Assembly Precision Box Girder Steel Template

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

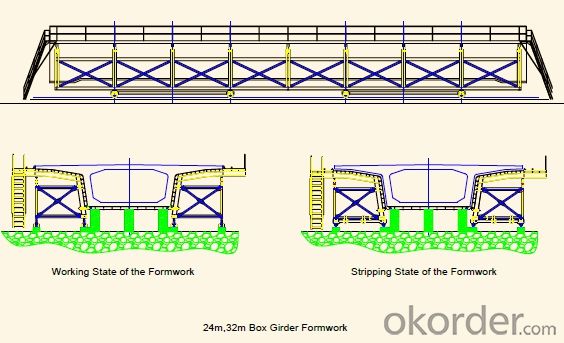

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 1, in order to prevent the concrete weight and construction load to other beam and plate template pendulous; if there is no design provisions, the arch height is the length of the cross beam and plate 1/1000~3/1000; (general wood template for 1.5/1000~3/1000; steel template for 1.5/1000~2/1000.)

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- It is not deducted from the length to beam or column just didn't count on this side overlap, I figure out part of the coil

- Q: What is a large volume template? How much is the cross section of the beam, belonging to the large volume template?

- According to the "dangerous method" sub project safety management of the construction quality of [2009]87, the height of more than 5m, the total construction loads greater than 10kN/m2, or the template support system concentrated line load greater than 15kN/m to prepare special construction scheme

- Q: How to calculate the amount of beam template? FiveKL2: cross section size of 0.3*0.6, thickness of the 0.12 beams, 10.9 JingchangAsk: how to calculate the amount of formwork works? How to calculate the height of support?Calculation formula

- According to the calculation of the expansion area, the height of support according to the bottom elevation

- Q: Beam plate template is composed of the bottom template and what

- The template will be installed to expand into one piece, each piece of the area is Si=F*A*B, the formula, F coefficient

- Q: There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The general situation is calculated according to the contact area between the concrete and the template

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- The side plate of the plate is the circumference of the plate (minus the protruding part of the column) multiplied by the thickness of the plate 0.1m.Beam slab:Plate beam T beam box girder is divided into cast in place PC box girder and steel box girderBeam type structural member composed of steel plates. The basic section is I-shaped, upper and lower transverse wing plate is vertical plate, the middle name web. Some plates are welded with reinforcing ribs. According to the combination method, it can be divided into welding plate beam, high strength bolt plate beam and dissimilar steel plate beam. Reinforced concrete slab beam.

- Q: The calculation formula of the beam column for the construction of the concrete and the use of the template area of the detailed point of the best thank you

- Refer to JGJ 162-2008 construction formwork safety technical specifications

- Q: A set of 50 m T beam steel template weight

- So as to complete the precast beam and slab

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- Column according to the circumference of the column by column height, Liang Anliang on both sides of the beam after the end of the beam length, according to the net floor area of the room (excluding wall width or Liang Kuan) calculation.

Send your message to us

Assembly Precision Box Girder Steel Template

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords