Hig Efficient &Easy Installation Wholely Assembled Box Girder Template

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

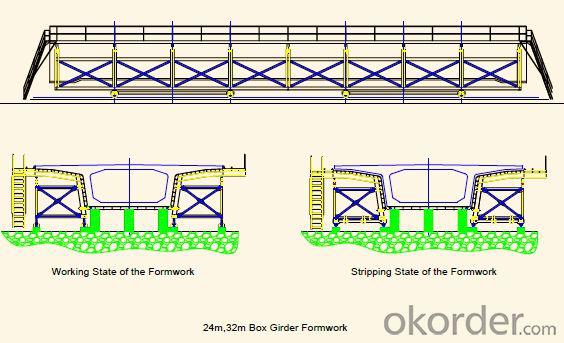

Wholely Assembled Box Girder

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: What is the foundation beam template

- I was in the study of this problem, it should be the construction is not based on beam design has been explained, but the quota is a little different, the beam bottom cushion or other basis should be the beam, it should be suspended under the general frame or beam. The difference is that the two side support and the three side support. Usually the explanation is still looking for evidence.

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- Span multiplied by 1/1000~3/1000, can not be so precise, the general is probably about two or three cm

- Q: What kind of frame beam formwork

- Frame beam template, single beam, continuous beam template section, beam set beam template in the middle section.

- Q: What is the wire mesh in front of the foundation beam

- Beams are reinforced, how to put into the template? How can we ensure that the concrete does not flow out? Wire netting is the best way

- Q: For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- Plate side mode *2 is the circumference of the board (minus column protruding part) multiplied by the thickness of the plate 0.1M

- Q: The formula for the calculation of beam, concrete and brick

- The area of the template (= the height of the side of the beam and the bottom of the beam)The cast-in-place concrete beams (including foundation beam) template, according to three surface width multiplied by the beam length, measured in square meters.

- Q: Seeking beam, plate template engineering quantity

- The second beam template (bottom area +2* side area): (2.6*3- wall thickness) * (0.2+ (0.4-0.12) *2) *2-0.2*0.25*4 [the main beam and the secondary beam transfer area] -0.2*0.4*2*4 [the main beam and secondary beam transfer area]

- Q: I would like to ask the three sides of the template is calculated on the surface of which is the three? Novice do not understand thank you

- The utility model relates to a three surface template beam (both sides of the beam and the bottom surface of the beam), and the other is a two side formwork beam (two sides of the beam)

- Q: When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

- Q: 10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- When the bottom formwork of the reinforced concrete slab with a span of 5m is removed, the concrete strength should be greater than or equal to 75% of the standard value of concrete cube compressive strength.

Send your message to us

Hig Efficient &Easy Installation Wholely Assembled Box Girder Template

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords