Ic Grade Solar Silicon Wafer 3kw Off-Grid Solar Energy Generator System for Home Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

156x156 A Grade B Grade PV Silicon Solar Cell for Solar Panel

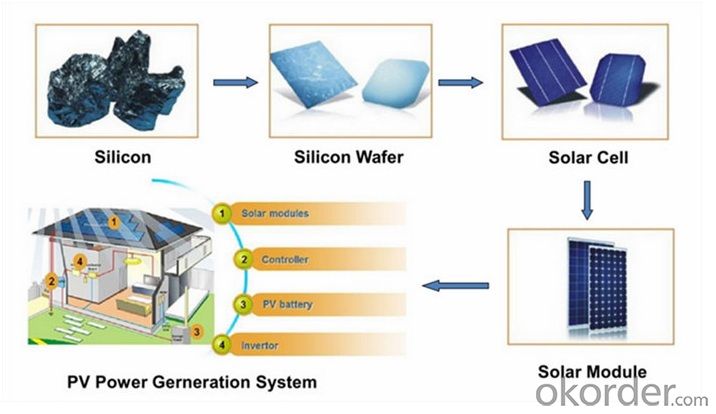

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Physical characteristics

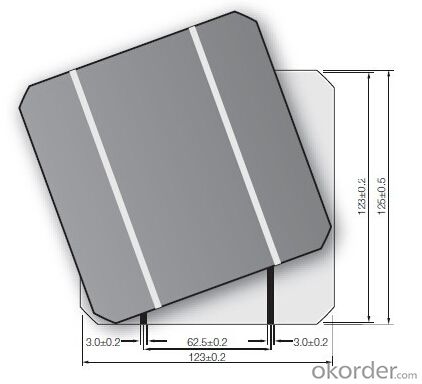

Dimension | 156mm X 156 mm ±0.5mm |

Wafer Thickness | 200um ±30um |

Front(-) | Four 1.1mm wide bus bars(silver) with distance 39mm, Acid texturized surface with blue silicon nitride AR coating. |

Back(+) | 2.4mm wide silver/aluminum soldering pads, aluminum back surface field. |

Product Pictures

- Q: Begged monocrystalline silicon rod is to use what tools and equipment to cut into silicon. What are the most commonly used methods. Loss big? Thank you

- Common cutting methods for diamond wire cutting and sand cutting

- Q: How does the texturing process affect the performance of a solar silicon wafer?

- The texturing process has a significant impact on the performance of a solar silicon wafer. It enhances light absorption by creating a rough surface that reduces the reflectivity of the wafer. This increased light absorption improves the efficiency and overall performance of the solar cell, leading to higher power output and better energy conversion.

- Q: What is the impact of temperature on the performance of solar silicon wafers?

- The performance of solar silicon wafers is significantly affected by temperature. Higher temperatures can lead to a decrease in the efficiency of solar cells, causing a reduction in power output. This is primarily due to the increase in resistive losses and the decrease in the voltage of the solar cells at higher temperatures. Additionally, excessive heat can degrade the materials used in solar cells, leading to a decline in their overall performance and lifespan. Therefore, maintaining optimal operating temperatures is crucial for maximizing the efficiency and longevity of solar silicon wafers.

- Q: Is a wafer a silicon wafer and a wafer?Please try to speak more popular, can be said to be made of silicon wafers do

- An uncut monocrystalline silicon material is a thin wafer called a wafer

- Q: Can solar silicon wafers be used in recreational vehicles (RVs)?

- Yes, solar silicon wafers can be used in recreational vehicles (RVs) to generate electricity from sunlight and power various appliances and systems within the vehicle.

- Q: What is the typical lifespan of a solar silicon wafer?

- The typical lifespan of a solar silicon wafer can vary depending on various factors, such as the quality of the wafer, manufacturing processes, and environmental conditions. However, on average, a well-maintained and properly installed solar silicon wafer can last for around 25 to 30 years.

- Q: Can solar silicon wafers be used in other electronic applications besides solar panels?

- Yes, solar silicon wafers can be used in other electronic applications besides solar panels. They can be utilized in various electronic devices such as semiconductors, integrated circuits, and microchips. Their excellent electrical properties make them suitable for a wide range of electronic applications beyond solar panels.

- Q: How are solar silicon wafers protected from theft?

- Solar silicon wafers are typically protected from theft through various security measures. These may include surveillance cameras, alarm systems, secure storage facilities, and restricted access to the production areas. Additionally, tracking technologies like RFID tags or GPS can be used to monitor and locate stolen wafers. These measures aim to deter theft, detect any unauthorized activity, and enable quick recovery in case of theft.

- Q: What are the different materials used for front contacts in solar silicon wafers?

- The different materials used for front contacts in solar silicon wafers include silver, aluminum, and copper. These materials are chosen for their electrical conductivity and compatibility with the silicon wafer, allowing for efficient collection and transport of the generated solar energy.

- Q: Can solar silicon wafers be used in solar-powered telecommunications?

- Yes, solar silicon wafers can be used in solar-powered telecommunications. These wafers are commonly used in the production of photovoltaic cells, which convert sunlight into electricity. Since solar-powered telecommunications systems rely on harnessing solar energy to power their operations, solar silicon wafers are an essential component in the generation of electricity from sunlight.

Send your message to us

Ic Grade Solar Silicon Wafer 3kw Off-Grid Solar Energy Generator System for Home Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords