the manufacturing, transportation, and installation processes. In conclusion, the use of steel frame formwork offers several environmental benefits, including durability, reusability, recyclability, and energy efficiency. By choosing steel frame formwork, construction projects can minimize waste generation, conserve resources, and reduce their environmental footprint.

- Q: Is steel frame formwork adjustable in height?

- Yes, steel frame formwork is adjustable in height. Steel frames are designed with adjustable legs or telescopic props that allow for easy and precise height adjustments. This feature enables the formwork to be adapted to different construction requirements and allows for flexibility in the construction process. Additionally, the adjustable height feature ensures that the formwork can be easily aligned with the desired level and slope of the concrete structure being formed.

- Q: Can steel frame formwork be used for both residential and industrial flooring?

- Yes, steel frame formwork can be used for both residential and industrial flooring. Its strength and durability make it suitable for various construction applications, providing stability and support for concrete pouring and ensuring a solid foundation for both residential and industrial flooring.

- Q: Can steel frame formwork be used for circular or cylindrical structures?

- Yes, steel frame formwork can be used for circular or cylindrical structures. Steel frame formwork is a versatile and flexible system that can be easily adjusted to form various shapes and sizes, including circular or cylindrical structures. The steel frames are designed to be adjustable and can be curved or bent to match the desired shape of the structure. Additionally, the formwork panels can be attached to the steel frames to create a seamless and continuous mold for pouring concrete. This allows for the construction of circular or cylindrical structures with precise dimensions and smooth finishes. Overall, steel frame formwork is a suitable choice for forming circular or cylindrical structures due to its adaptability and ability to create complex shapes.

- Q: Are there any specific design considerations for steel frame formwork?

- Yes, there are several specific design considerations for steel frame formwork. Firstly, the design should ensure that the steel frame is strong and rigid enough to support the weight of the concrete being poured. This involves determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another important consideration is the ease of assembly and disassembly of the formwork. Steel frame formwork should be designed in a way that allows for quick and efficient installation and removal, as this can significantly impact the overall construction timeline and cost. Additionally, the design should take into account the potential for lateral forces, such as wind or concrete pressure, and ensure that the steel frame formwork is adequately braced and supported to resist these forces. This may include the use of diagonal bracing or tie rods to increase stability and prevent deformation of the formwork. The design should also address the issue of formwork deflection. Steel frames may have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and properly designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires attention to detail in terms of material selection, surface treatment, and overall durability of the formwork components. In summary, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

- Q: Beam column section dimensions of multi story steel frame structures

- Simply supported beam in accordance with L/12~L/18.Continuous beam is estimated according to L/15~L/25.

- Q: How does steel frame formwork impact the overall sustainability of a project?

- Steel frame formwork can greatly enhance the overall sustainability of a project in several ways. Firstly, steel is a highly durable material that can withstand multiple uses, minimizing the need for frequent replacements and reducing waste generation. Additionally, steel frame formwork allows for efficient and precise construction, reducing material wastage and minimizing the overall environmental impact of the project. Moreover, steel is a recyclable material, and at the end of its lifespan, it can be easily recycled, further contributing to the sustainability of the project. Overall, steel frame formwork promotes sustainability by enhancing durability, reducing waste, and facilitating recycling.

Send your message to us

Scaffolding For Painters Formwork Scaffolding Bs1139 For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches